Device for producing ship propeller

A technology for propellers and rotating devices, which is applied in the field of special manufacturing equipment for ship propellers, and can solve problems such as time-consuming individual differences, more energy consumption, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

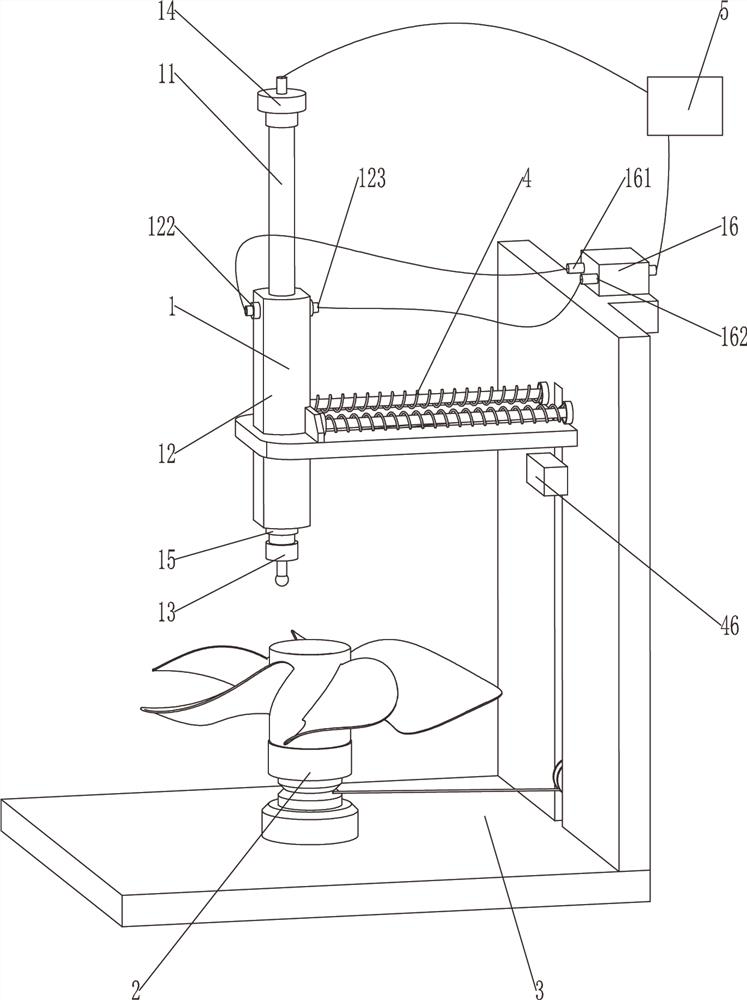

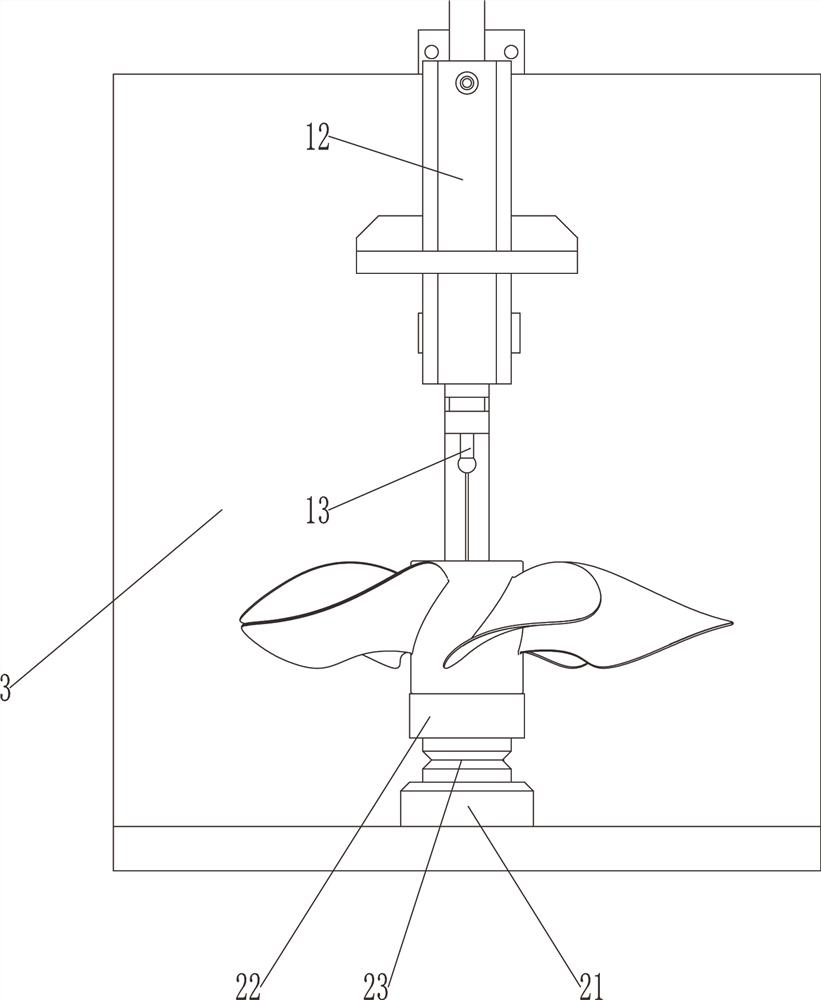

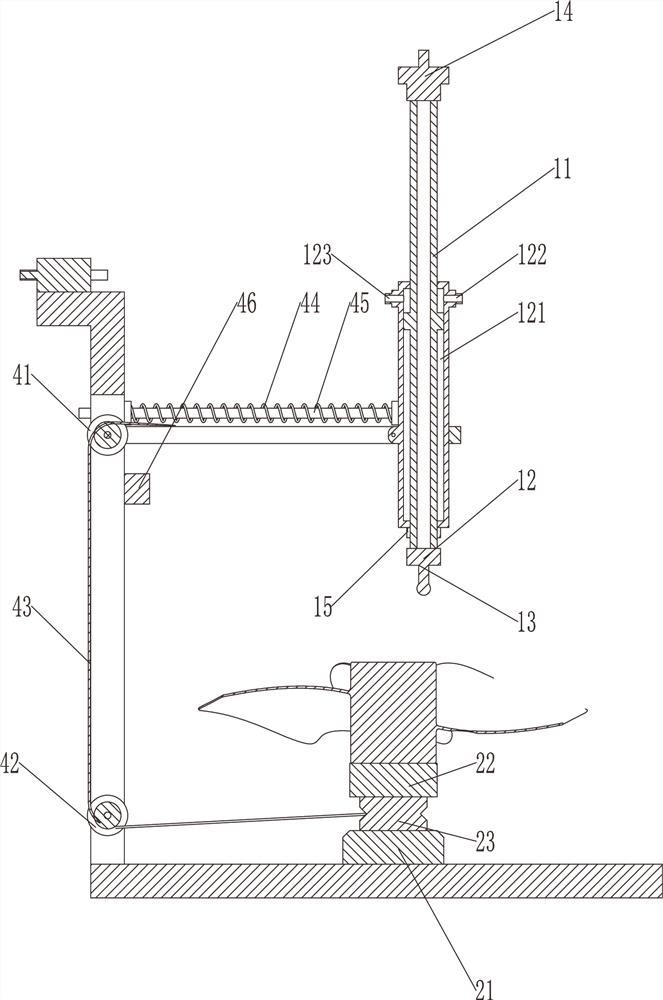

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 6 , a device for producing ship propellers, comprising a constant pressure floating grinding head 1, a bottom rotating device 2, a frame 3, a left and right moving device 4 and an air source 5, the air source 5 provides compressed air for the machine, and the The bottom rotating device 2 is set at the bottom of the frame 3, which is used to clamp the propeller and provide rotational power for it. The constant-pressure floating grinding head 1 is set on the frame 3, and can follow the rotation of the propeller and float up and down on its curved surface when compressed air is supplied. Press and touch for grinding. The left and right moving device 4 is connected with the constant pressure floating grinding head 1 and the bottom rotating device 2. When the bottom rotating device 2 rotates, it can drive the constant pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com