Laboratory automatic logistics system robot

A logistics system and mobile robot technology, applied in the field of laboratory automatic logistics system robots, can solve the problems of exposure to chemicals, high labor intensity, and high error rate, and achieve the effects of reducing contact, saving personnel costs, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

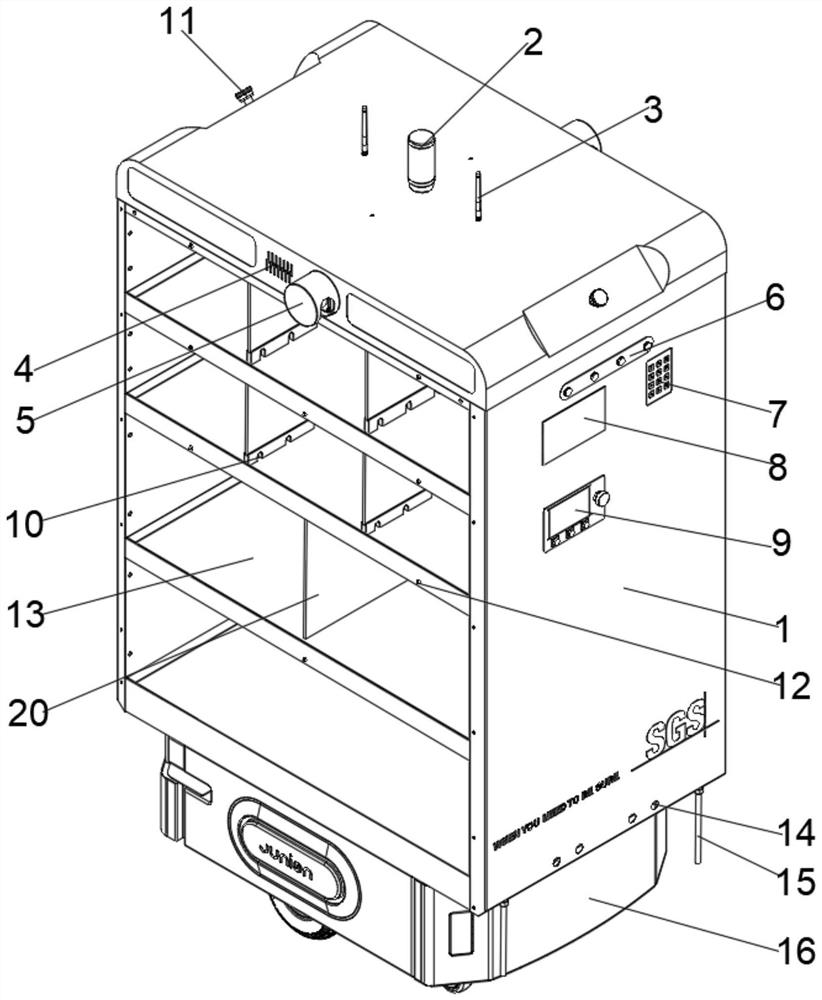

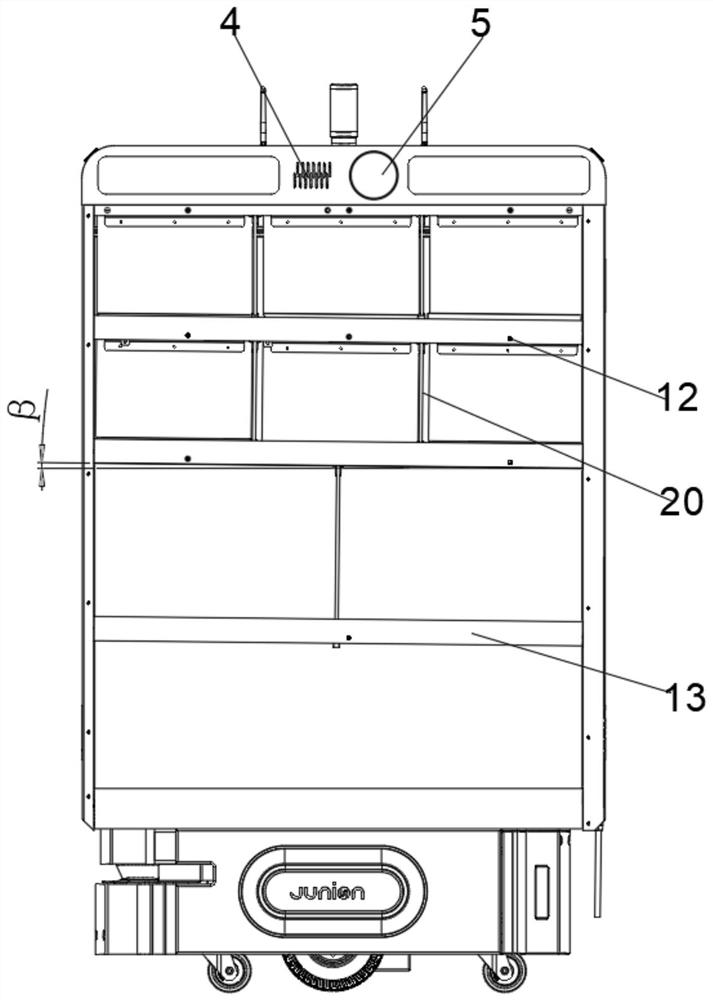

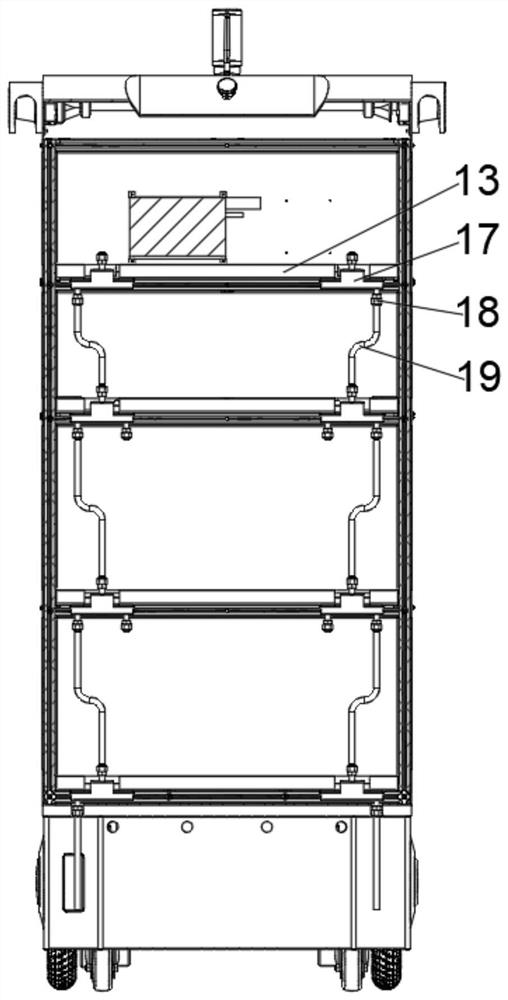

[0049] Such as Figure 1-8 As shown, the embodiment of the present invention provides a laboratory automatic logistics system robot, including a loading platform 1 and a mobile robot body 16, the mobile robot body 16 is a high-load AGV trolley, and the mobile robot body 16 is provided with a front main laser for controlling The front path is identified, the object stage 1 is fixedly arranged on the upper end of the mobile robot body 16, the rear side wall of the object stage 1 is provided with an industrial flat panel 8, a control panel 9 and a numeric keypad 7 near the upper end, and the control panel 9 is provided with a robot The switch button, the display screen on the panel can display information such as the current robot task, target point and fault, the industrial tablet 8 and the numeric keypad 7 are located on the same level, and are fixed on the side wall of the stage 1 at the upper end of the industrial tablet 8 and the numeric keypad 7 There are independent button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com