Glue sealing process for magnetic induction sunken mutual inductor

A recessed transformer technology, applied in the field of transformers, can solve problems such as easy cracking, potential safety hazards of transformers, and difficult repairs, so as to avoid cracks, reduce repair difficulties, and improve utilization rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

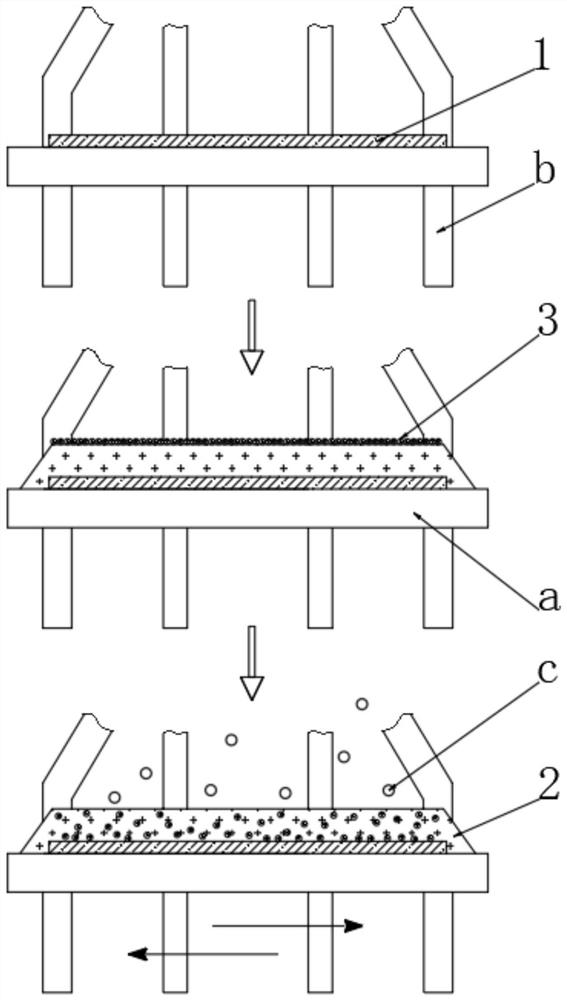

[0047] see figure 1 , in the figure, a represents the bottom plate, b represents the winding, and c represents the overflowing air bubbles. A magnetically induced internal transformer glue sealing process includes the following steps:

[0048] S1. First pour a thin layer of epoxy resin inner layer 1 on the connection between the end surface of the bottom plate and the casing and the winding, and cool and form;

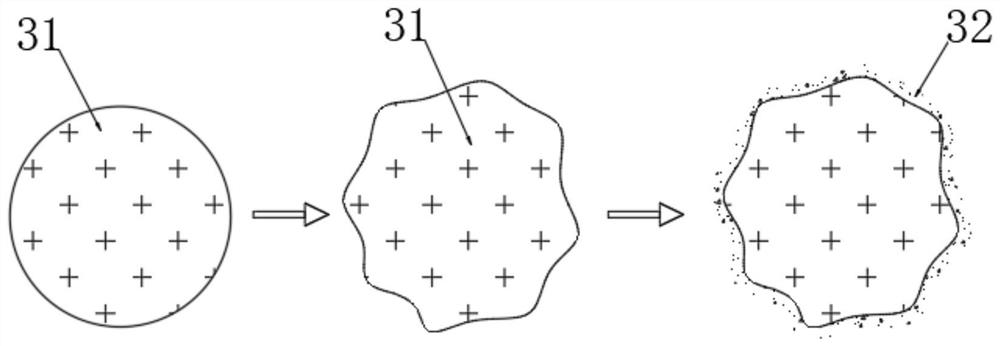

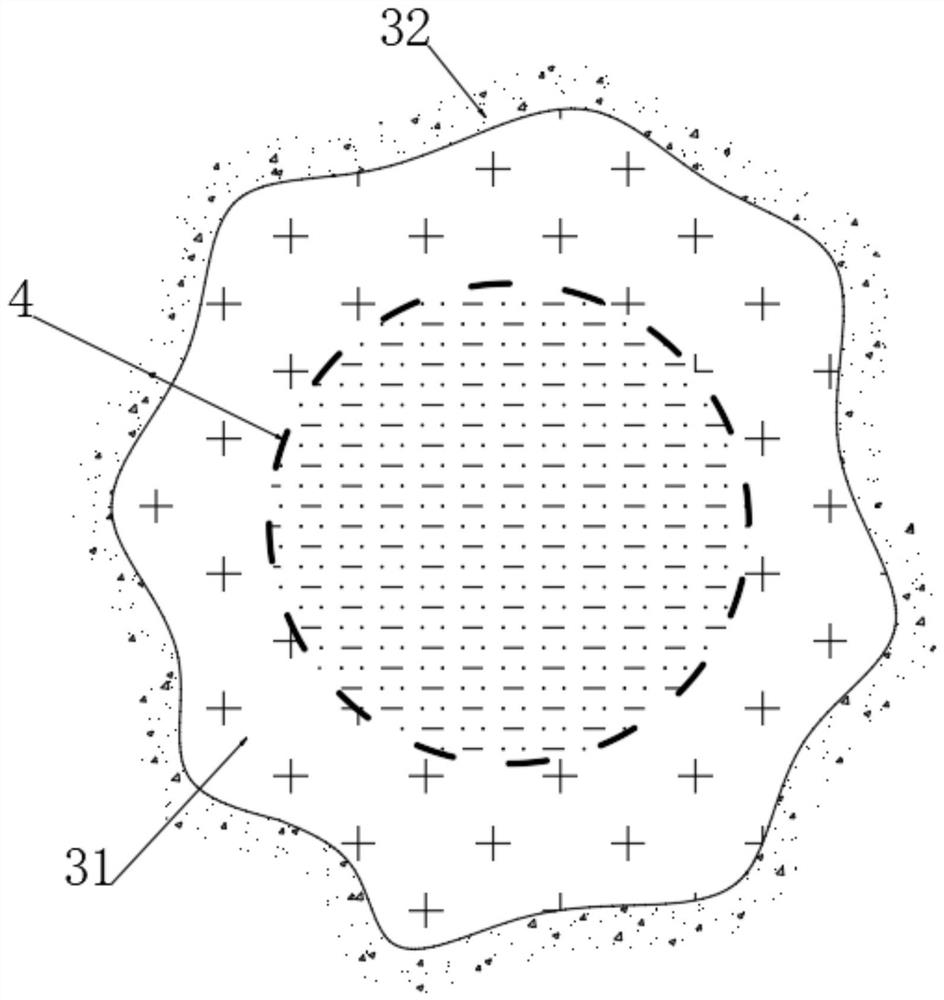

[0049] S2. First, pretreat the ABS resin ball 31 to obtain the sinking magnetic ball 3, then cast the epoxy resin outer layer 2 on the epoxy resin inner layer 1 again, and then evenly spread the sinking magnetic ball 3 on the epoxy resin on outer layer 2;

[0050] S3, then use the magnetic plate under the bottom plate to continuously reciprocate in the lateral direction, guide the sinking magnetic ball 3 to sink from the upper surface of the epoxy resin outer layer 2, and realize the longitudinal agitation of the epoxy resin outer layer 2, making it Bubbles inside ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com