Polyurethane shock absorber and preparation method thereof

A technology of shock absorber and polyurethane, which is applied in the field of rail transit, can solve the problems of failure to achieve the purpose of use, failure of glue opening, poor shock isolation effect, etc., and achieve the effect of not being easy to fail on the bonding surface, taking into account tight assembly, and taking into account the effect of shock absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

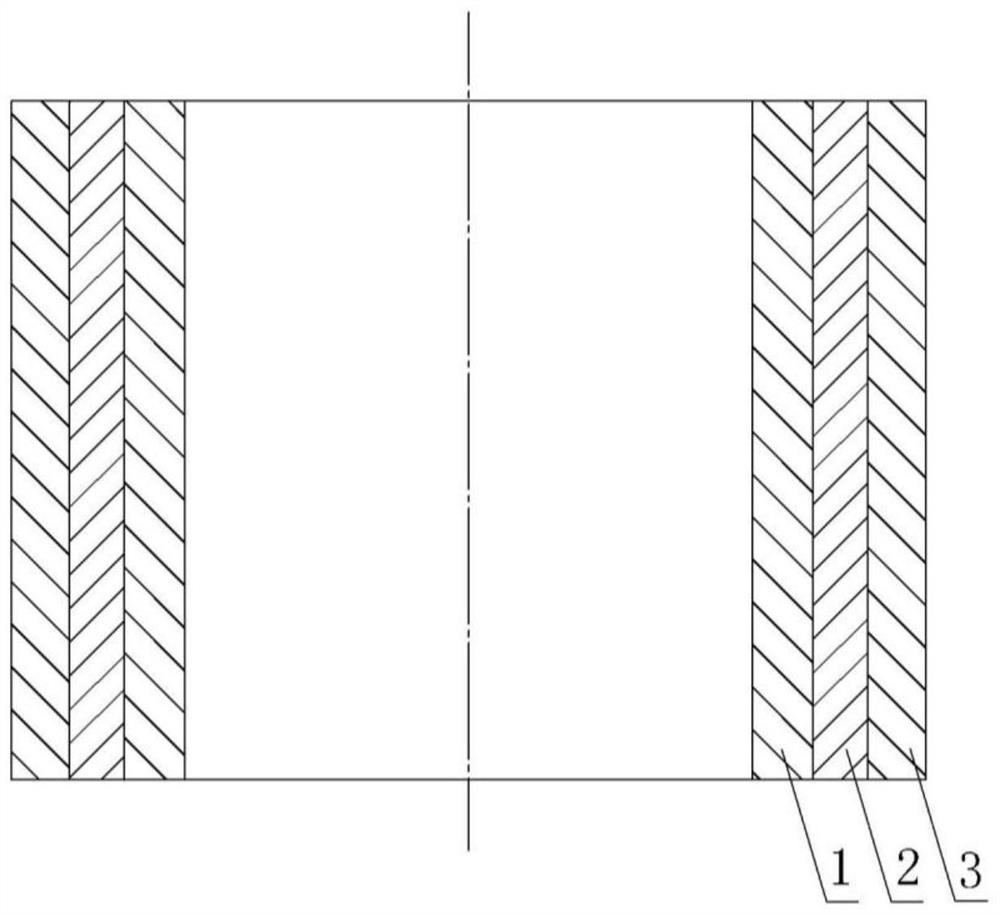

[0065] as attached figure 1 The manufacture of the multi-layer polyurethane shock absorber shown, polyurethane materials with different hardness are directly bonded by adhesive, specifically including the following steps and process conditions:

[0066] Step 1: Preparation of polyurethane prepolymer system

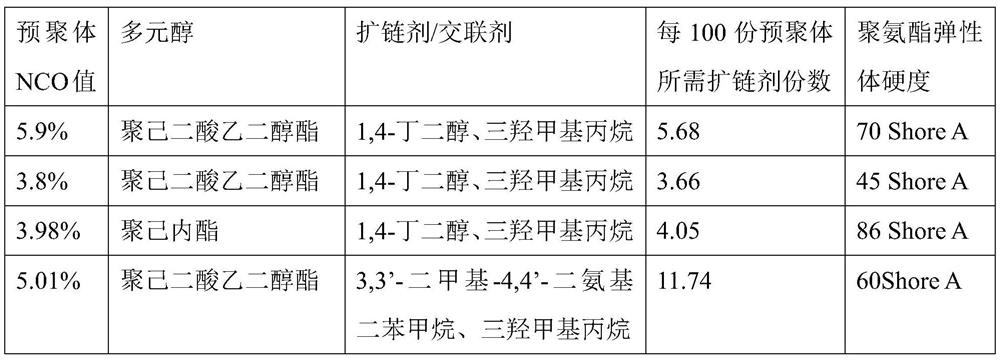

[0067] Weigh 100 parts by weight of melted polyethylene adipate with an average molecular weight of 2000, put it into a three-necked flask, heat to (110±5)°C, vacuumize to a pressure of ≤-0.08kPa, and remove moisture (1.5~ 2) h, lower the temperature to (60±5)°C, then add 37 parts of diphenylmethane diisocyanate, control the temperature at (80±2)°C, react for 2h, the measured isocyanate content is 5.9%. Debubble the polyurethane prepolymer under the condition of vacuum pressure ≤ -0.08kPa for (20±5) min to obtain polyurethane prepolymer A for inner layer polyurethane and outer layer polyurethane;

[0068] Weigh 100 parts by weight of melted polyethylene adipate with an a...

Embodiment 2

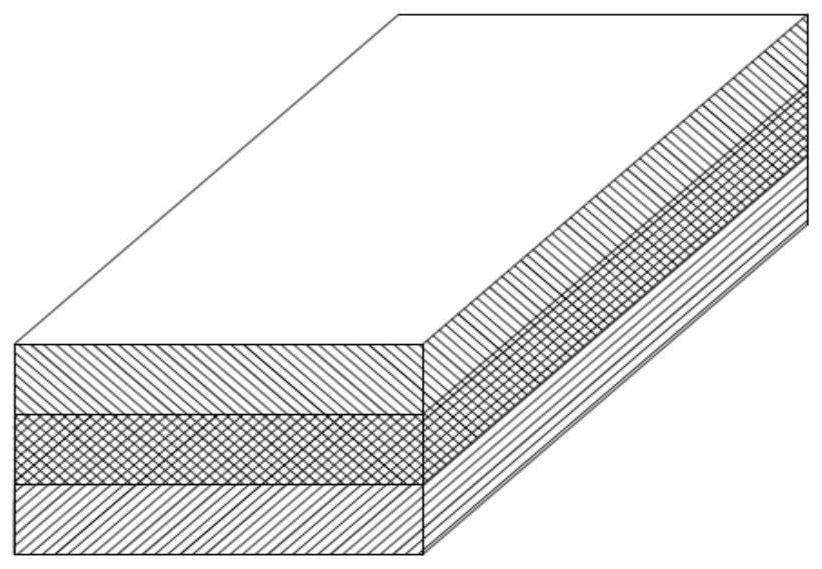

[0090] as attached figure 2 The manufacture of the multi-layer polyurethane shock absorber shown, polyurethane materials with different hardness are directly bonded by adhesive, specifically including the following steps and process conditions:

[0091] Step 1: Preparation of polyurethane prepolymer system

[0092] Weigh 100 parts by weight of melted polycaprolactone with an average molecular weight of 2000, put it into a reaction kettle, heat to (110±5)°C, evacuate to a pressure of ≤-0.08kPa, and remove moisture for (1.5~2)h, Heat to (127~135)℃, then add 23 parts of 1,5-naphthalene diisocyanate, after it melts, react at (115±5)℃ for (0.3~0.5)h, the measured isocyanate content is 3.98 %. The polyurethane prepolymer is debubbled under the condition of vacuum pressure ≤ -0.08kPa, and the polyurethane prepolymer A for the upper layer polyurethane and the lower layer polyurethane is obtained;

[0093] Weigh 100 parts by weight of melted polyethylene adipate with an average mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com