Heating furnace low-NOx combustion control method based on gas fuel

A control method and gas fuel technology, which are applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of high cost of burner modification, increase energy costs, etc., to improve heat absorption efficiency, reduce NOx generation, reduce Effects of incomplete combustion losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

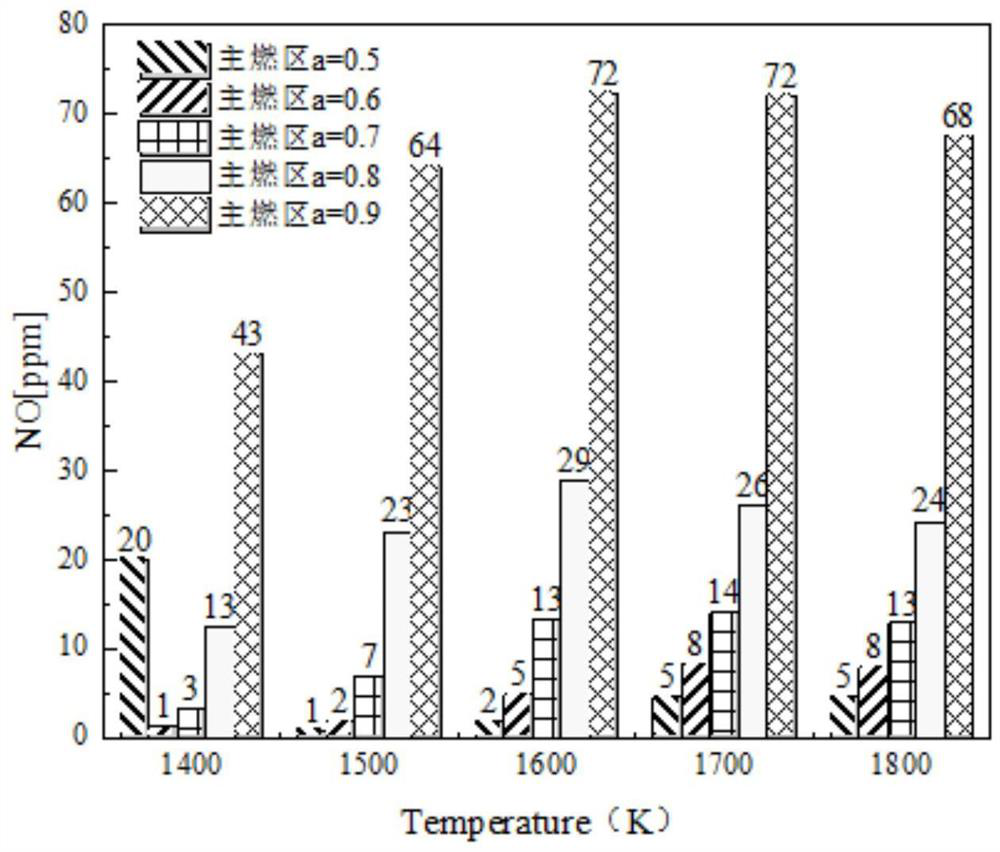

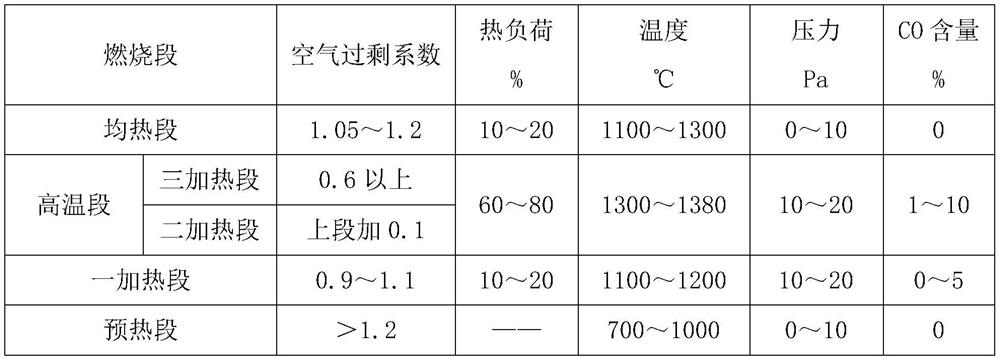

Method used

Image

Examples

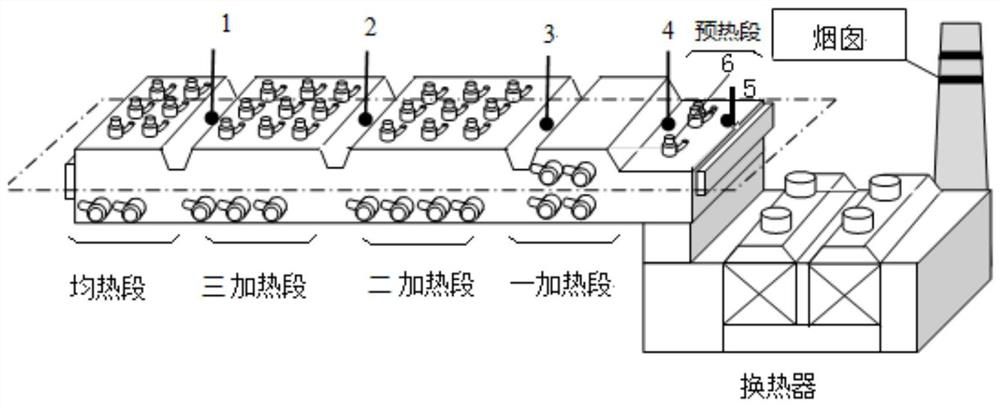

Embodiment 1

[0025] A large factory rail beam heating furnace, the design of 120T / h, the product mainly focuses on large steel, heavy rail, shaped steel, the billet is 380mm × 280mm large square billet, heating the furnace length of 35m, and the hot load is more than 70%. The heating structure is a preheating section, one heating section, two heating section, three heating section, all-heat section, due to the shortness of the heating furnace, long-term inner heat state, two heating section temperature set 1350 ° C or more, hot The temperature is set to 1300 ° C or more, and since the temperature of the heating furnace is high, the smoke NOx exceeds the standard, NOx reaches 350 mg / nm 3 Also above, the fuel consumption reaches 1.25 g of / t (hot 1200 ° C or more).

[0026] Improve the control method of the rail beam heating furnace, set a hot section gas heat load 2500 ~ 2800 nm 3 / H, air-fuel ratio 2: 1, air excess coefficient 1.05, furnace pressure 5Pa, 1 flue gas detection point detect...

Embodiment 2

[0033] A hot rolled plant slab heating furnace, the design of 250T / h, the product is mainly hot-rolled steel, silicon steel, etc., the billet is 10000 mm × 1280 mm × 230 mm large slab, the heating furnace length is 45m, and the heat is more than 30%. The heating structure is a preheating section, a heating section, two heating section, three heating sections, average heat section, due to the low heat load rate of the heating furnace, high heating temperature, hot section temperature set 1320 ° C or more, hot section The temperature is set 1280 ° C or more, due to the high temperature of the heating furnace, causing the smoke NOx to exceed the standard, reaching 320 mg / nm 3 Also above, the fuel consumption reaches 1.42 g of / t (cold).

[0034] Improved slab heating furnace control method, set a single heat section load 6000 ~ 6500nm 3 / H, air-fuel ratio 2: 1, excess coefficient 1.05, furnace pressure 7Pa, 1 flue gas detection point detection of CO.

[0035] Three heating sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com