SO2 depolarization electrolytic tank and operation method thereof

An operation method and electrolytic cell technology, applied in electrolytic processes, electrolytic components, cells, etc., can solve problems such as membrane electrode assembly SDE electrolytic cell failure, proton passing capacity decline, resistance increase, etc., to achieve fine particles, strong maintainability Sexuality and the effect of preventing performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

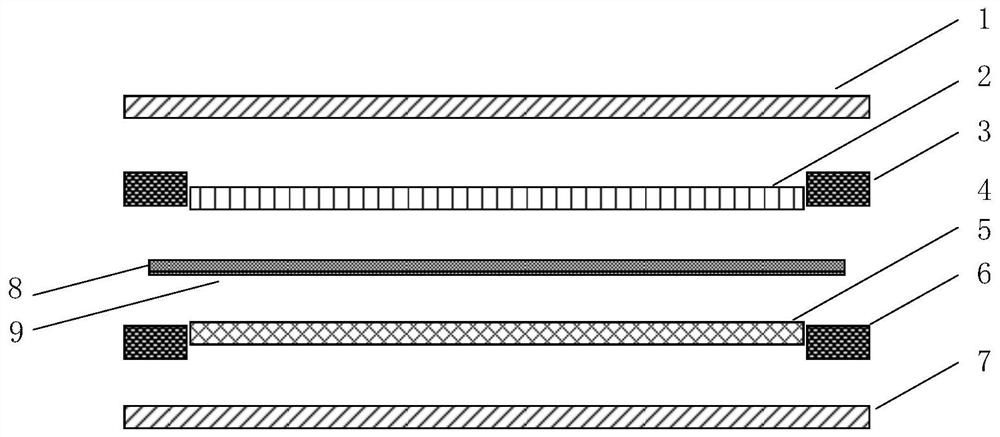

[0042] Using the scheme of the present invention, the SO 2 Depolarize the electrolytic cell. The membrane electrode assembly of the electrolytic cell is composed of an anode catalyst layer and a proton selective permeable membrane. A cathode sealing ring is wrapped around the supporting body on the cathode side, and an anode sealing ring is wrapped around the supporting body on the anode side. The anode side of the electrolytic cell has an anode material inlet and an anode material outlet; the cathode side has a product hydrogen discharge port. The membrane electrode assembly is composed of an anode catalyst layer, a proton selective permeable membrane, and a cathode side support is loaded with a catalyst.

[0043] The effective membrane area of each cell is 50cm 2 , where the proton selective permeation membrane is selected from DuPont's Nafion117 proton exchange membrane, and the anode side is sprayed with a Pt / C catalyst layer, and the amount of Pt used is 0.4mg / cm 2 ...

Embodiment 2

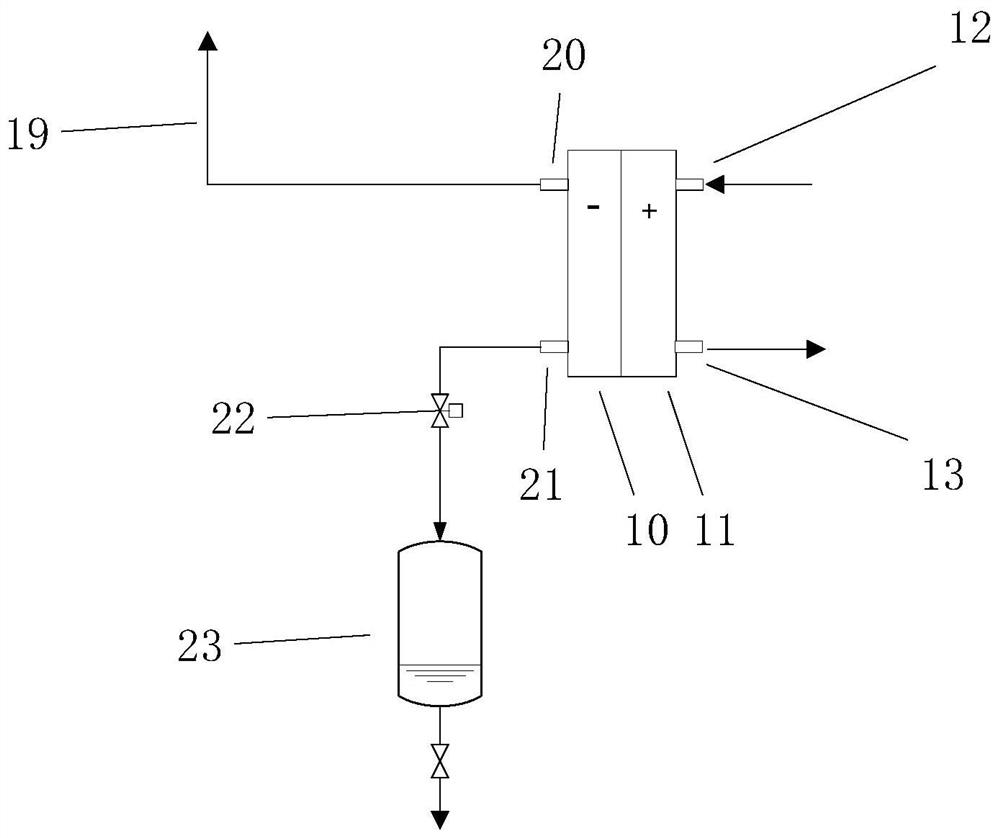

[0050] SO in Example 1 2 Depolarize the electrolytic cell, remove the cathodic washing liquid storage tank, cathode washing pump, cathodic washing liquid recovery storage tank, and auxiliary pipelines and valves equipped on the cathode side. image 3 As shown in the configuration, the cathode side is equipped with a pressure relief port 21, a pressure relief valve 22, a pressure relief drainage recovery tank 23 and ancillary pipelines.

[0051] At 60°C, with the above SO 2 The depolarized electrolytic cell performs electrolysis operation, and the anode material is saturated SO 230wt.% sulfuric acid, the external direct current keeps the current constant at 25A, the total cell voltage is 5.6V, and the hydrogen production rate in the cathode area is measured to be ~60L / h.

[0052] The cathode side of the electrolytic cell operates under the condition of 1.5 atmospheric pressure, and the initial setting pressure of the pressure relief drainage recovery tank is 1 atmospheric pre...

Embodiment 3

[0054] Using the solution of the present invention, the SO 2 Depolarize the electrolytic cell. The membrane electrode assembly of the electrolytic cell is composed of an anode catalyst layer and a proton selective permeable membrane. The anode side of the electrolytic cell has an anode material inlet and outlet; the cathode side has two product hydrogen discharge ports. The membrane electrode assembly is composed of an anode catalyst layer, a proton selective permeable membrane, and a cathode side support is loaded with a catalyst.

[0055] The effective membrane area of each cell is 100cm 2 , where the proton selective permeable membrane is selected from DuPont's Nafion115 proton exchange membrane, and its anode side has a Pt / C catalyst layer, and the amount of Pt used is 0.3mg / cm 2 , the cathode side of the proton-selective permeable membrane has no catalyst layer. The cathode side support body is 2.5mm thick graphite felt (porosity 92%, carbon content 99.9%), is loade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com