A method for starting or anti-stalling of a DC brushed motor

A DC brushed motor and motor rotor technology, which is applied to the starter of a single DC motor, the deceleration device of an AC motor, the motor generator/starter, etc., can solve the problem that the brushed DC motor cannot be started by itself and is not easy to start And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below with reference to the accompanying drawings and specific embodiments.

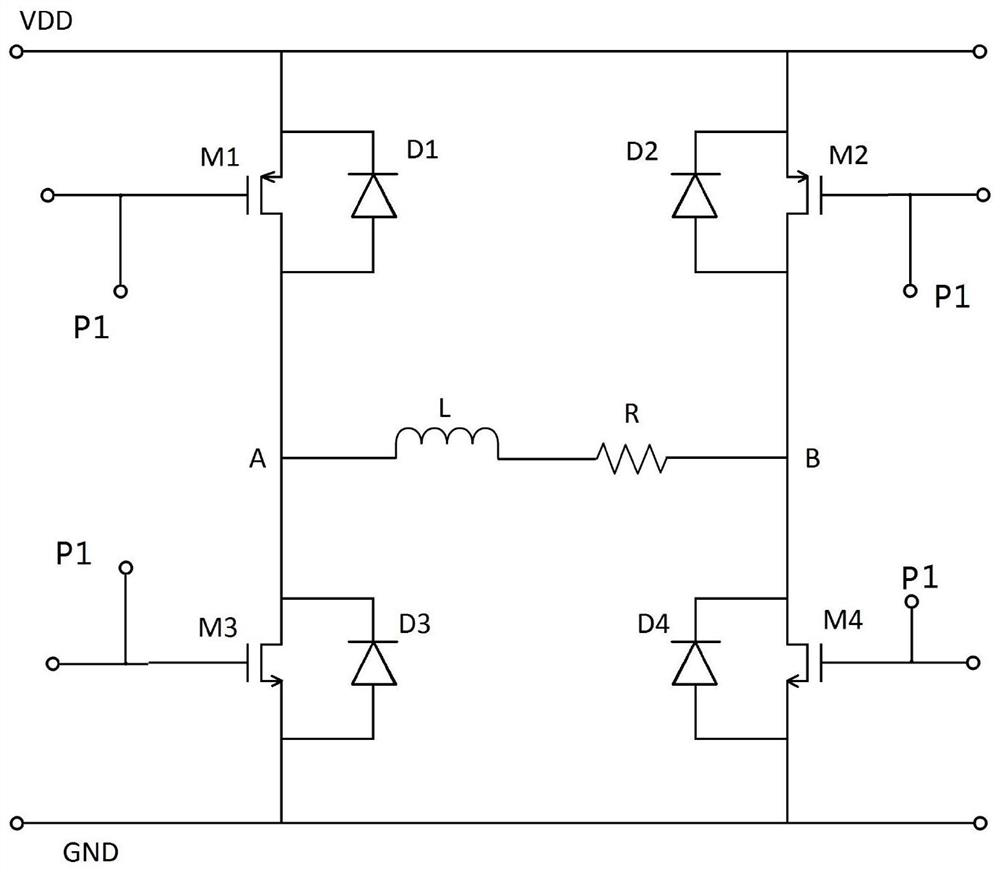

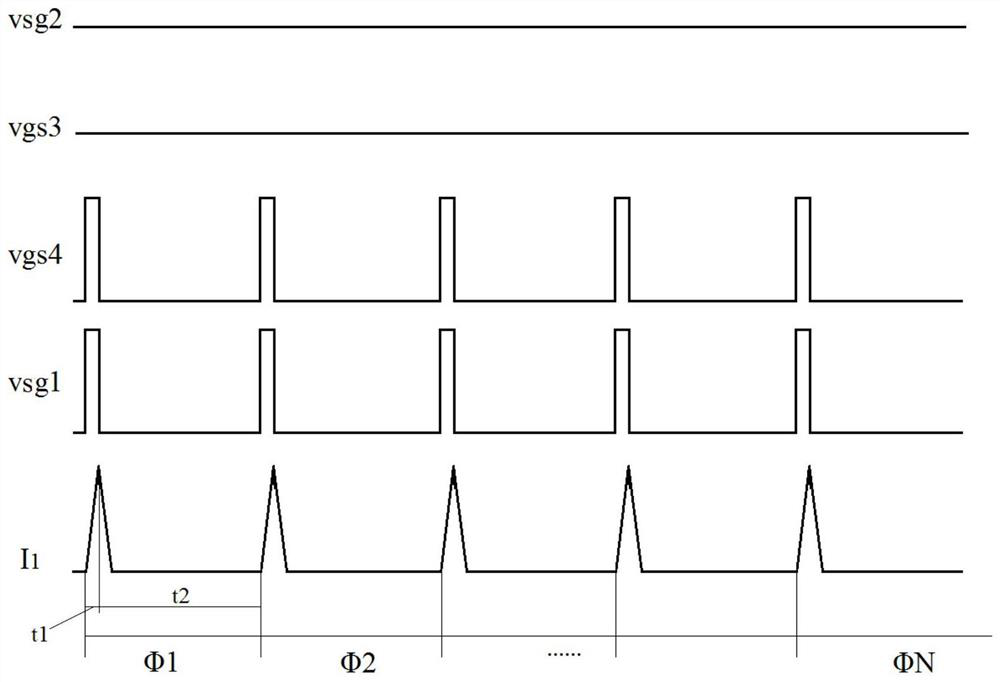

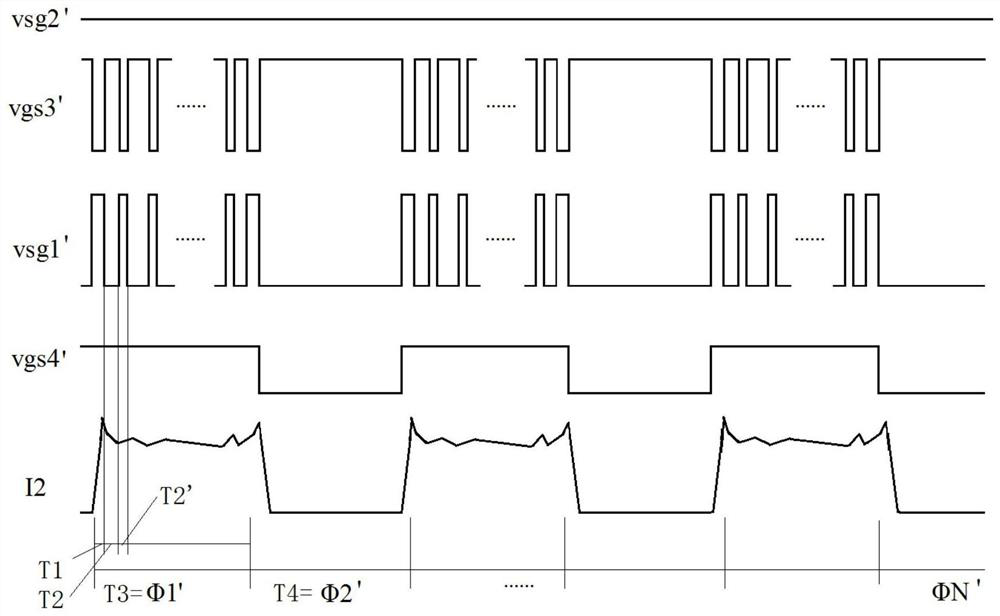

[0030] A method for starting or anti-stalling of a DC brush motor is different from the prior art in that, in addition to including a traditional overcurrent protection circuit, an overtemperature protection circuit and figure 1 The shown H-bridge drive circuit also includes a PWM control module, and the PWM control module P1 controls the first high-side PMOS switch M1, the second high-side PMOS switch M2, the third high-side PMOS switch M2, and the third respectively according to the modulation time and the modulation current threshold Ipwm. The low-side NMOS switch M3 and the fourth low-side NMOS switch M4 are turned on and off. The PWM control module P1 is preset with a modulation current threshold Ipwm and a modulation current start time tp, the modulation current thres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com