Cast-in-place continuous box girder construction system and construction technology

A box girder construction and cast-in-situ technology, which is applied to bridges, bridge materials, bridge construction, etc., can solve the problems that cast-in-situ continuous box girder cannot be formed, affect cast-in-situ continuous box girder, poor forming effect, etc. High torsional stiffness and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is attached Figure 1-6 The application is described in further detail.

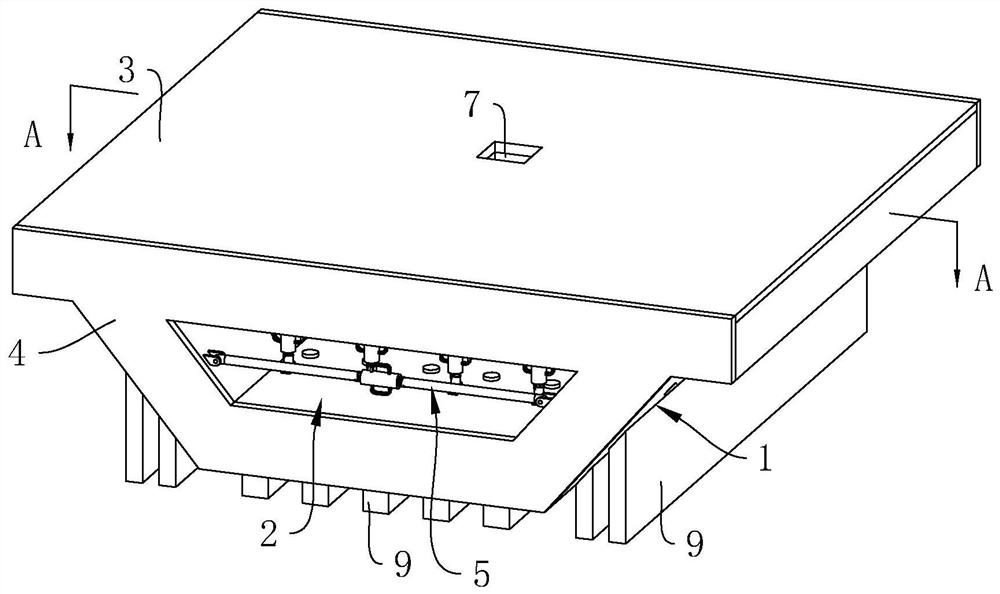

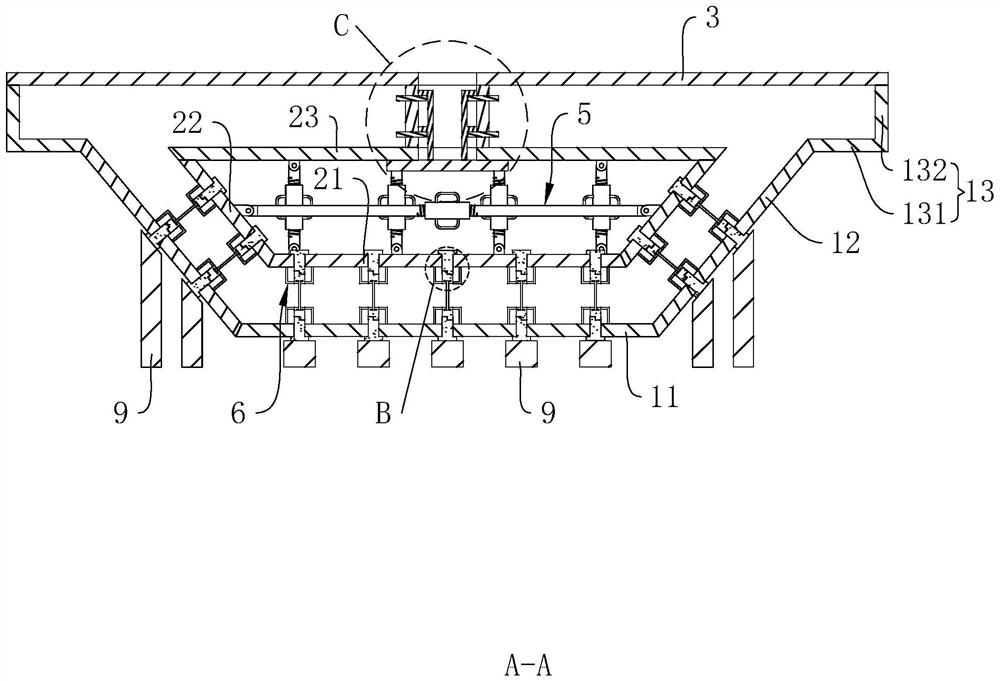

[0051] The embodiment of the application discloses a cast-in-place continuous box girder construction system. refer to figure 1 and figure 2 , The cast-in-place continuous box girder construction system includes formwork devices.

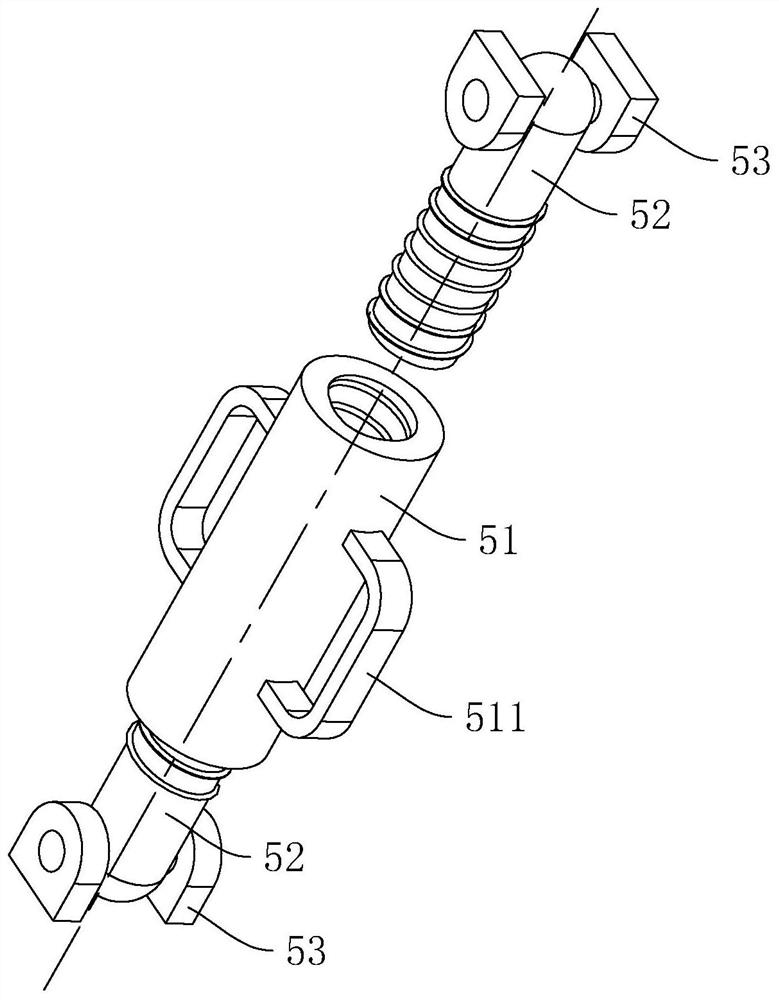

[0052] The template device includes an outer mold 1 , an inner mold 2 , a top mold 3 and an end mold 4 . The outer mold 1, the inner mold 2, the top mold 3 and the end mold 4 can all use Visa formwork, the outer mold 1 includes a bottom mold 11, a side mold 12 and a flange formwork 13, the bottom mold 11 is a rectangular plate, and the side mold 12 is inclined It is arranged on both sides of the bottom mold 11 in the width direction; the side mold 12 and the bottom mold 11 enclose to form a tank with an inverted isosceles trapezoidal cross section. Flange formwork 13 is arranged on the end of side formwork 12 away from bottom formwork 11, and the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com