Preparation method and application of graphene reinforced AlSi10Mg nanocomposite

A nanocomposite material and graphene technology, applied in the field of graphene-enhanced AlSi10Mg nanocomposite material preparation, can solve problems such as inability to meet the mechanical properties of parts, achieve high interface bonding and wettability, uniform distribution of graphene, and avoid agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

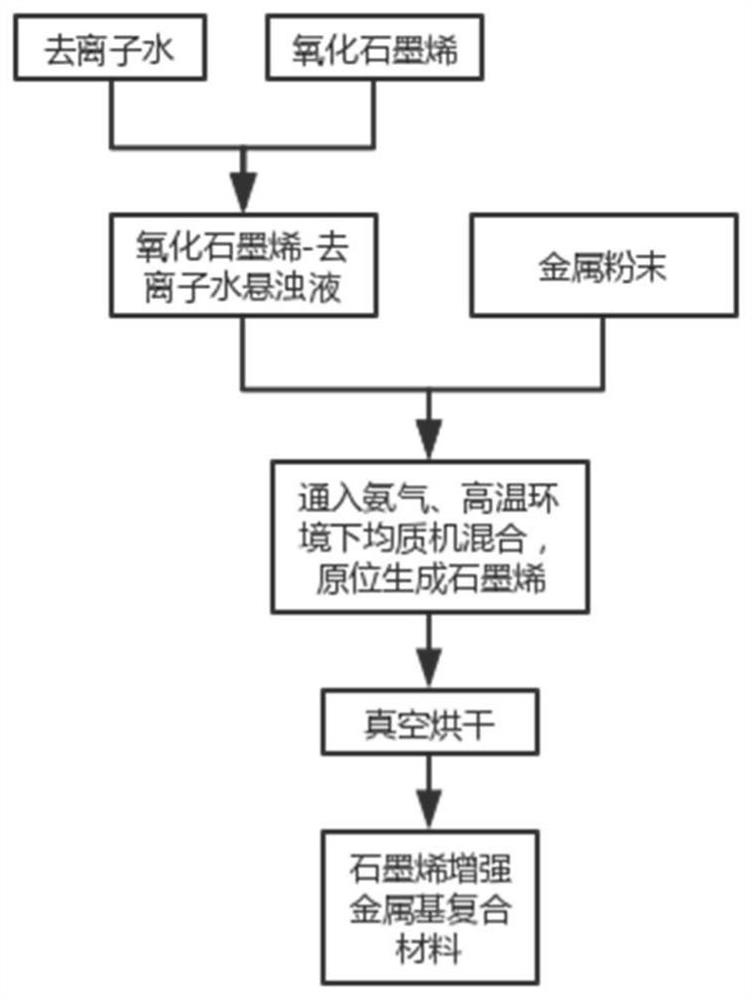

[0030] A kind of graphene reinforced AlSi10Mg nano composite material preparation method, comprises the following steps:

[0031] S1, preparation of graphene oxide-deionized water suspension:

[0032] Mix the graphene oxide powder and deionized water evenly to obtain suspension A;

[0033] Specifically, the graphene oxide powder and deionized water are uniformly mixed by an ultrasonic vibration method to obtain a graphene oxide-deionized water suspension;

[0034] Among them, the number of film layers of graphene oxide powder is 1-2 layers, the particle size is 0.2-5nm, and the purity is 99.9%, such as figure 2 and image 3 As shown; the mass of graphene oxide powder and the volume ratio of deionized water are (1-20mg): 1ml, and the time of ultrasonic vibration is not less than 2h.

[0035] S2, mixing the suspension A and the AlSi10Mg powder uniformly under an ammonia atmosphere at a mixing temperature of 500-800° C., and then drying in a vacuum environment to obtain a gra...

Embodiment 1

[0042] (1) Take AlSi10Mg powder as the matrix powder, with a particle size of 15-53 μm. The mass of graphene oxide powder and the volume ratio of deionized water are 5mg:1ml, and the mass of graphene oxide in the graphene oxide-deionized water suspension is 0.3% of the mass of AlSi10Mg powder. Weigh 3g of graphene oxide and measure 600ml of deionized water. Sonicate and mix for 2h.

[0043] (2) Add 997g of AlSi10Mg powder and graphene oxide-deionized water suspension into the homogenizer. Set the revolution speed of the homogenizer to 20r / min, the autopropagation speed to 1000r / min, the flow rate of ammonia gas to 100ml / min, and the temperature to 500°C. Mixed reaction 5min, obtains mixture A.

[0044] (3) The mixture A was dried in vacuum for 12 hours, the drying temperature was set at 110°C, and the graphene-reinforced AlSi10Mg nanocomposite was obtained by drying.

[0045] (4) Use the laser selective melting technology to print samples with the powder, and carry out mecha...

Embodiment 2

[0048] (1) Take AlSi10Mg powder as the matrix powder, with a particle size of 15-53 μm. Take the mass of graphene oxide powder and the volume ratio of deionized water as 10mg:1ml, and the mass of graphene oxide in the graphene oxide-deionized water suspension is 0.6% of the mass of AlSi10Mg powder. Weigh 6g of graphene oxide and measure 600ml of deionized water. Sonicate and mix for 2h.

[0049] (2) Add 994g of AlSi10Mg powder and graphene oxide-deionized water suspension into the homogenizer together. Set the revolution speed of the homogenizer to 20r / min, the autopropagation speed to 1000r / min, the flow rate of ammonia gas to 100ml / min, and the temperature to 500°C. Mixed reaction 5min, obtains mixture A.

[0050] (3) The mixture A was dried in vacuum for 12 hours, the drying temperature was set at 110°C, and the graphene-reinforced AlSi10Mg nanocomposite was obtained by drying.

[0051] (4) Use the laser selective melting technology to print samples with the powder, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com