High-pressure water jet spraying device carried on TBM and having sealing and anti-loosening functions

A high-pressure water jet and injection device technology, which is applied in the direction of injection devices, mining equipment, earthwork drilling and mining, etc., can solve the impact on the safety and stable operation of the high-pressure water-assisted rock breaking system, the reduced sealing of the high-pressure water jet injection device, strong Vibration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

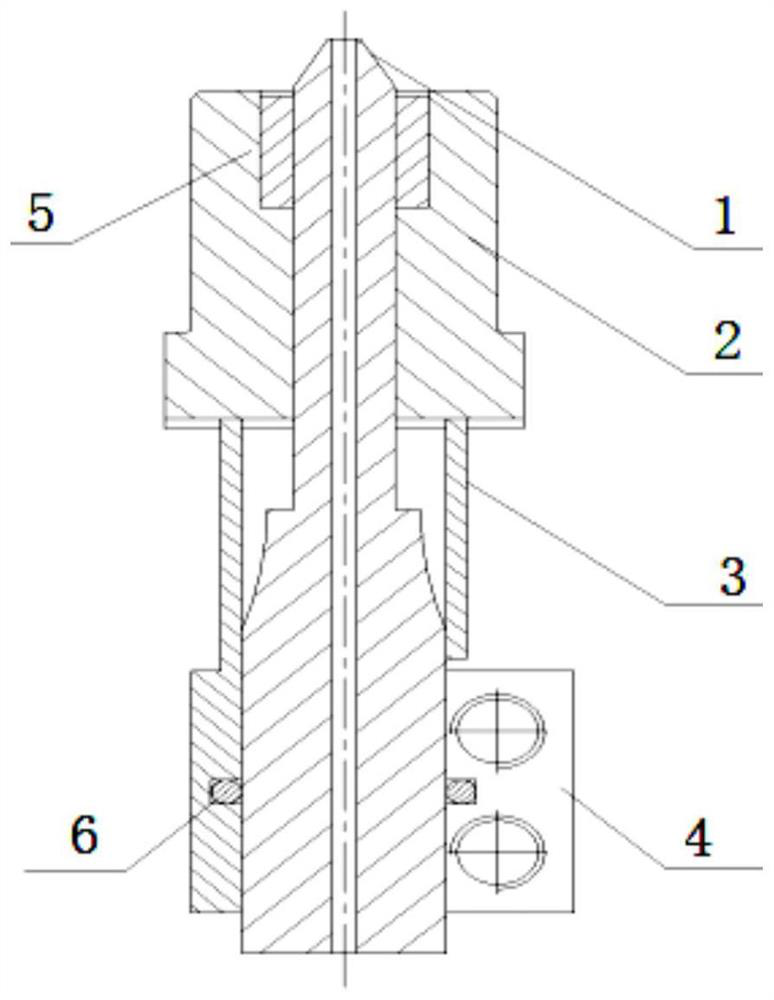

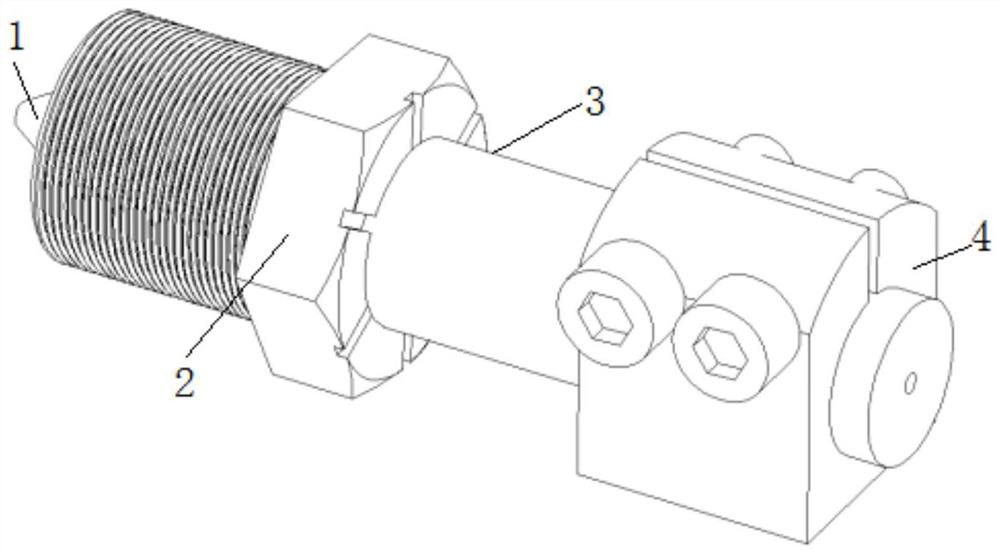

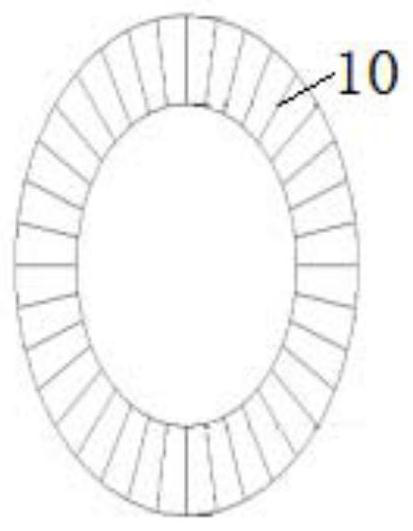

[0085] The embodiment of the present invention provides a high-pressure water jet injection device mounted on a TBM with a sealing and anti-loosening function, such as Figure 1-8 As shown, it includes: a high-pressure water jet injection device body, the high-pressure water jet injection device body includes a high-pressure hose, a water spray rod 14, and a water spray rod flange 8, and the high-pressure water jet injection device with a sealing and anti-loosening function It also includes: the sealing and anti-loosening structure of the high-pressure hose, the sealing and anti-loosening structure of the 8 bolts of the water spray rod flange, and the sealing and anti-loosening structure of the 14 screw washers and screw sleeves of the water spray rod. Among them, the high-pressure water jet injection device body includes a high-pressure hose, a water spray rod 14, and a water spray rod flange 8. Specifically, the water outlet end of the high-pressure water delivery system (hig...

Embodiment 2

[0121] On the basis of Embodiment 1, the high-pressure hose is connected to the water outlet of the high-pressure water delivery system, and the high-pressure water delivery system includes: a control box 24, and the control box 24 includes an outer box and an inner box. The control box 24 is installed in the guard 30, such as Figure 9-10 As shown, the protective device includes:

[0122] A protective box 301, the first installation cavity 302 is set in the protective box 301, the left and right sides of the outer box of the control box 24 are provided with first slots 241, and the left and right sides of the first installation cavity 302 are set The second installation cavity 303, the lower end of the second installation cavity 303 is a stepped structure;

[0123] The first connection assembly 304 is arranged symmetrically in the two second installation cavities 303, and the first connection assembly 304 includes: several first springs 3041, and a first horizontal installat...

Embodiment 3

[0131] On the basis of Embodiment 1 or 2, the high-pressure hose is connected to the water outlet of the high-pressure water delivery system, and the high-pressure water delivery system includes: a filter device 40, such as Figure 11-13 shown;

[0132] The filtering device 40 includes:

[0133] A first box 401, a second box 402 is arranged inside the first box 401;

[0134] The first processing assembly 403 is arranged between the first box body 401 and the second box body 402, and the first processing assembly 403 includes: a first driving motor 4031, which is arranged on the left inner wall of the first box body 401, The output shaft of the first driving motor 4031 is arranged along the left and right direction; the first bevel gear 4032 is fixedly connected to the output shaft of the first driving motor 4031; The second box body 402 mentioned above, and the front side of the first horizontal shaft 4033 runs through the front side of the second box body 402; the first gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com