Construction method of pre-embedded cable pipes for fan foundation in mountainous wind power projects

A wind turbine foundation and wind power engineering technology, which is applied in the direction of cable installation in underground pipelines, cable installation, installation/supporting wind turbine configuration, etc., to achieve the effects of stable passage, convenient transportation, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

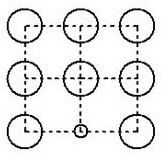

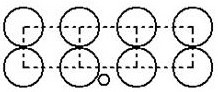

[0039] Below in conjunction with accompanying drawing, the present invention is further explained and illustrated:

[0040] see Figure 1 ~ Figure 4 , a construction method for pre-embedded cable pipes for fan foundations in mountainous wind power projects. Eight CPVCs with a diameter of 125 mm and one CPVC cable pre-embedded pipes with a diameter of 50 mm are reserved in the fan foundation, and they are wrapped by concrete pouring. After the fan is hoisted in place, use cables to pass through the cable fiber from the side of the fan along the cable pre-buried pipe to the box-type transformer, so as to transmit the electric energy generated by the fan rotation to the box-type transformer, including the following specific steps:

[0041] A. Fan foundation excavation:

[0042] Before the excavation of the fan foundation, find the coordinates and elevation of the center point of the fan, use GPS to measure the center position of the fan foundation, and release the outer edge lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com