Multi-source organic solid waste treatment system and method for pollutant recycling

A disposal system, a technology for organic solid waste, applied in the direction of biological organic part treatment, combustion method, organic fertilizer equipment, etc., to achieve significant economic and environmental benefits, good demonstration benefits, and improved energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

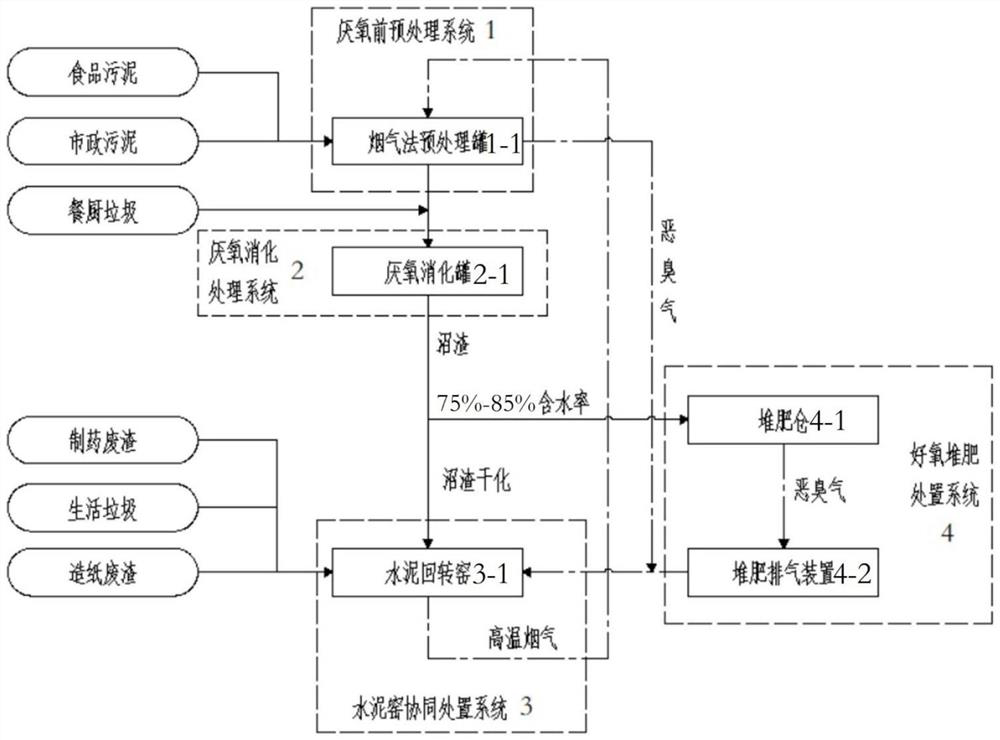

[0029] Such as figure 1 As shown, a multi-source organic solid waste disposal system for pollutant resource utilization provided in this embodiment is characterized in that it includes an anaerobic pretreatment system 1, an anaerobic digestion treatment system 2, and a cement kiln co-processing system 3 , aerobic composting disposal system 4;

[0030] The solid outlet of the anaerobic pretreatment system 1 leads to the anaerobic digestion treatment system 2;

[0031] The biogas residue outlet of the anaerobic digestion treatment system 2 is connected to the cement kiln co-processing system 3 and the aerobic composting treatment system 4 respectively;

[0032] The malodorous gas exhaust port of the anaerobic pretreatment system 1 and the malodorous gas exhaust port of the aerobic composting disposal system 4 are jointly connected to the cement kiln co-processing system 3, and the high-temperature flue gas exhaust port of the cement kiln co-processing system 3 is connected to t...

Embodiment 2

[0041] This embodiment is a multi-source organic solid waste disposal method for recycling pollutants using the system provided in Embodiment 1, including the following steps:

[0042] 1) According to the different sources of pollutant organic solid waste, feed them into the anaerobic pretreatment system 1 and the cement kiln co-processing system 3 in different treatment systems;

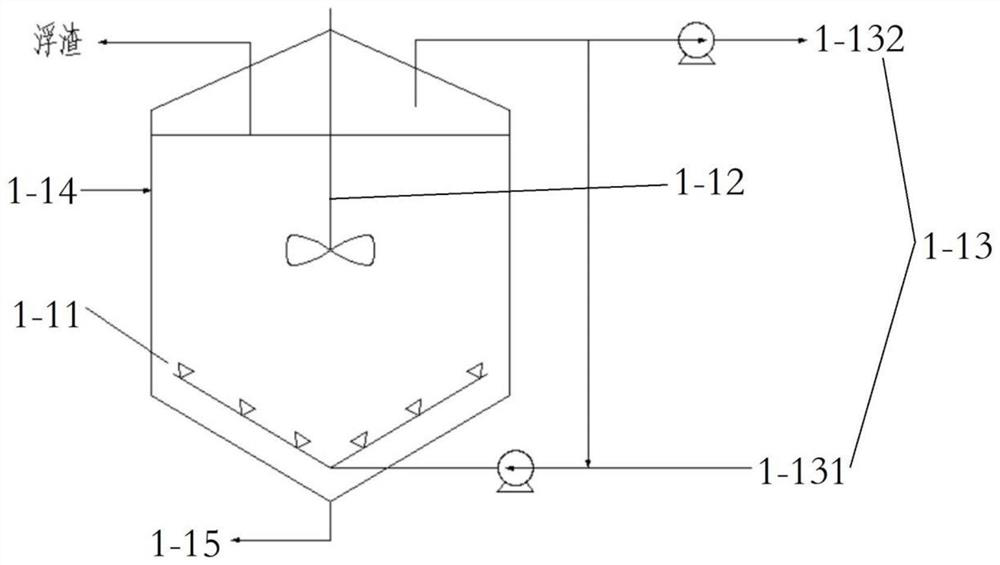

[0043] 2) Municipal sludge and food industry sludge are mixed and enter the flue gas method pretreatment tank 1, and pretreated sludge is obtained after high-temperature flue gas pretreatment. The food waste is pretreated by "sorting and removing impurities - crushing and pulping - three-phase separation" to obtain the oil phase and solid-liquid mixed phase, and then the pretreated sludge and the solid-liquid mixed phase obtained after pretreatment of the food waste After mixing, enter the anaerobic digestion tank 2 for anaerobic digestion;

[0044] 3) After the biogas residue digested by the anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com