Anti-cracking cutting board

A chopping board and rubber technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of easy cracks, easy food entry, cracking and damage of chopping boards, etc., to disperse stress concentration, improve the prevention of cracks, and prevent cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

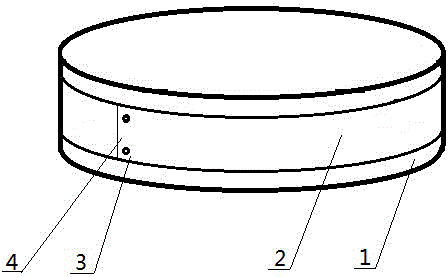

[0016] Below, combine figure 1 Examples of the present invention will be described.

[0017] A chopping board has a chopping board body 1, and a chopping board hoop is arranged on the side of the chopping board body, and the chopping board hoop is a rubber chopping board hoop 2. The rubber chopping board hoop 2 is spirally wound in multiple layers, the head and tail 4 of the rubber chopping board hoop 2 are connected to the side of the chopping board body through nails 3, and the rubber chopping board hoop 2 is overlapped and spirally wound. The sides of the cutting board body have grooved rings. The cutting board is circular in cross section. The rubber cutting board hoop 2 is made of silicon rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com