Waste recovery device based on aluminum plate trimming

A waste recycling and plate cutting technology, which is applied to metal processing machinery parts, maintenance and safety accessories, presses, etc., can solve the problem that the feeding port cannot be automatically opened and closed, and achieve novel design, convenient centralized processing, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

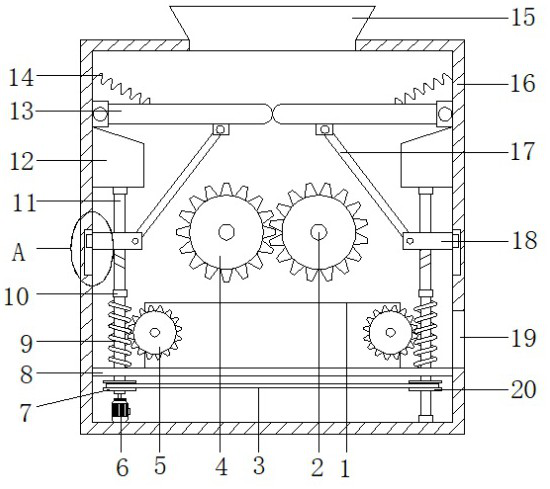

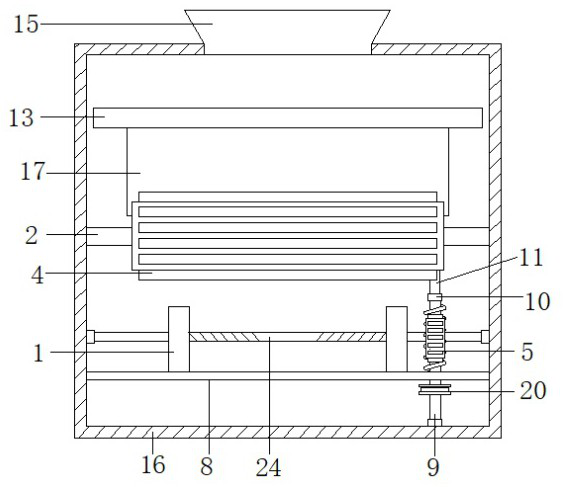

[0029] Refer Figure 1-3 : Trimming plate based on aluminum scrap recovery, comprising a housing 16, fixedly connected inside the box 16 with a separator 8 fall inside the aluminum scrap to avoid the power unit, the top of the separator 8 is provided with a compressed structure, automatically aluminum powder is compressed, for centralized processing, compression structure includes two longitudinally inside the casing 16 is rotatably connected to the two-way screw 24, the upper spacer 8 is provided with two lateral compression plate 1, when the bidirectional screw 24 forward, the control two compression plates 1 close to each other, automatically extruded aluminum scrap, the compression power mechanism provided on both sides of the structure, to provide for the overall operation of the power source, the structure is provided above the compression mechanism pulverized, automatic waste aluminum sheet was ground, pulverized mechanism comprises two longitudinal shaft inside the case 16 ...

Embodiment 2

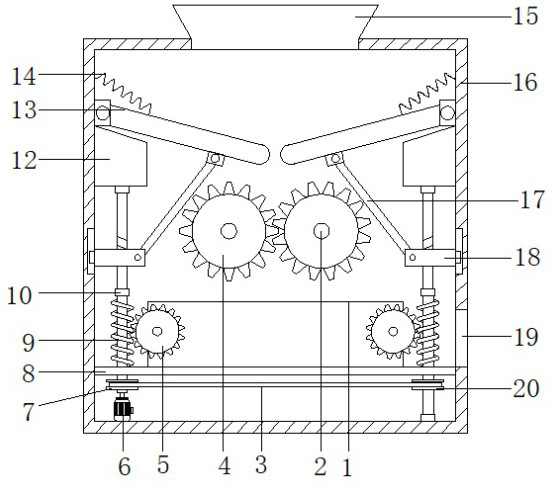

[0034] Refer Figure 2-6 : Trimming plate based on aluminum scrap recovery, this embodiment includes a case 16, fixedly connected inside the box 16 with a separator 8, the top of the separator 8 is provided with a compressed structure, automatic aluminum scraps compression, for centralized processing, compression power mechanism is provided on both sides of the structure, the structure is provided above the compression mechanism pulverized, automatic waste aluminum sheet was ground, above the shredder mechanism is provided to open and close mechanism, automatic control of the feed port opening together, reducing security risks, opening and closing the opening and closing mechanism includes two side plates 12 disposed above the stopper plate 13, and the two hinged panels 13 are hinged away from the inner wall of the casing 16, below the opening and closing of the hinge plate 13 connecting plate 17, the bottom end of the connecting plate 17 are hingedly movable block 18, movable bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com