Assembly type wall surface system and mounting method thereof

A prefabricated, wall panel technology, applied in building components, thermal insulation, sound insulation, etc., can solve the problems of low construction efficiency, high technical requirements for installation workers, and large environmental pollution, and achieves an increase in the moment of inertia of the section, fast and effective leveling , the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

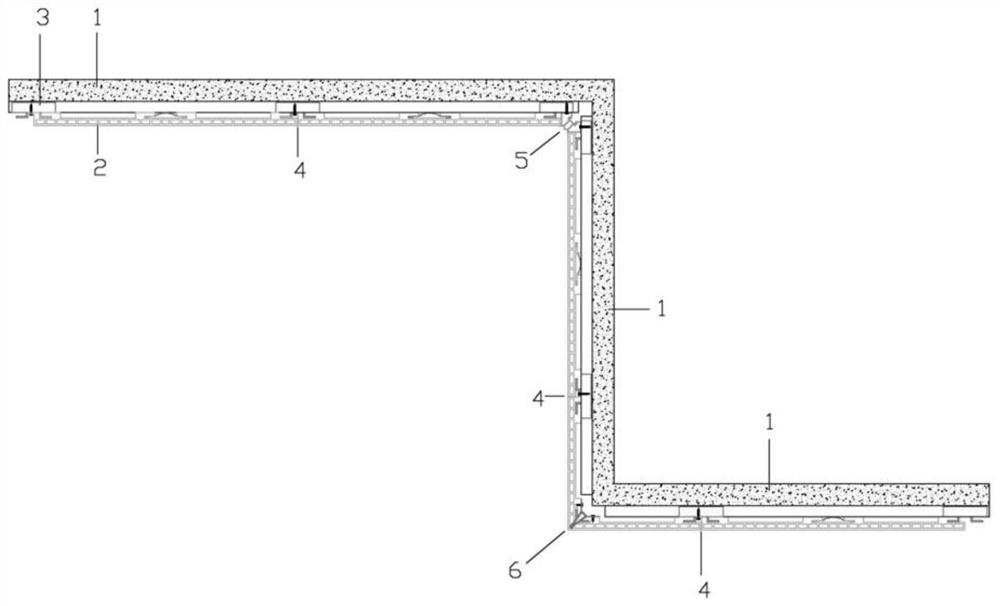

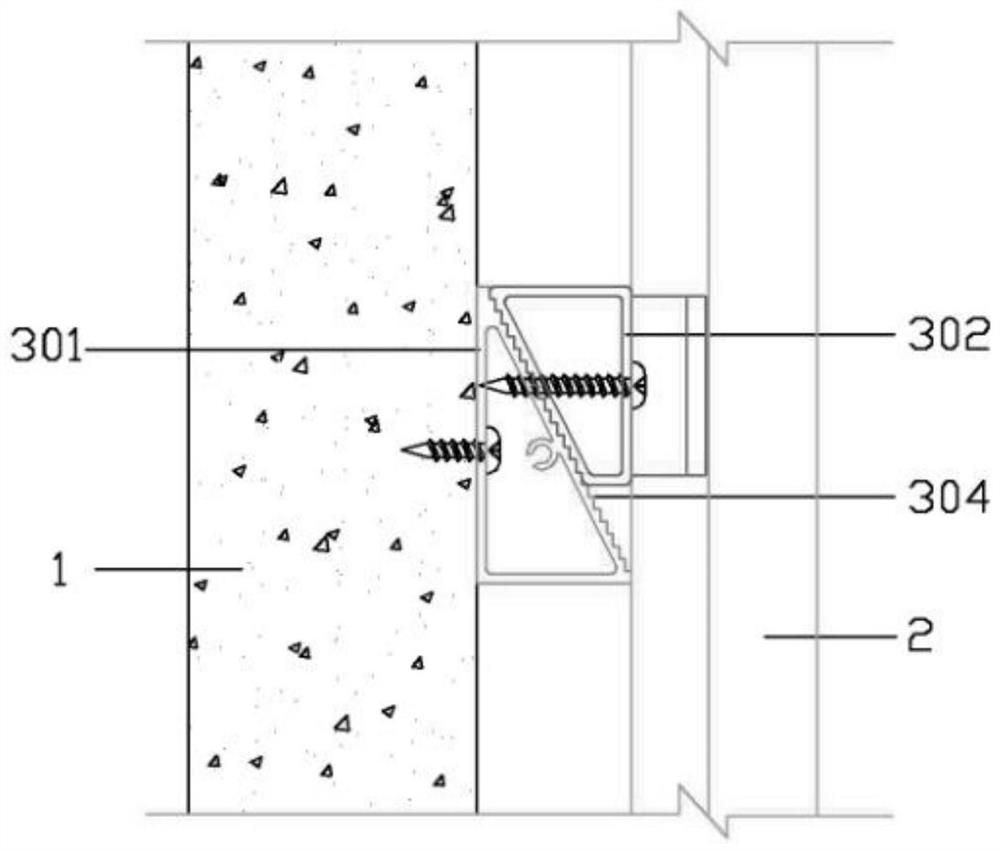

[0066] The modular wall panel 2 is set on the original wall surface 1 through the triangular keel leveling system 3, and the modular wall panels 2 are connected through the wall panel joint system 4. The bottom of the original wall surface 1 is equipped with a magnetic skirting system 7. The top of the original wall 1 is provided with a top trimming system 9, the original wall 1 is provided with a detachable inner corner system 5 at the inner corner, and the original wall 1 is provided with an integral outer corner at the outer corner System 6, the original wall surface 1 is provided with a door side panel system 8 at the position of the door.

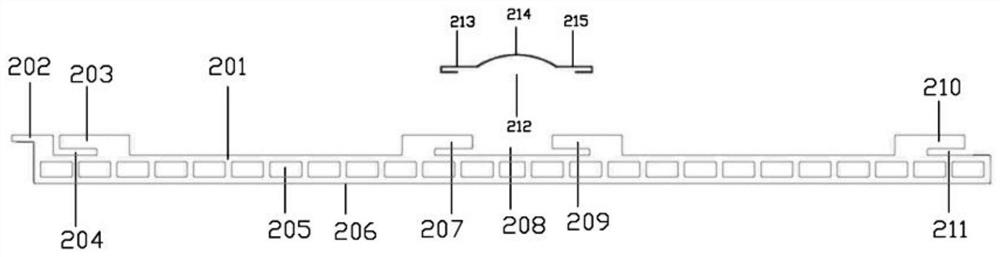

[0067] The modular wall panel 2 includes an extruded plastic wall panel 201, the back of one end of the extruded plastic wall panel 201 is provided with a chute structure 204, the back of the other end of the extruded plastic wall panel 201 is provided with a slot structure 211, and the back of the extruded plastic wall panel 201 There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com