Novel grouting agent

A new type of coagulant technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unreasonable use of admixtures, insufficient effect, difficult control of the expansion process, etc., to achieve enhanced stability , Improve the expansion effect and control the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

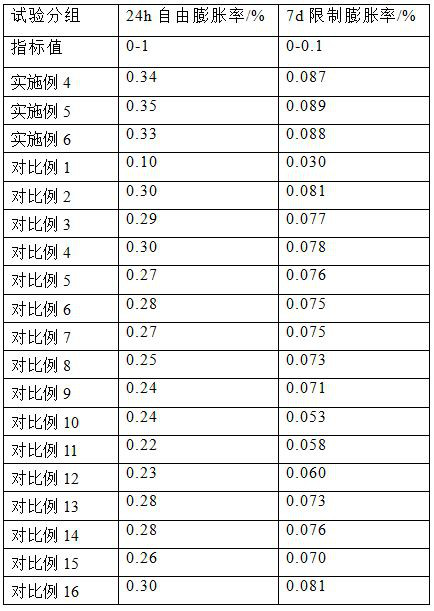

Examples

Embodiment 1

[0035] This embodiment provides a new type of grouting agent, including 10 parts of expansion-water-reducing compound, 15 parts of expansion-retarding component and 5 parts of retarder B. The expansion component in the expansion-water-reducing compound is expansion agent A, the expansion-retarder component includes expansion agent B and retarder A.

[0036] Expansion agent A is composed of sulfoaluminate type expansion agent and calcium oxide type expansion agent according to the mass ratio of 1:1, the mass ratio of expansion agent B and retarder A is 1:0.8, and expansion agent B is calcium oxide type expansion agent , the retarder A is molasses, and the retarder B is citric acid.

Embodiment 2

[0038] On the basis of Example 1, this example also provides a new type of grouting agent. The raw materials for the preparation of the expansion-water-reducing compound include: 30 parts of acrylic acid, 10 parts of sodium methacrylate, allyl alcohol poly 8 parts of oxyethylene ether, 0.14 parts of initiator, 0.1 part of fumed silica, 20 parts of expansion agent A, and the initiator is azobicyclohexylcarbonitrile.

[0039] The preparation method of swelling-water-reducing compound is:

[0040] S1. Dry the reaction raw materials acrylic acid, sodium methacrylsulfonate, allyl alcohol polyoxyethylene ether, initiator, fumed silica, and expansion agent A to remove moisture respectively, and set aside;

[0041] S2. Add allyl alcohol polyoxyethylene ether into the reaction vessel, heat to dissolve, then add sodium methacrylate and fumed silica, and stir at 200r / min for 10min to obtain a suspension;

[0042] S3. After mixing the acrylic acid and 1 / 2 initiator evenly, add dropwise to ...

Embodiment 3

[0048] On the basis of Example 1, this embodiment also provides a novel grouting agent, the preparation method of the expansion-retarding component is:

[0049] A. After the expansion agent B is dried, mix it evenly, place it in a pulverizer of 1000r / min, pulverize it, pass through a 160 mesh sieve, and obtain the expansion agent B powder;

[0050] B. After heating and melting retarder A, add expansion agent B powder and mix evenly, then pass through a granulator to make 80-mesh granules, and then put them into a spherical shot blasting machine to make a ball core;

[0051] C. Put the ball core into the coating machine, spray into the coating material liquid, cool and dry to obtain the expansion-retarding component.

[0052] The mass ratio of pellet core to coating material solution is 1:0.02.

[0053] The preparation method of the coating material liquid is as follows: the paraffin, palm oil and o-phenylphenol glycidyl ether are dried to remove water respectively, and set as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com