Biosynthetic drilling fluid and preparation method thereof

A biosynthesis and drilling fluid technology, applied in the field of oil and gas exploration and development, can solve the problems of the environment containing aromatic hydrocarbons, strong biological toxicity, and low environmental pollution, and achieve the effects of small environmental hazards, good rheological properties, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a density 1.60g / cm 3 , The oil water ratio is 80:20 biosynthetic base drilling fluid, which is prepared from the following weight percentage of raw materials: biodiesel 320ml, 6.0g of the organic soil, 14.0g of the main emulsifier, 8.0g, lime 10.0g, quality concentration For 26% of the calcium chloride solution 80ml, the filter dosage is 16.0g, a wetting agent 2.0g, a stream modulator 3.2 g, and a crystalline stone powder 400g.

[0037] The preparation method is as follows:

[0038] (1) Add biodiesel to the high mixture, add organic soil to stir at 11000 r / min at high speed;

[0039] (2) While stirring at high speed, the primary emulsifier continues to be added to stir at 11000 r / min at high speed;

[0040] (3) While stirring at high speed, the carbonate is continued to be added to 11000 r / min at a high speed of 20 min;

[0041](4) While stirring at high speed, the alkalin regulatagent lime is continued to stir at 11000 r / min at high speed...

Embodiment 2

[0048] This embodiment provides a density 2.30g / cm 3 , Oil-water ratio of biosynthesis liquid ratio of 90:10: it is prepared from the following weight of raw materials: biodiesel 360mL, 6.0g, main emulsifier 16.0g, carimetifier 8.0g, quality The concentration of 26% aqueous solution of calcium chloride is 40 ml, a lifting filter dosage 16.0g, a wetting agent 2.0g, a stream modulator 2.0 g, and a crystalline stone powder 1000g.

[0049] Its preparation method is the preparation method described in Example 1.

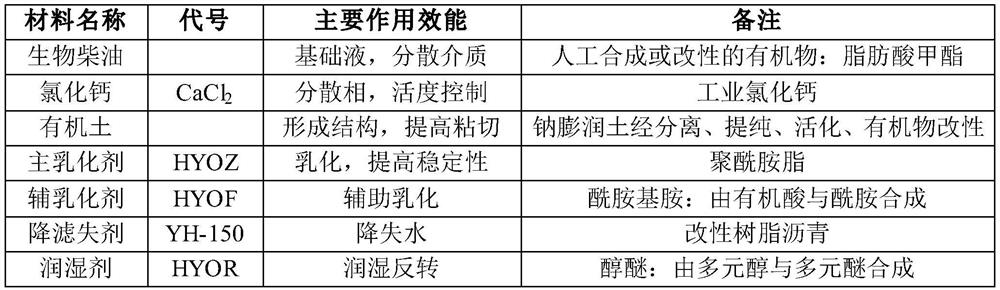

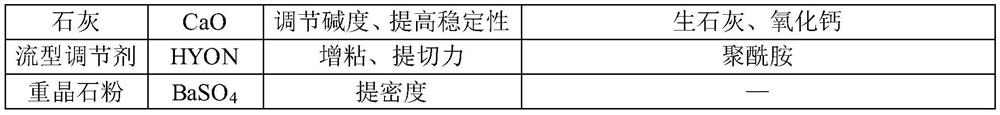

[0050] Example 1, the raw materials of Example 2 were sold in the market. They were strictly used in accordance with industry standards or enterprises in the purchase. Specifically, see Table 1

[0051] Table 1 Biosynthetic drilling fluid raw material bright table

[0052]

[0053]

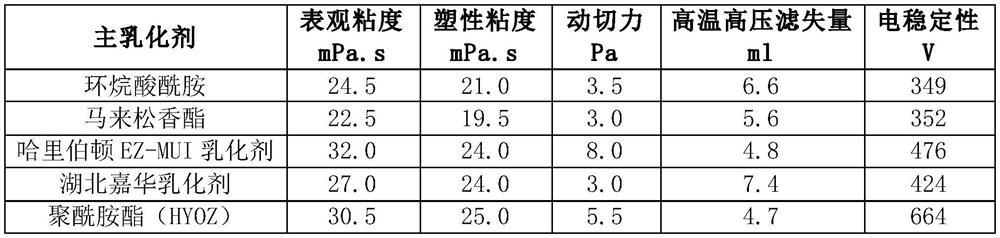

[0054] 1. Comparative evaluation of the emulsifier emulsification effect

[0055] 2% main emulsifier was added to 240 ml of synthetic drilling fluid (biodiesel), stirred at a high speed for...

Embodiment 3

[0070] In this embodiment, the chemical properties of one biosynthetic drilled well prepared in Examples 1 and Example 2 were examined in this example:

[0071] 1. Evaluation of anti-high temperature effects

[0072] The formulated biosynthetic drilling fluid is rolled at different temperatures, and the constant temperature aging is 16h, cooling to 50 ° C to measure its rheology and electrical stability, and evaluate the temperature effect of biosynthetic drilled well fluid, and the measurement results are shown in Table 5.

[0073] Table 5 Rheological parameters under normal temperature of biosynthetic drilling fluid

[0074]

[0075]

[0076] It can be seen from Table 5 above: 2.30g / cm of density 3 And 1.60g / cm 3 The biosynthetic drilling fluid has a good resistance effect. When the temperature is less than 160 ° C, the high temperature high-pressure filter loss of the biosynthetic drilled well is controlled within 3.0 ml, and the drilling liquid filtration can be effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com