Modified diaphragm, preparation method thereof and lithium-sulfur battery

A lithium-sulfur battery and separator technology, applied in the field of new electrochemical materials, can solve the problems of complex process, disadvantageous large-scale production, etc., and achieve the effects of simple process, large-scale production, and improvement of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a modified diaphragm for lithium-sulfur batteries, which includes a basic diaphragm and a modified layer of composite material, the modified layer of composite material is arranged on one side of the basic diaphragm, and the modified layer of composite material is The composition of the layer includes conductive agent and Cu 2 TCPP-MOF. Among them, Cu 2 TCPP-MOF has exposed N sites, which can be effectively combined with polysulfides to block it and weaken the shuttle effect of lithium-sulfur batteries; conductive agents are used to provide conductivity and promote electron transfer, and the combination of the two greatly improves The specific capacity, rate performance, Coulombic efficiency, and cycle stability of lithium-sulfur batteries were investigated.

[0029] Optionally, the basic diaphragm is a polyethylene (PE) diaphragm, a polypropylene (PP) diaphragm, a PE / PP composite single-layer diaphragm, etc., and may be one or more of them. ...

Embodiment 2

[0048] The preparation method of this example is the same as that of Example 1, except that the Cu loaded on the Celgard 2500 diaphragm 2 The mass ratio of TCPP-MOF and GO is 1:2, and other implementation conditions are the same.

[0049] Compared with Example 1, the specific capacity, cycle stability, and rate performance of the lithium-sulfur battery assembled with the modified diaphragm of this example are similar and slightly improved. Charge and discharge at 1C constant current, the initial capacity reaches 978mAh / g, the capacity is still 571mAh / g after 500 cycles, the capacity retention rate is 58%, and the rate performance is also improved accordingly.

Embodiment 3

[0051] The preparation method of this example is the same as that of Example 1, except that the Cu loaded on the Celgard 2500 diaphragm 2 The mass ratio of TCPP-MOF and GO is 1:3, and other implementation conditions are the same.

[0052] Compared with Example 1, the specific capacity, cycle stability and rate performance of the lithium-sulfur battery assembled with the modified diaphragm of this example are similar, but slightly improved. Charge and discharge at 1C constant current, the initial capacity reaches 966mAh / g, and the capacity is still 554mAh / g after 500 cycles, the capacity retention rate is 57%, and the rate performance is also improved accordingly.

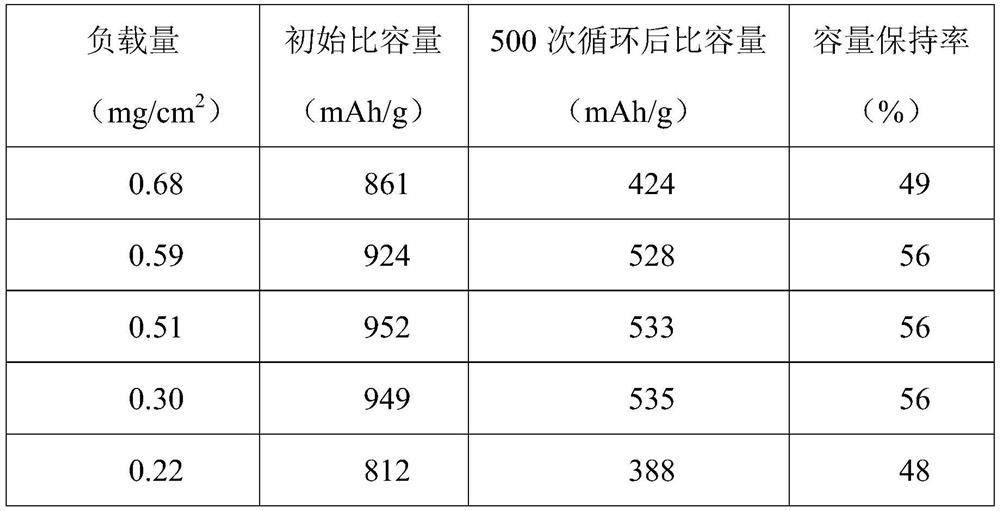

[0053] Above-mentioned embodiment 1-embodiment 3 illustrate the specific capacity of lithium-sulfur battery, cycle stability and rate performance and Cu on the base separator 2 The mass ratio of TCPP-MOF and GO is not positively correlated, but has a preferred area. The present invention has found through many expe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com