Rice mill

A technology of rice milling machine and rice milling roller, which is applied in the field of rice milling machines, can solve the problems that broken rice cannot be effectively solved, the amount of feeding can not be controlled, and the equipment occupies a large area, so as to ensure the effect of rice milling and retain The effect of rice nutrition and compact structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

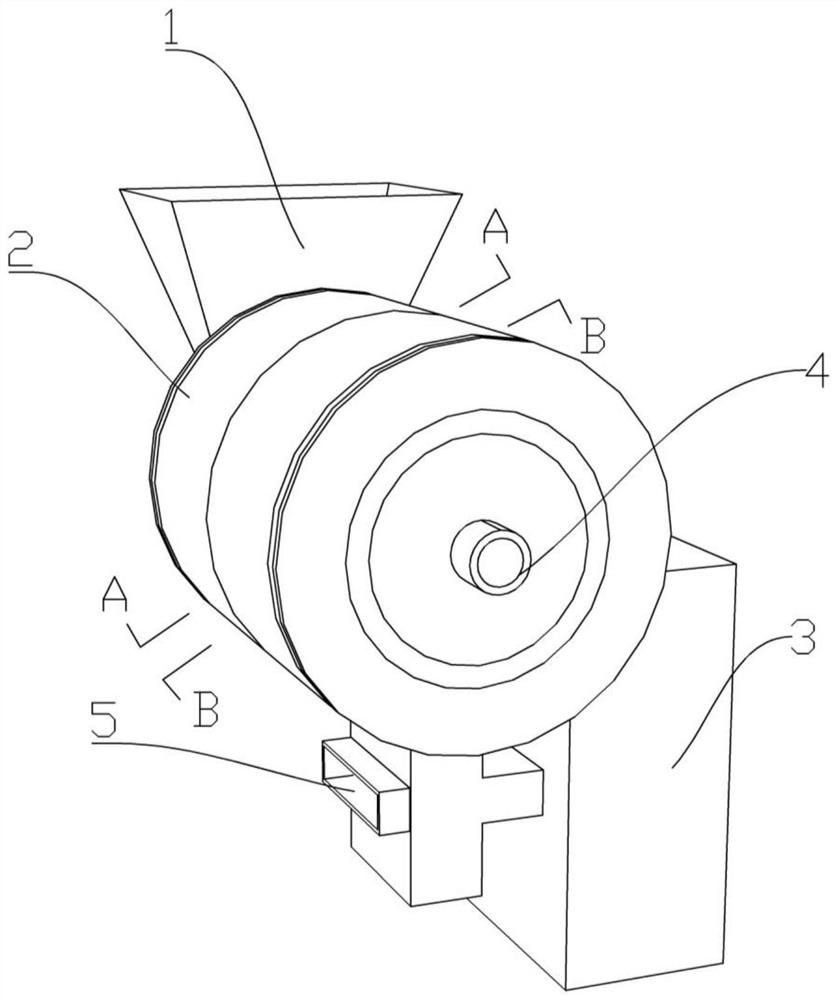

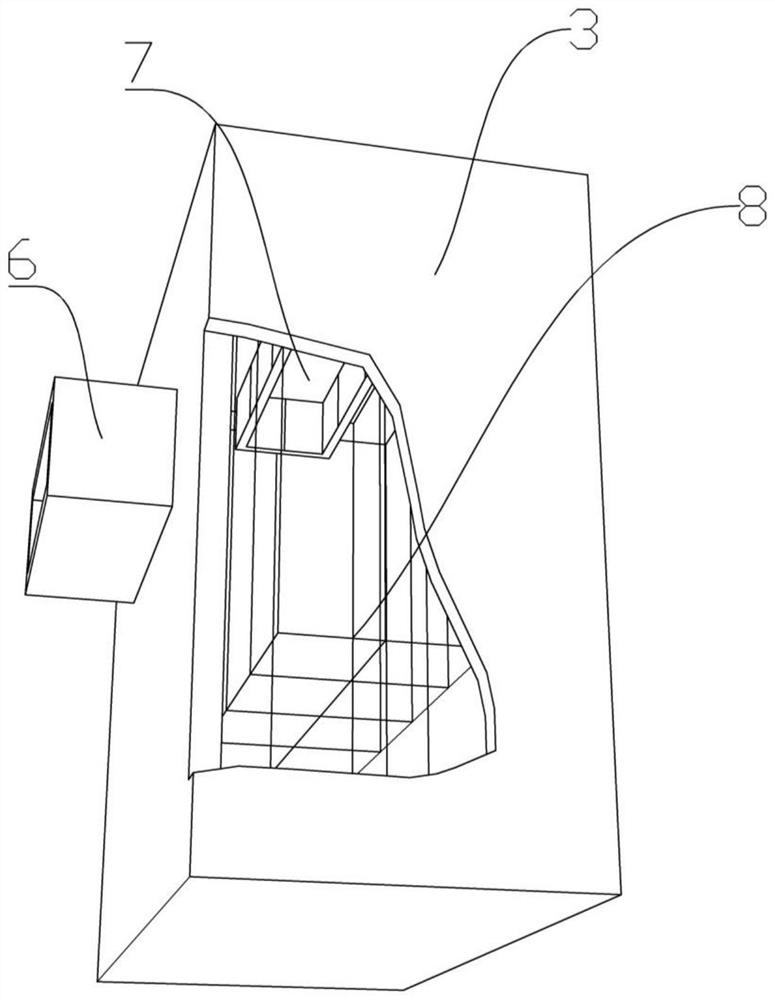

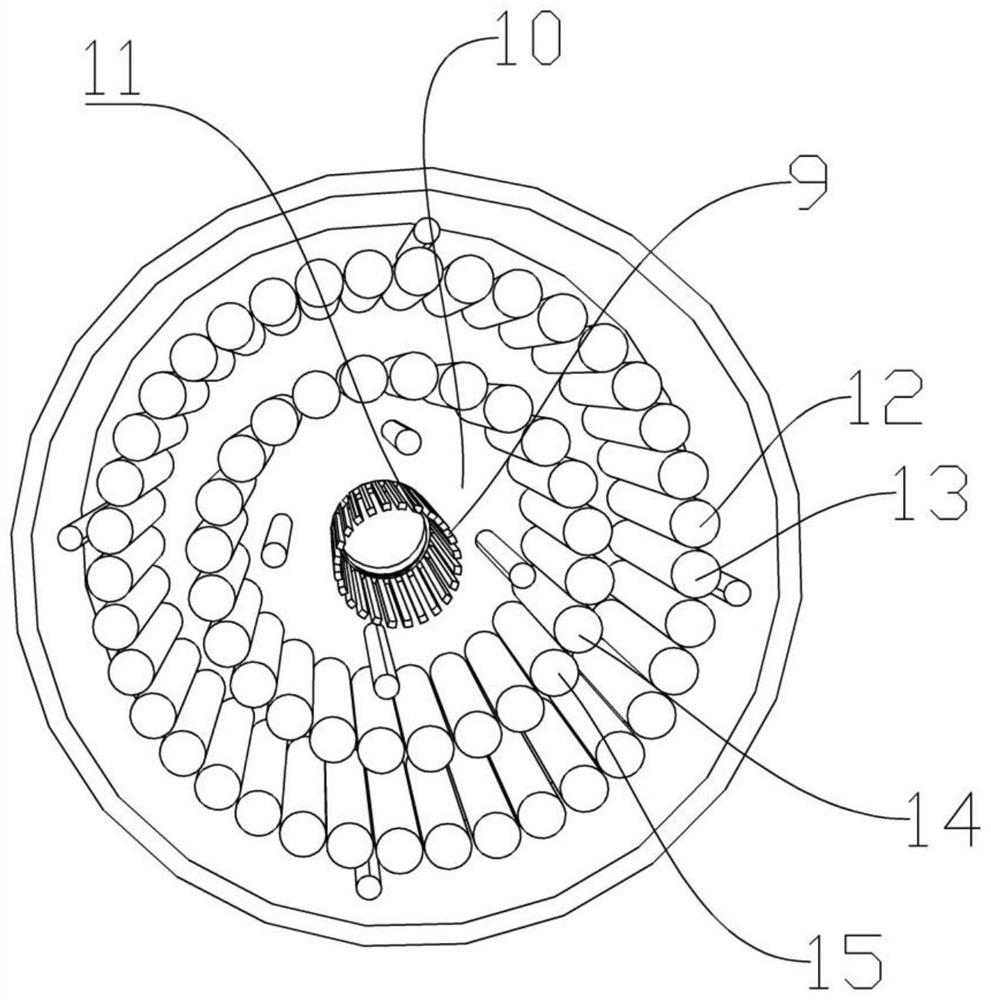

[0039] Such as Figure 1-5 As shown, a kind of rice milling machine comprises a rice milling cylinder body 2, and a first mounting plate 25 and a second mounting plate are fixed on both sides of the rice milling cylinder body 2, and the first mounting plate 25 and the second mounting plate The first rice milling assembly and the second rice milling assembly that are coaxially arranged are rotatably connected, and a plurality of rice milling rollers are all provided on the first rice milling assembly and the second rice milling assembly, and the first rice milling assembly The assembly and the second rice milling assembly are configured to be driven by the motor 4 to rotate, and the rice milling rollers are configured to rotate in opposite directions to the adjacent rice milling rollers, and the two ends of the first rice milling assembly and the second rice milling assembly are provided with The baffle plate 10, the baffle plate 10 and the rice milling roller form the first la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com