A kind of alginic acid-chitooligosaccharide-zinc oxide composite hydrogel and its preparation method and application

A composite hydrogel and chitosan oligosaccharide technology, which can be used in pharmaceutical formulations, bandages, drug delivery, etc., can solve the problems of low antibacterial activity, improvement of wound healing effect, poor mechanical properties and biocompatibility, and achieve good results. Wound repairing effect, overcoming weak mechanical properties, and strong broad-spectrum antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

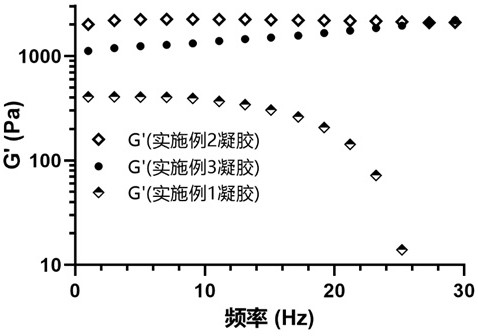

Embodiment 1

[0046] A preparation method of alginic acid-chitooligosaccharide hydrogel is as follows: Weigh 20 g of alginic acid (viscosity 10 mPa s) and disperse it in 75 mL of ethanol, then slowly drop into the reaction mixture 100 g of periodate containing 2.7 g mL of aqueous solution was stirred at room temperature and protected from light for 48 h. After the reaction was completed, ethylene glycol was added to continue stirring for 0.5 h to terminate the reaction. After precipitation with 4 volumes of 95% ethanol, dialysis and freeze-drying, oxidized alginic acid was obtained. Mix 0.5 mL of 200 mg / mL oxidized alginic acid solution with 0.5 mL of 150 mg / mL chitosan oligosaccharide (3 kDa) solution, stir and mix well to obtain alginic acid-chitooligosaccharide hydrogel.

[0047] The hydrogel includes the following components in mass percentage: 20% oxidized alginic acid, 15% chitosan oligosaccharide, and the balance is water.

Embodiment 2

[0049] A preparation method of alginic acid-chitooligosaccharide-zinc oxide composite hydrogel is as follows: Weigh 20 g of alginic acid (viscosity 50 mPa s) and disperse it in 75 mL of ethanol, and then slowly drop into the dispersion system 10.8 g of acid in 100 mL of aqueous solution was stirred at room temperature and protected from light for 24 h. After the reaction was completed, ethylene glycol was added and stirred for 1 h to terminate the reaction. After precipitation with 4 volumes of 95% ethanol, dialysis and freeze-drying, oxidized alginic acid was obtained. Drop 0.1 mol / L sodium hydroxide solution (solvent is methanol) into 0.1 mol / L zinc acetate solution (solvent is methanol), stir continuously for 4 h, remove by-products by centrifugation and washing, and calcinate the precipitate at above 300°C, Zinc oxide nanoparticles are obtained. Disperse 500 μg of zinc oxide nanoparticles in 0.5 mL of 100 mg / mL oxidized alginic acid solution to obtain a solution with a co...

Embodiment 3

[0052] A preparation method of alginic acid-chitooligosaccharide-zinc oxide composite hydrogel is as follows: Weigh 20 g of alginic acid (viscosity 80 mPa s) and disperse it in 75 mL of ethanol, and then slowly drop into the dispersion system 21.6 g of potassium potassium chloride in 100 mL of aqueous solution was stirred at room temperature and protected from light for 2 h. After the reaction was completed, ethylene glycol was added to continue stirring for 3 h to terminate the reaction. After precipitation with 4 volumes of 95% ethanol, dialysis and freeze-drying, oxidized alginic acid was obtained. Drop 0.1 mol / L ammonium hydroxide solution (solvent is methanol) into 0.1 mol / L zinc sulfate solution (solvent is methanol), stir continuously for 6 h, remove by-products by centrifugation and washing, and deposit the precipitate at 300°C or higher calcined in a furnace to obtain zinc oxide nanoparticles. Disperse 250 μg of zinc oxide nanoparticles in 0.5 mL of 100 mg / mL oxidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com