Quasi-temperature isostatic pressing forming method and die

A technology of warm isostatic pressing and forming molds, applied in molds, ceramic molding machines, mold auxiliary parts, etc., can solve problems affecting sample molding quality, mold damage, etc., to avoid internal stress, avoid temperature gradients, and good air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082] The quasi-thermal isostatic pressing molding of 3D self-sealing layered CNT paper / resin-based composite material (see patent 201910114419.2 for the preparation technology of the composite material preform sample) is taken as an example to illustrate the assembly and use of the mold.

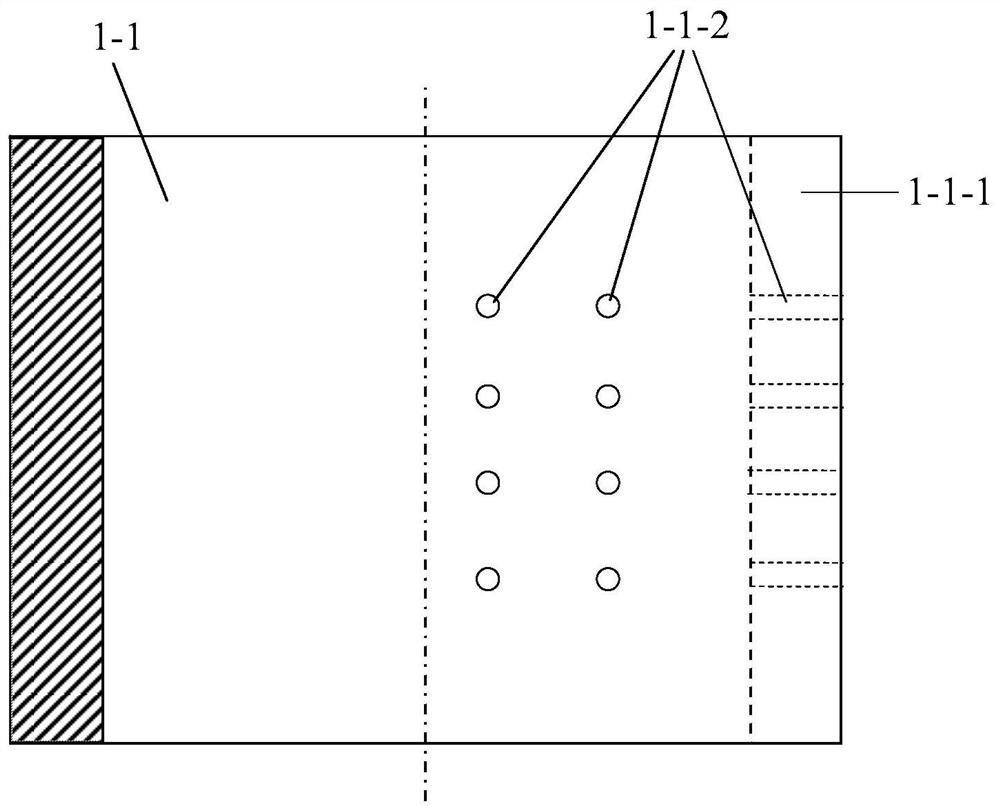

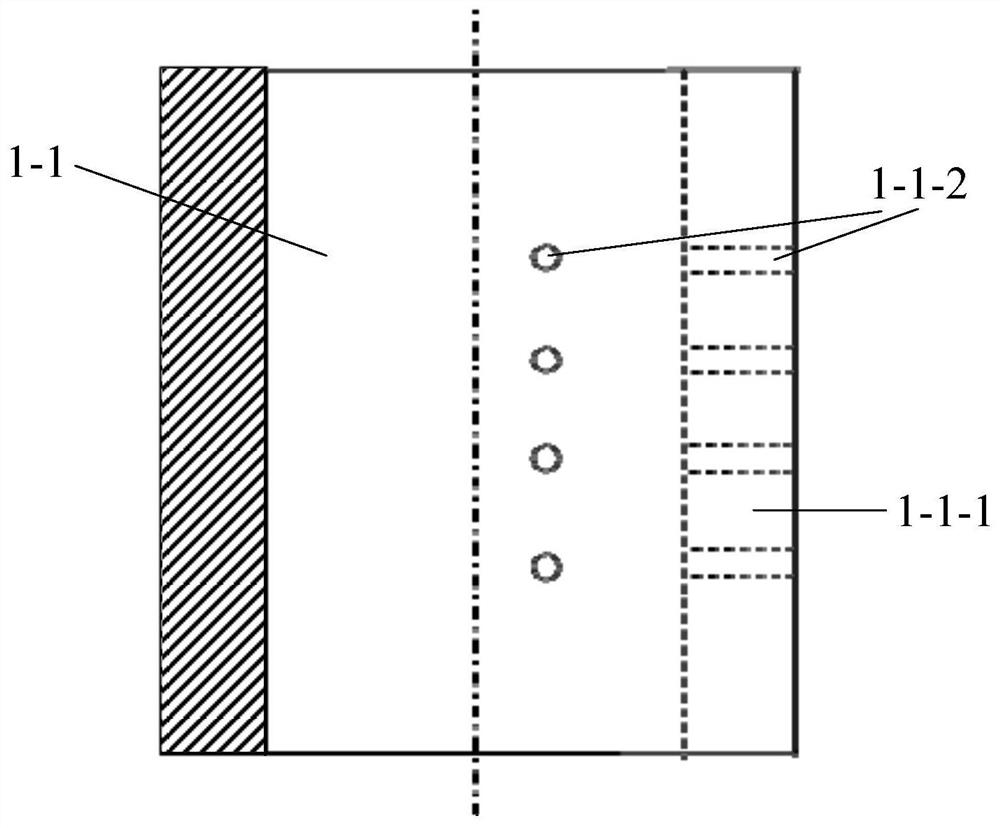

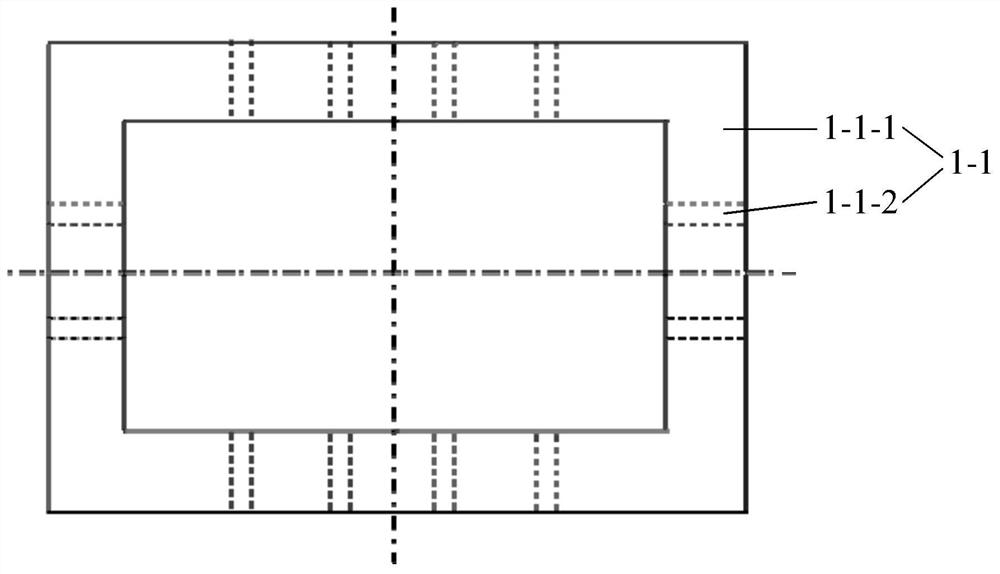

[0083] (1) Assembly mold

[0084] to combine Figure 1a-1e as well as Figure 2a-2f , first assemble the mold. The lower layer of the inner mold 2 is packed into the cavity of the female mold from the lower surface of the female mold 1-1 of the outer mold 1. In addition to the central silica gel in the lower layer of silica gel, a first compensation layer 3-1 with the same area as the upper surface of the remaining 4 silica gels (such as Figure 2c and 2d ). Then put the middle layer of the inner mold 2 into it, the middle layer is divided into 9 pieces, the central piece of silica gel is taken out, and 4 pieces of the remaining 8 pieces of silica gel are in contact with the first cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com