Zinc oxide microsphere, electrode and preparation method thereof

A zinc oxide micron, zinc oxide technology, applied in the field of lithium-ion batteries, can solve the problem of low capacity growth, and achieve the effect of improving cycle life, increasing contact area, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

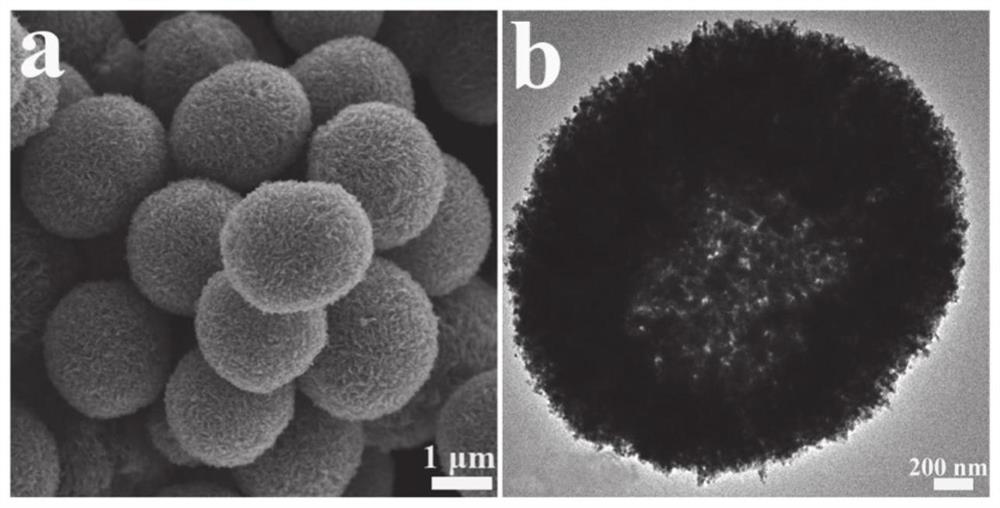

[0026] Embodiment 1: the preparation method of zinc oxide hollow microspheres comprises the steps:

[0027] 1) Preparation of mixed solution: ultrasonically mix 0.20 mmol of zinc acetate dihydrate and 21 mL of isopropanol, then add 3 mL of glycerol, and mix uniformly by magnetic stirring to obtain a mixed solution; zinc acetate dihydrate is uniformly dispersed in the mixed solution ;

[0028] 2) Preparation of zinc-glycerate by mixed liquid reaction: Pour the mixed liquid into a reaction kettle, place it in an oven at 180°C for 2 hours, then cool the reaction kettle to room temperature, obtain a precipitate by centrifugation, and wash with absolute ethanol for 5 Remove the unreacted alcohols for the first time, and then put it into a 70°C oven to dry to obtain zinc glycerate;

[0029] 3) Zinc glycerate is calcined to prepare zinc oxide microspheres: Zinc glycerate is used as a precursor, put in a porcelain boat and placed in a tube furnace, and the temperature is raised at a ...

Embodiment 2

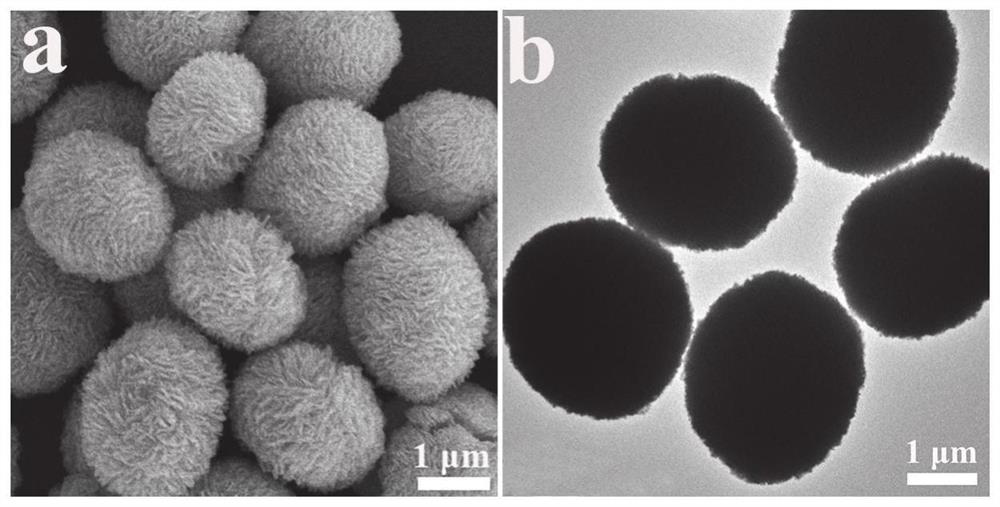

[0038] Embodiment 2: the preparation method of zinc oxide solid microsphere, comprises the steps:

[0039] 1) Preparation of mixed solution: ultrasonically mix 0.25 mmol of zinc acetate dihydrate and 20 mL of isopropanol, then add 4 mL of glycerol, and mix uniformly by magnetic stirring to obtain a mixed solution; zinc acetate dihydrate is uniformly dispersed in the mixed solution ;

[0040] 2) Preparation of zinc-glycerate by mixed liquid reaction: Pour the mixed liquid into a reaction kettle, place it in an oven at 180°C for 6 hours, then cool the reaction kettle to room temperature, obtain a precipitate by centrifugation, and wash 5 times with absolute ethanol The unreacted alcohols were removed, and then put into an oven at 70° C. to dry to obtain zinc glyceric acid salt.

[0041] 3) Zinc glycerate was calcined to prepare zinc oxide microspheres: take the prepared zinc glycerate as a precursor, put it into a porcelain boat and place it in a tube furnace, and heat it at 2°...

Embodiment 3

[0050] Embodiment 3: the preparation method of zinc oxide solid microspheres, it comprises the steps:

[0051] 1) Preparation of mixed solution: ultrasonically mix 0.15 mmol of zinc acetate dihydrate and 20 mL of isopropanol, then add 4 mL of glycerol, and mix uniformly by magnetic stirring to obtain a mixed solution; zinc acetate dihydrate is uniformly dispersed in the mixed solution ;

[0052] 2) Preparation of zinc-glycerate by mixed liquid reaction: Pour the mixed liquid into a reaction kettle, place it in an oven at 180°C for 6 hours, then cool the reaction kettle to room temperature, obtain a precipitate by centrifugation, and wash with absolute ethanol for 5 Remove unreacted alcohols for the first time, and then put it into a 70°C oven to dry to obtain zinc glycerate;

[0053] 3) Zinc glycerate was calcined to prepare zinc oxide microspheres: Zinc glycerate was put into a porcelain boat as a precursor and placed in a tube furnace, and heated at a rate of 2°C / min to 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com