Design method for flattening aluminum alloy thin plate

A design method and technology of aluminum alloy, applied in the direction of metal processing equipment, ejection equipment, feeding device, etc., can solve the problems of insufficient flatness of aluminum alloy sheet, high labor intensity of operators, large floor space of leveling machine, etc., and achieve Reasonable structure, reduced labor intensity, fast extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

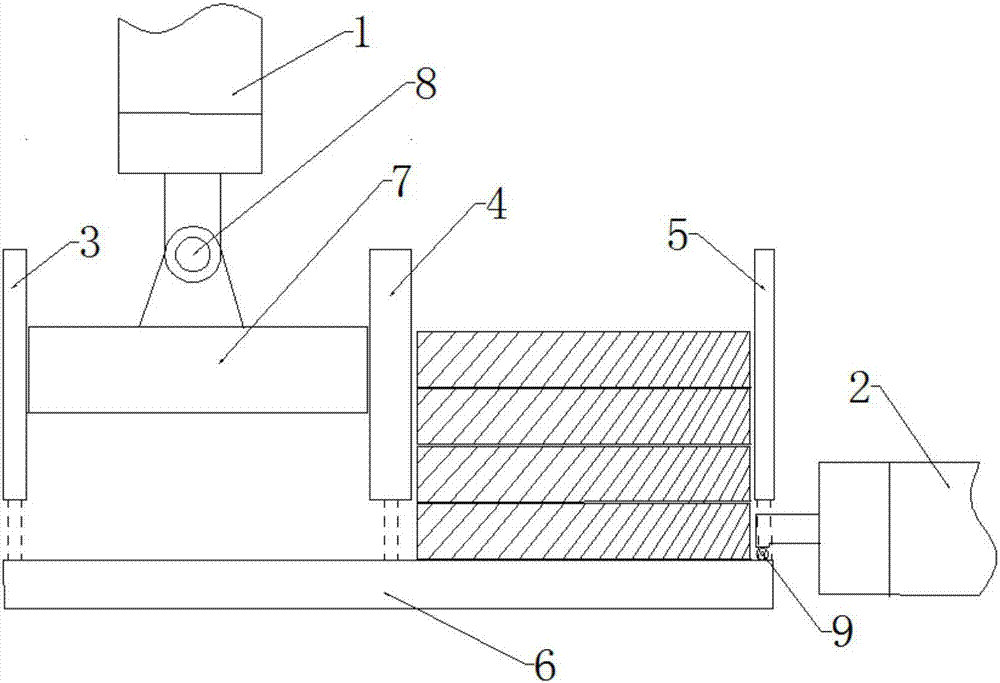

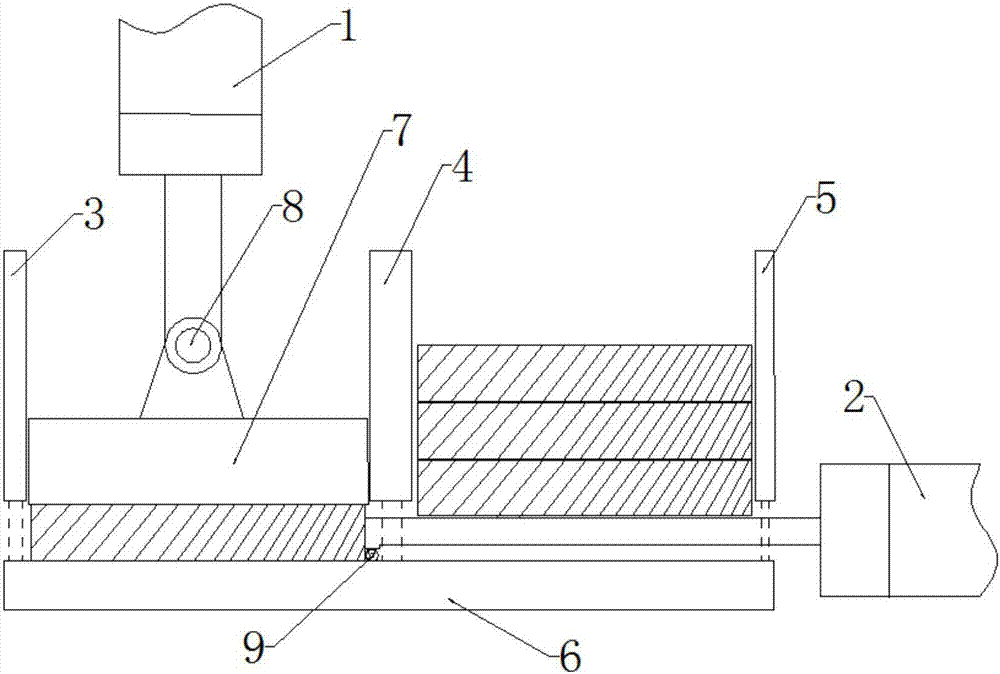

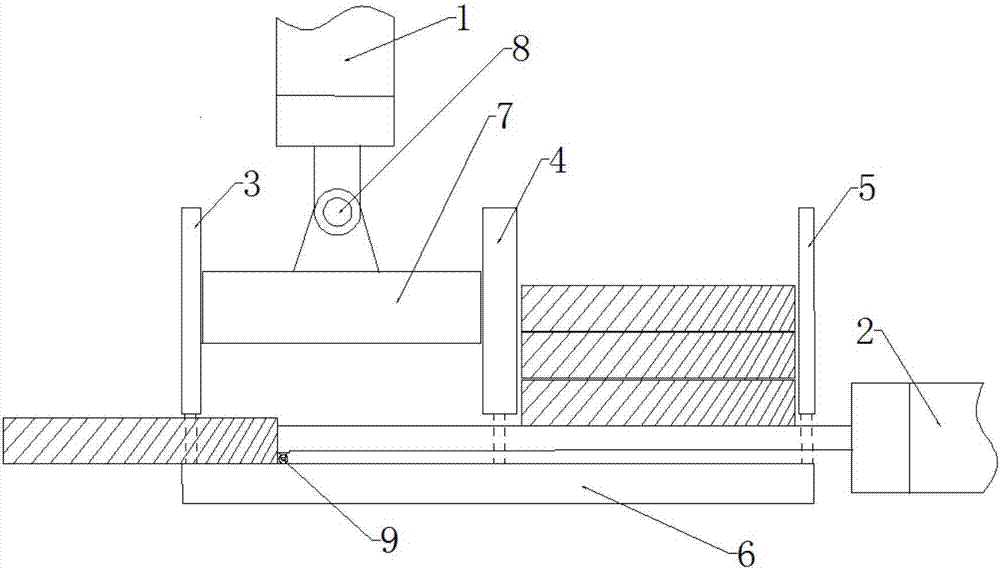

[0014] Such as figure 1 , 2 , 3, the pressing plate 7 of the present invention is connected with the hydraulic cylinder 1 through the pin shaft of the hanging plate 8, and the left end fixing plate 3 and the middle fixing plate 4 are arranged around the pressing plate 7, and the left end fixing plate 3 and the middle fixing plate 4 are respectively Fixed on the bottom support plate 6, the hydraulic cylinder 2 is placed on the left side of the bottom of the right end fixed plate 5, the right end fixed plate 5 is fixed on the bottom support plate 6, and the roller 9 is installed on the telescopic rod top of the hydraulic cylinder 2. The invention also needs a control system to drive a hydraulic cylinder, and has a simple structure and fast extrusion.

[0015] The telescopic rod of the hydraulic cylinder 2 is driven by the control system to push the aluminum alloy sheet under the platen 7, and then the telescopic rod of the hydraulic cylinder 1 is driven to drive the platen 7 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com