Glass conveyor

A conveyor and glass technology, applied to conveyor objects, transportation and packaging, furnaces, etc., can solve problems such as glass size limitations, and achieve the effect of simple structure, convenient removal of suction cups, and convenient and fast use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

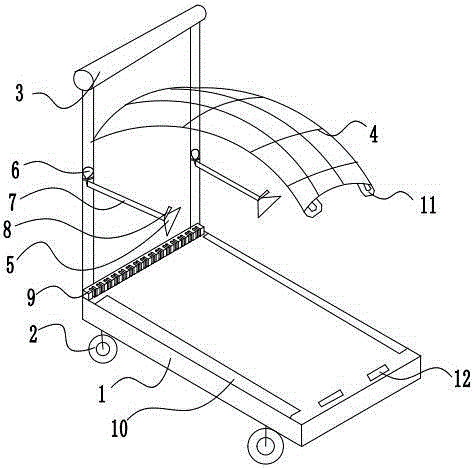

[0017] The reference signs in the drawings of the description include: bottom plate 1, pulley 2, handle 3, net cover 4, suction cup 5, air bag 6, air pipe 7, extrusion block 8, snap-in groove 9, spare handle 10, clip 11, fastener12.

[0018] Such as figure 1 The shown glass conveyor includes a bottom plate 1 of rectangular structure and four pulleys 2 connected to the bottom surface of the bottom plate 1 . Pulley 2 is a universal wheel, which is beneficial to the turning of the glass conveyor. On the top surface of the bottom plate 1, a handle 3 for pushing is connected with bolts; The top surface of the spare handle 10 in the groove and in the retracted state is lower than the top surface of the bottom plate 1; it is convenient to replace the handle 3 to pull the glass conveyor when needed, and it does not affect the glass loading and unloading when it is not in use. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com