A kind of lithium battery separator based on biomass furan-based polymer and preparation method thereof

A lithium battery diaphragm and polymer technology, applied in the direction of lithium batteries, non-aqueous electrolyte batteries, battery components, etc., can solve the problems of demanding molecular weight of aramid fiber, poor electrolyte wettability, high cost of coating process, etc., to achieve Good thermal stability and electrolyte wettability, improved rate performance and cycle stability, improved convenience and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

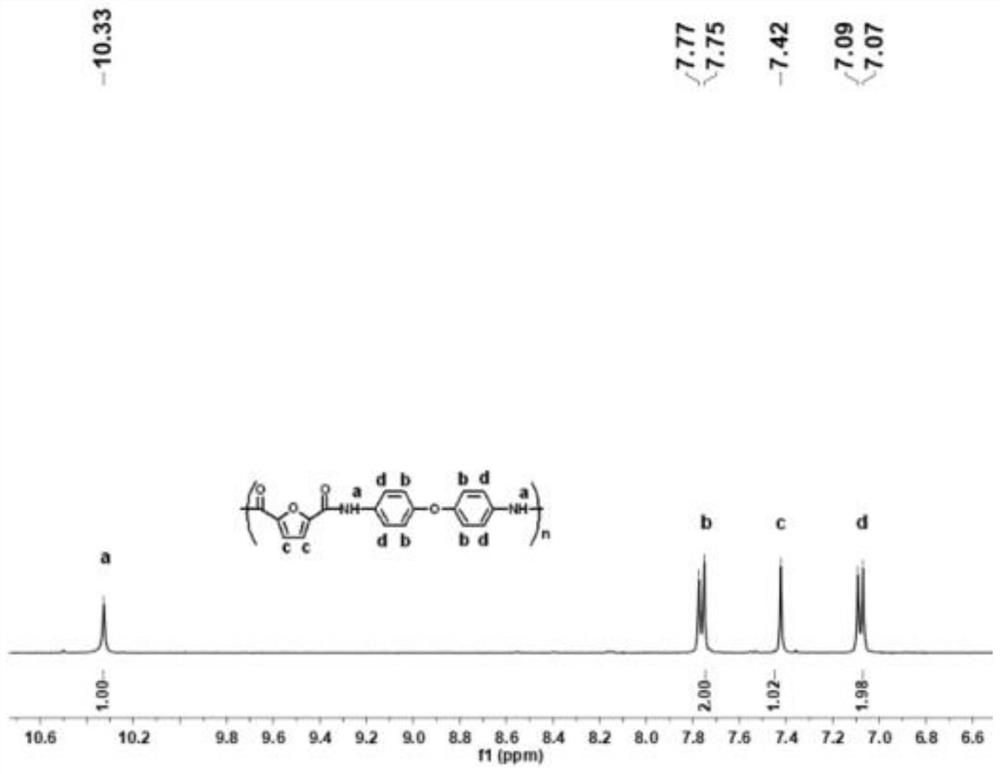

[0042] Preparation of polymer A: add solvent N,N-dimethylacetamide 10L, 2,5 furandiformyl chloride 192g, 4,4'-diaminodiphenyl ether 200g sequentially at 25°C, and react for 5h , the solvent was evaporated to dryness under reduced pressure to obtain polymer A.

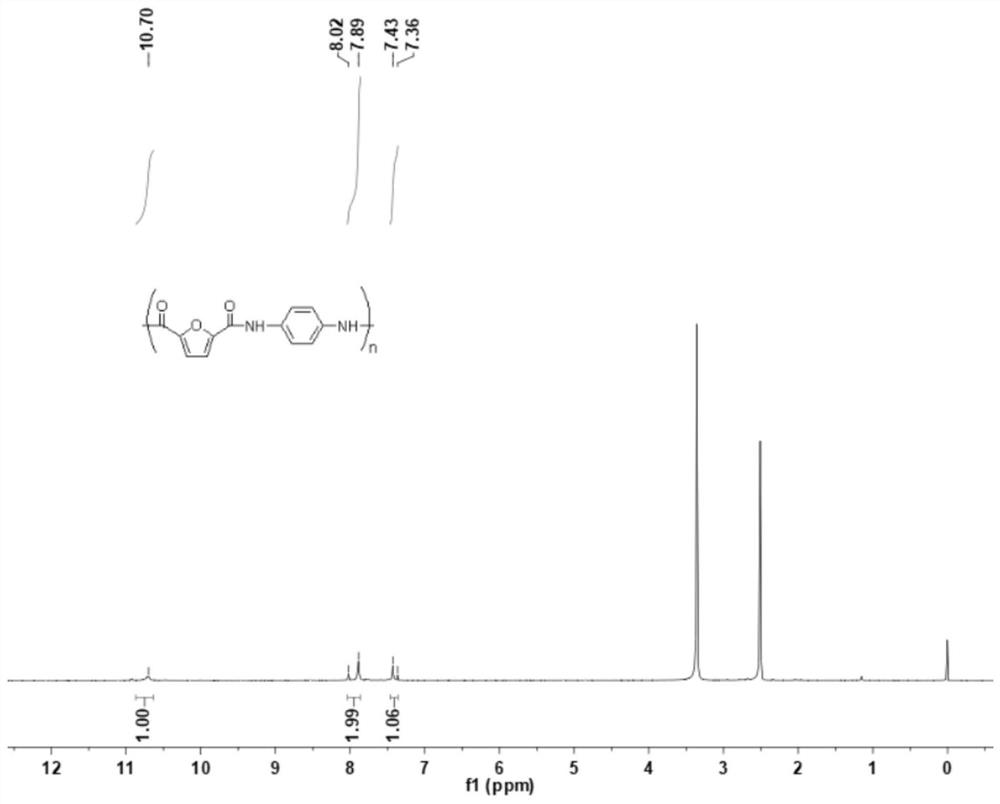

[0043] Preparation of polymer B: Add solvent N,N-dimethylacetamide 10L, 2,5-furandiformyl chloride 192g, p-phenylenediamine 108g in sequence to the polymerization reaction kettle at 25°C, react for 5h, evaporate to dryness under reduced pressure solvent to obtain polymer B.

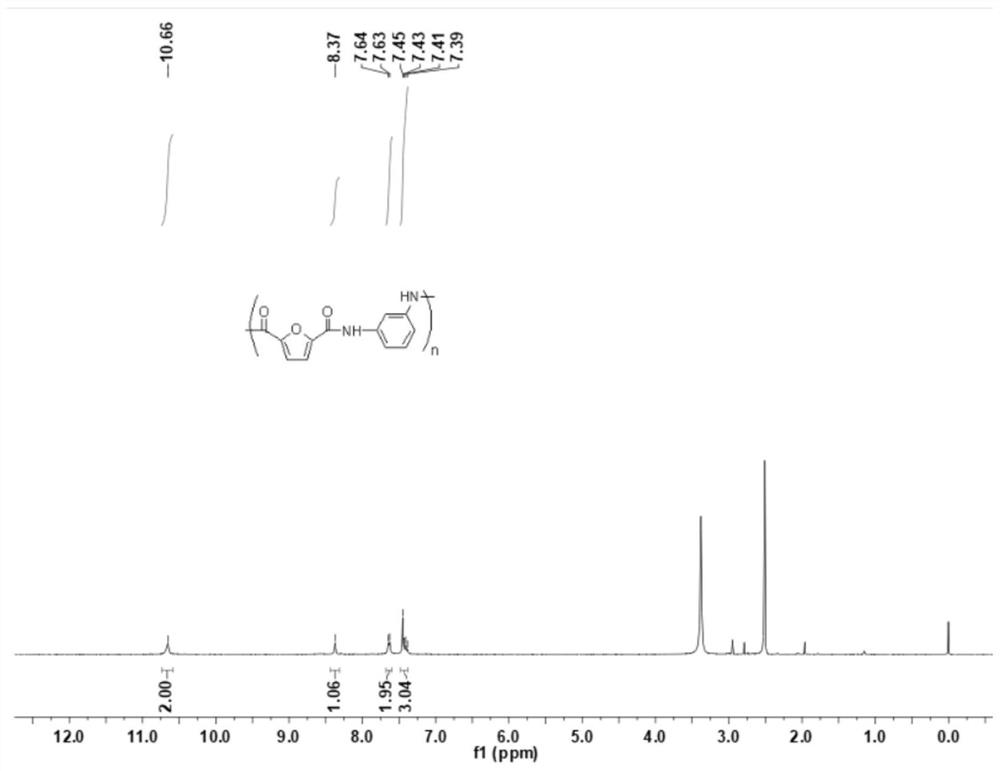

[0044] Preparation of polymer C: 10L of solvent N,N-dimethylacetamide, 192g of 2,5-furandiformyl chloride, 108g of m-phenylenediamine were added to the polymerization reaction kettle in turn at 25°C, reacted for 5h, and evaporated to dryness under reduced pressure solvent to give polymer C.

Embodiment 1

[0046] Add 3kg of biomass furan-based polymer A powder to 100kg of N,N-dimethylacetamide with a purity greater than 99%, stir for 30min to completely dissolve, and then add 90g of polyethylene oxide with an average molecular weight of 500,000, 3kg of silicon oxide and 3kg of n-octane were used to prepare biomass furan-based polymer A coating slurry, and the reaction was carried out under the protection of nitrogen. The coating slurry was coated with 0.1% SiO 2 On the PP blend film, immersed in water for 60 min, and dried at 80 °C to form a film.

Embodiment 2

[0048]Add 3kg of biomass furan-based polymer B powder to 100kg of N-methyl-2-pyrrolidone with a purity greater than 99%, stir for 30min to completely dissolve, then add 60g of polyvinyl alcohol with an average molecular weight of 2000, 1kg of oxidized Titanium, 3kg isopropanol, to prepare biomass furan-based polymer B coating slurry, the reaction is carried out under the protection of nitrogen. The coating slurry was coated with 0.1% SiO 2 On the PP blend film, immersed in water for 30 min, and dried at 100 °C to form a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com