Automatic cutting machining machine and method for tempered glass

A technology for cutting and tempering glass, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of increasing the labor intensity of operators, reducing friction, and reducing the utilization rate of cutting devices, so as to improve wear resistance and Cutting quality, reduction of grinding force and frictional heat, fast and accurate cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

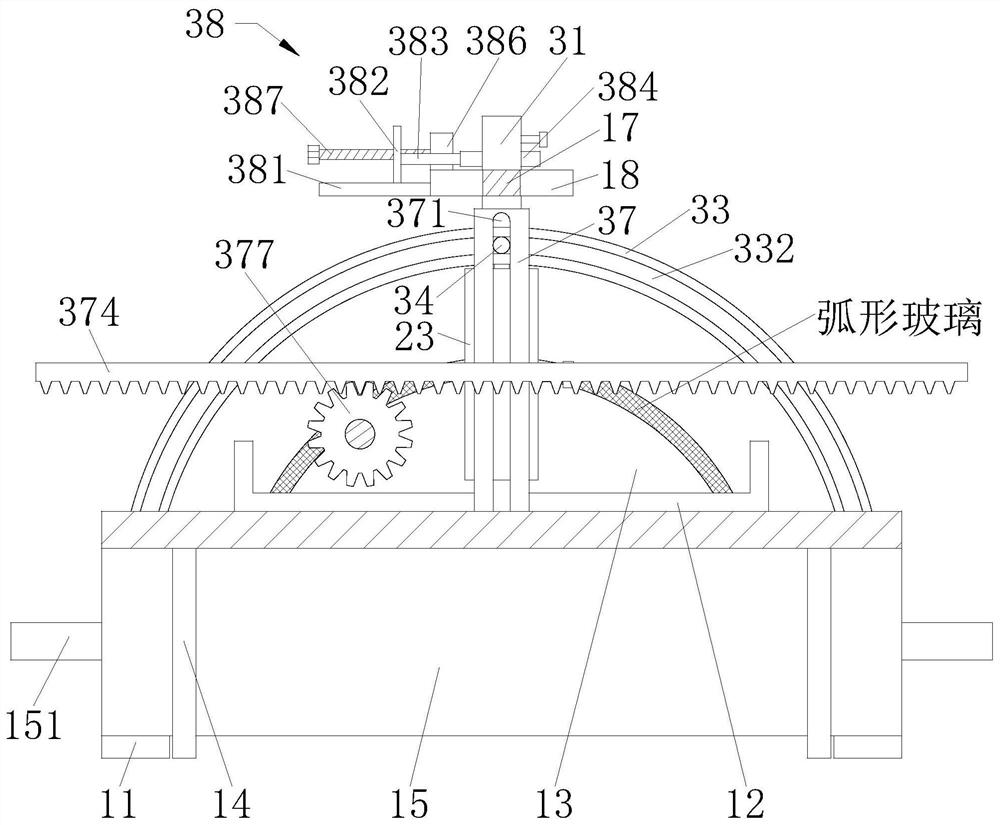

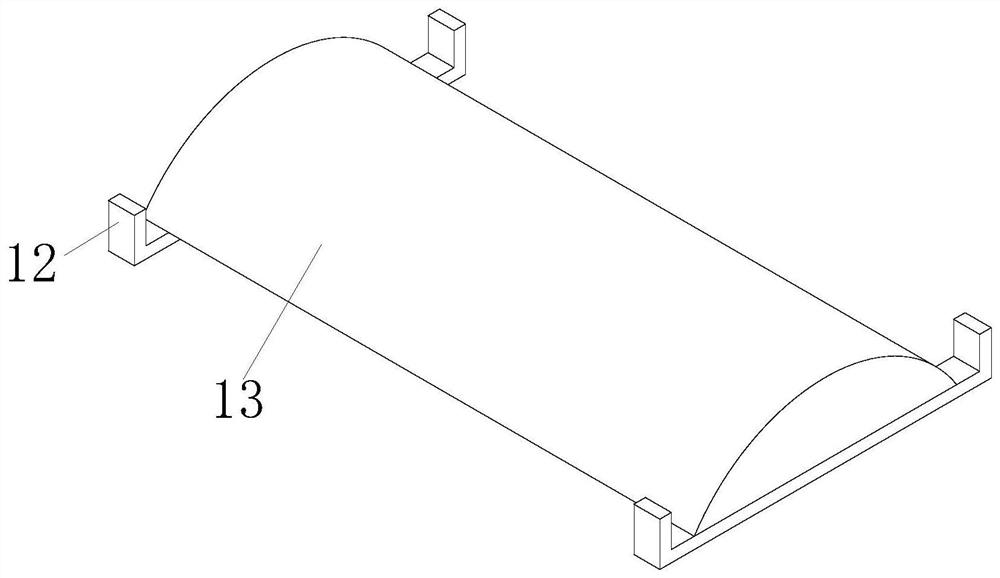

[0037] like Figure 1 to Figure 9 As shown, an automatic cutting and processing machine for tempered glass includes a workbench 10 and a support leg 11 arranged at the bottom corner of the vertical section of the workbench 10. There is a T-shaped slot 101, the left end of the T-shaped slot 101 is an inverted T-shaped structure, the T-shaped slot 101 extends along the length direction of the workbench 10, and the top of one group of vertical sections of the workbench 10 is provided with a moving groove 102, The front end of the moving slot 102 is an inverted T-shaped structure, and the moving slot 102 extends along the width direction of the vertical section of the worktable 10, and the moving slot 102 is not in contact with the T-shaped slot 101, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com