Novel anti-cracking asphalt concrete pavement structure and construction method

A technology of asphalt concrete and pavement structure, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve problems such as pavement structure damage and road use function decline, achieve long service life, convenient transportation and construction, stable Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

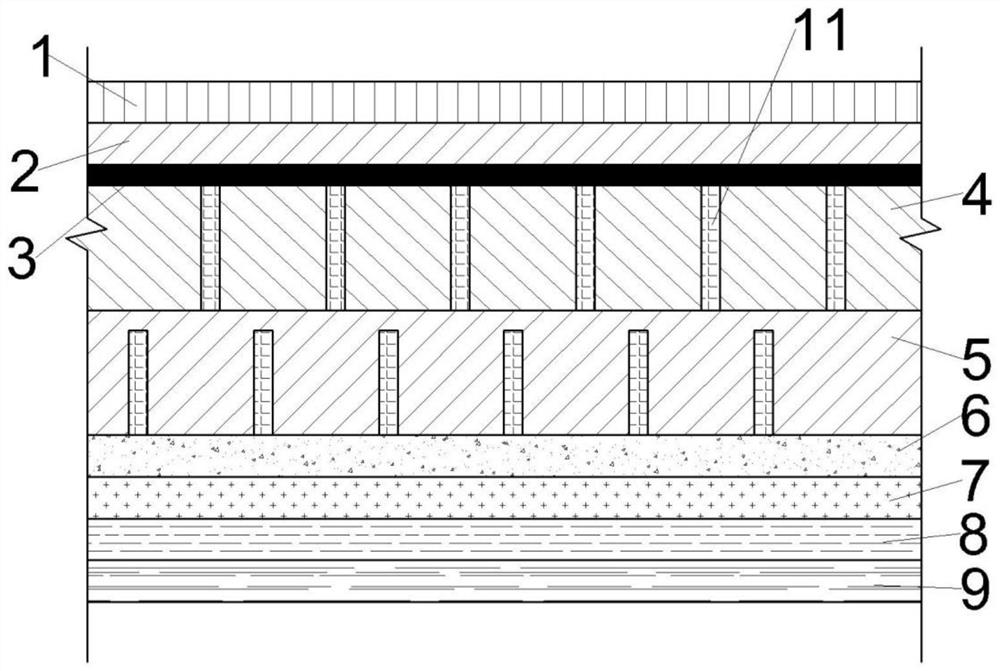

[0034] refer to Figure 1-5 As shown, the present embodiment provides a novel anti-cracking asphalt concrete pavement structure, including a surface course, a base course and a cushion course laid from top to bottom; 6. A glass fiber cloth 3 is laid between the upper base 4 and the surface layer, and a geocell 11 is arranged inside the upper base 4 and the lower base 5;

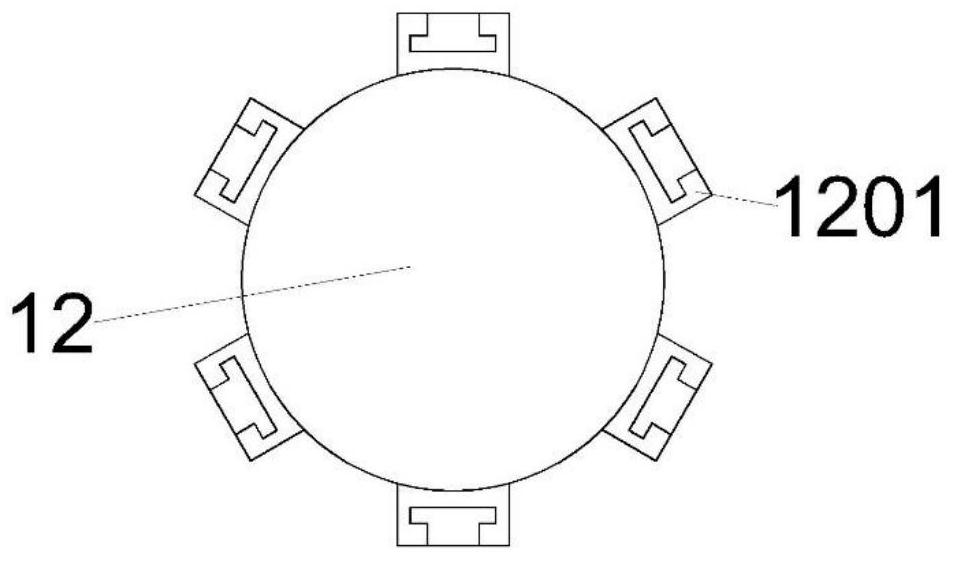

[0035] Geocell 11 is a triangular structure in top view, and the vertices of adjacent triangular structures coincide. Geocell 11 includes several geogrids 10 , and locking pins 12 are detachably connected to opposite sides of geogrid 10 .

[0036] In the present invention, a geocell 11 is arranged inside the upper base 4 and the lower base 5 and the geocell 11 is arranged in a triangular structure, and the stability of the triangular structure is used to improve the stability of the geocell 11, and the geocell 11 makes the upper The materials in the base layer 4 and the lower base layer 5 are divided into mu...

Embodiment 2

[0053] refer to Image 6 As shown, the difference between the anti-cracking asphalt concrete pavement structure of this embodiment and the first embodiment is that the geocells 11 of the upper base 4 and the geocells 11 of the lower base 5 are arranged alternately, and the outer wall of the locking pin 12 is provided with Several anti-off grooves 1202, the lower end of the snap-in groove does not pass through the lower end of the snap-in block 1201. After the upper base layer 4 and the lower base layer 5 are compacted, the snap-in pin 12 is placed between the upper base layer 4 and the lower base layer under the action of the anti-off groove 1202. The vertical position in the base layer 5 is more stable. When the upper base layer 4 and the lower base layer 5 are pressed down by the vehicle on the road, the locking pin 12 provides an upward force for the geogrid 10, so that the geocell 11 is the upper The base layer 4 and the lower base layer 5 provide a flexible resistance, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com