Coal sampling method and sampling vehicle

A technology for sampling vehicles and coal samples, applied in the direction of sampling devices, etc., can solve the problems of many artificial interference factors, low precision, sampling distortion, etc., and achieve the goal of avoiding artificial interference factors, realizing back-checking and deviation correction, and reducing sampling deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

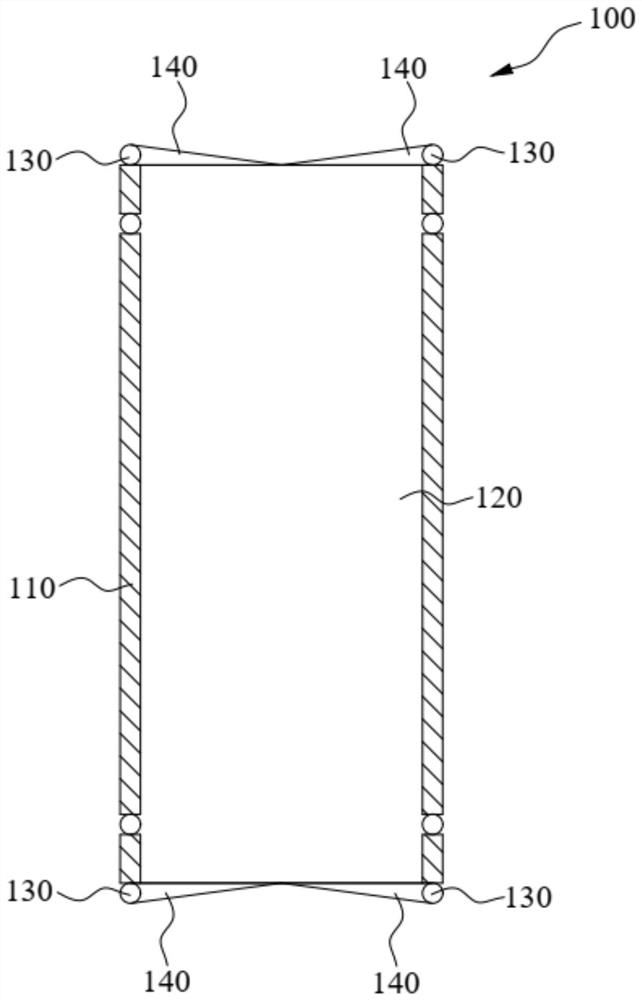

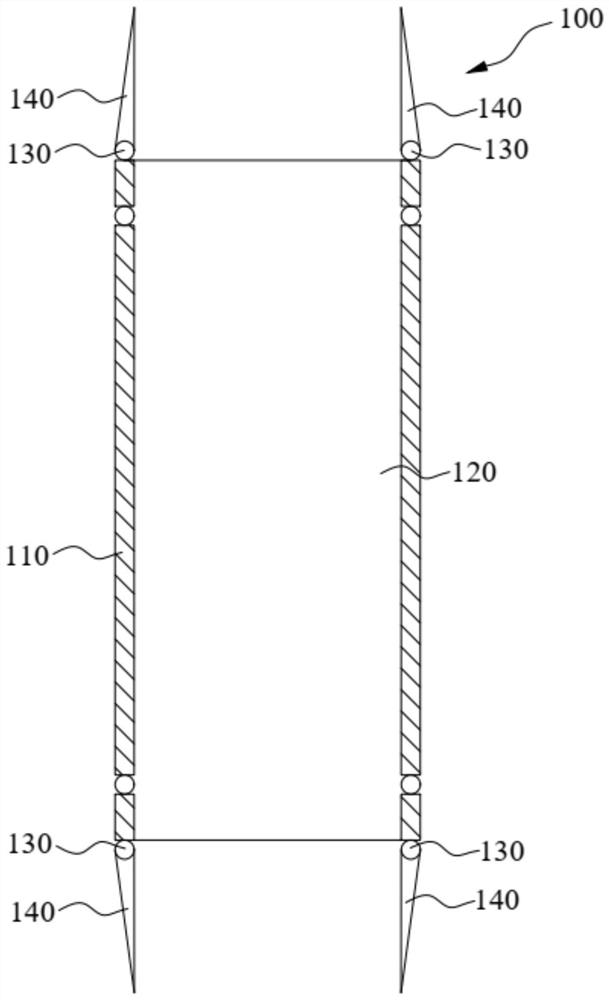

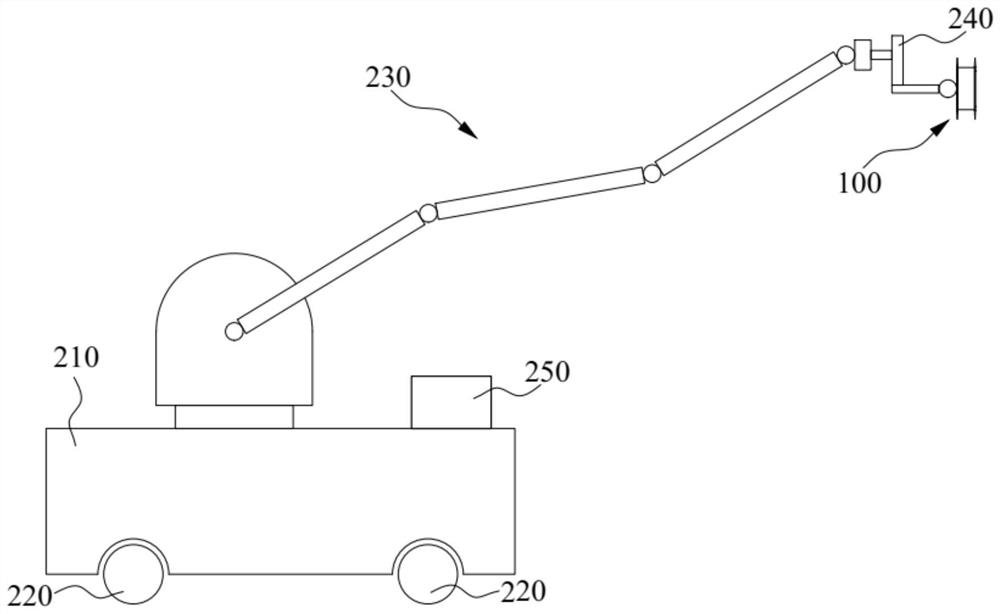

[0059] like figure 1 As shown, the present invention provides a sample head 100 for taking a coal sample, the sample head 100 includes a sample tube 110, and both ends of the sampling tube 110 rotate with multiple bass 140, when the sample head is in the first In the state, the baht 140 encloses both ends of the sampling tube 110 to enclose the plurality of impartial tabs 140 to the sample tube 110 into a sample chamber 120, and the sample cavity 120 is used to collect coal samples, and both ends of the sample cavity 120 are in the external environment. Connect. With both ends of the two ends, the sampled head 100 can cause the sampling head 100 to enter the sample cavity 120, and thereby avoiding the case of mixing the surface of the surface coal in the sample cavity 120 to avoid sampling accuracy. The sampled head 100 can be achieved by using the onset 140 to open or close the sample cavity 120, and the sample head 100 can be achieved in a predetermined sampling position to be t...

Embodiment 2

[0072] like Figure 4 As shown, the present invention also provides another sampled head 100 for adopting a coal sample, and the sample head 100 includes an inner cylinder 150 and an outer cylinder 160 in the inner cylinder 150, and the inner cylinder 150 is convex The tapered member 153 is provided, and the outer cylinder 160 is rotated to the inner cylinder 150, and the inner cylinder 150 is provided with inner cylindrical cavity 151 for collecting the coal sample, and the inner cylinder 150 is opened in the inner cylinder of inner cylindrical cavity 151. The body hole 152, the outer cylinder 160 is opened, and when the outer cylinder hole 161 communicates with the inner cylinder hole 152, the inner cylindrical cavity 151 is opened / closed. The outer cylinder hole 161 can communicate / partition the outer cylinder hole 161 and the inner cylinder hole 152 by the inner cylinder 150 and the outer cylinder 160, thereby opening / closing the inner cylindrical cavity 151, the above-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com