Preparation method and application of honeycomb-shaped renewable porous attapulgite adsorbent

An attapulgite and honeycomb-shaped technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of difficult recycling of powdery attapulgite and granular attapulgite Large resistance, long molding process, etc., to achieve the effect of short molding process, small mass transfer resistance, and smooth molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

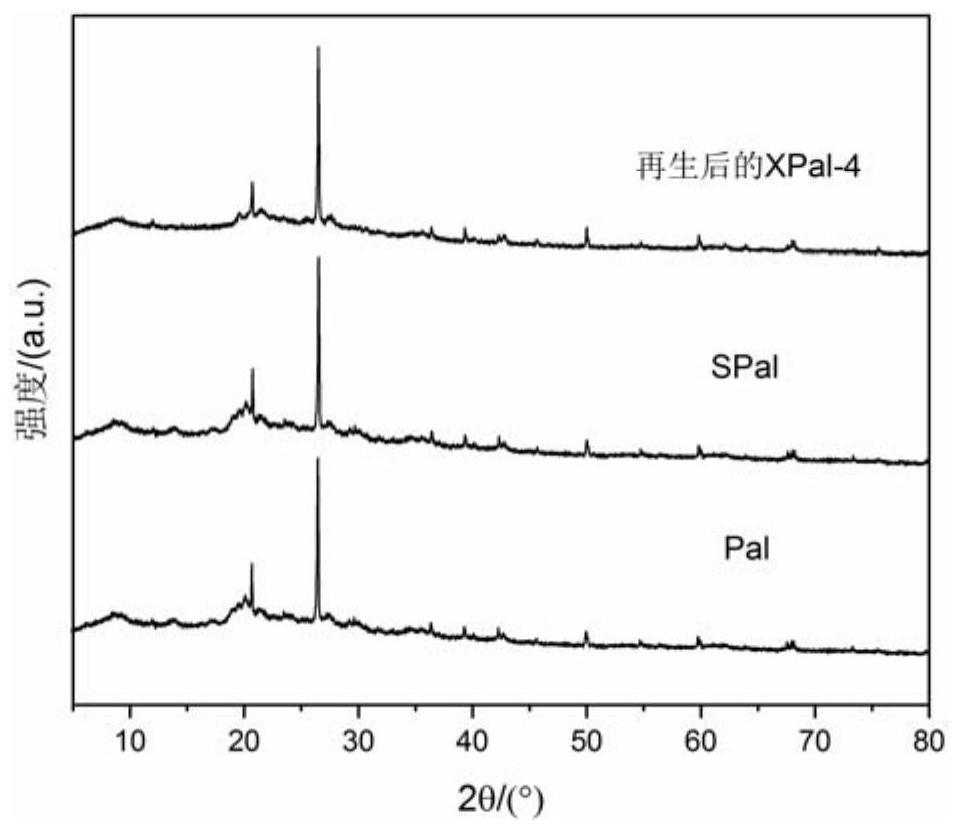

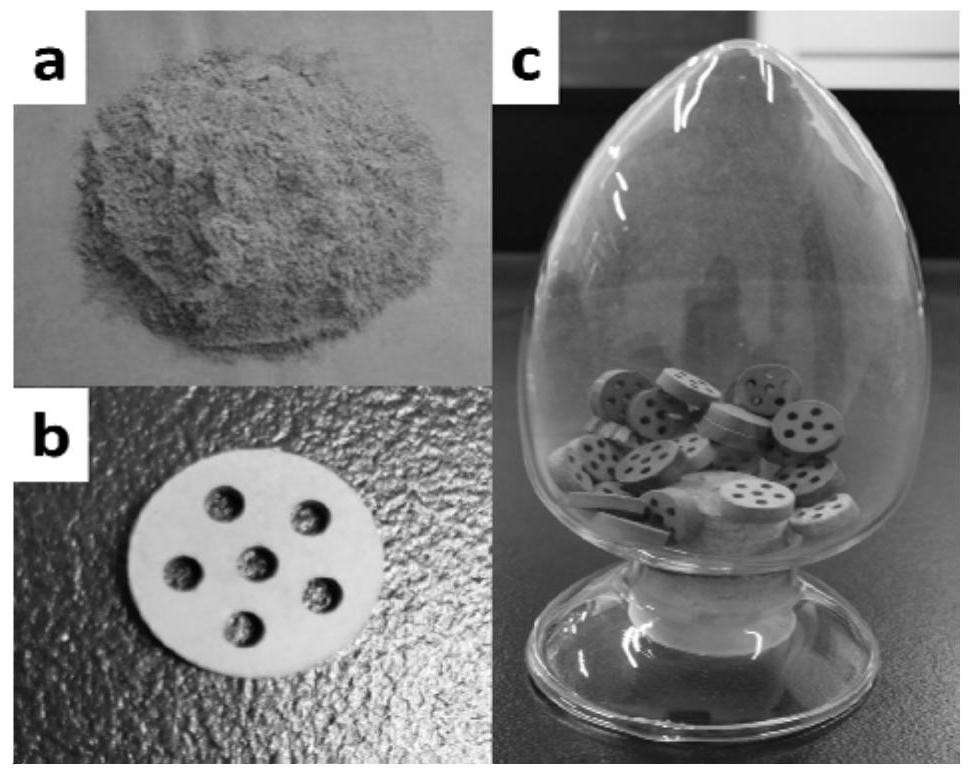

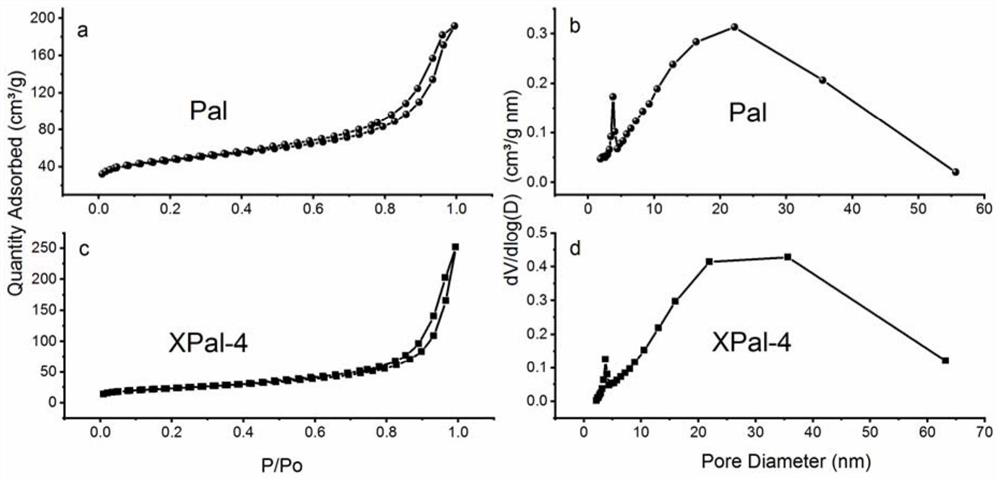

[0030] Weigh 0.45 g of natural attapulgite and 0.05 g of methyl cellulose, put them into a mortar and grind them thoroughly for 1 hour, then pour the powder into a self-designed honeycomb mold, and stand at a pressure of 7 MPa for 2 seconds to obtain a honeycomb attapulgite. The honeycomb attapulgite sheet was put into a muffle furnace and heated to 700 °C at a heating rate of 2 °C / min, calcined for 4 h, and naturally cooled to room temperature to obtain a honeycomb renewable porous attapulgite adsorbent, which was defined as XPal-1.

Embodiment 2

[0032] Weigh 0.4 g of natural attapulgite and 0.1 g of methyl cellulose, put them into a mortar and grind them thoroughly for 1 hour, then pour the powder into a self-designed honeycomb mold, and stand at a pressure of 7 MPa for 2 seconds to obtain a honeycomb attapulgite. The honeycomb attapulgite sheet was put into a muffle furnace, heated to 700°C at a heating rate of 2°C / min, calcined for 4 hours, and naturally cooled to room temperature to obtain a honeycomb-like renewable porous attapulgite adsorbent, which was defined as XPal-2.

Embodiment 3

[0034] Weigh 0.35g of natural attapulgite and 0.15g of methyl cellulose, put them into a mortar and grind them thoroughly for 1 hour, then pour the powder into a self-designed honeycomb mold, and stand at a pressure of 7Mpa for 2s to obtain a honeycomb attapulgite. The honeycomb attapulgite sheet was put into a muffle furnace, heated to 700°C at a heating rate of 2°C / min, calcined for 4 hours, and naturally cooled to room temperature to obtain a honeycomb-like renewable porous attapulgite adsorbent, which was defined as XPal-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com