Equipment and method for detecting size of circular tube by using X-ray imaging technology

A technical detection and X-ray technology, which is applied in the field of equipment that uses X-ray imaging technology to detect the size of round tubes, can solve the problems of low measurement efficiency, small sampling data ratio, and low accuracy, so as to reduce the loss of adjustment materials and improve Detecting the sampling ratio and improving the effect of wall thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

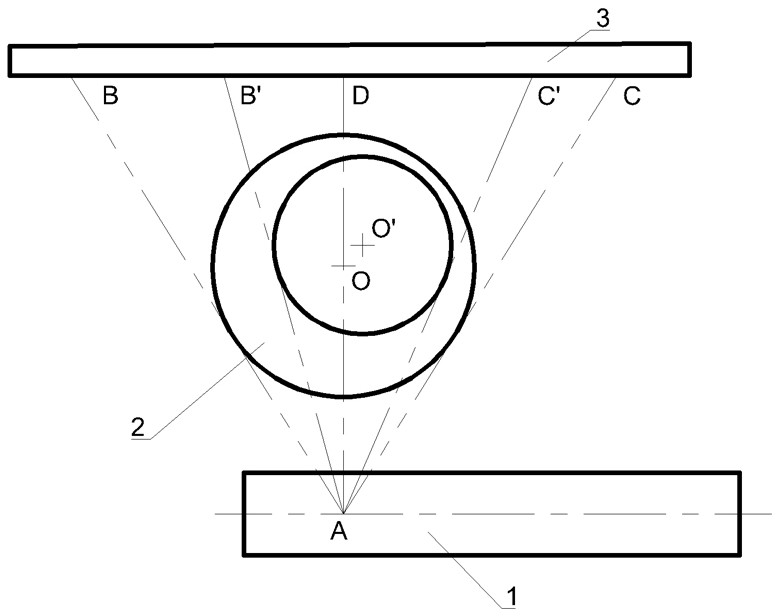

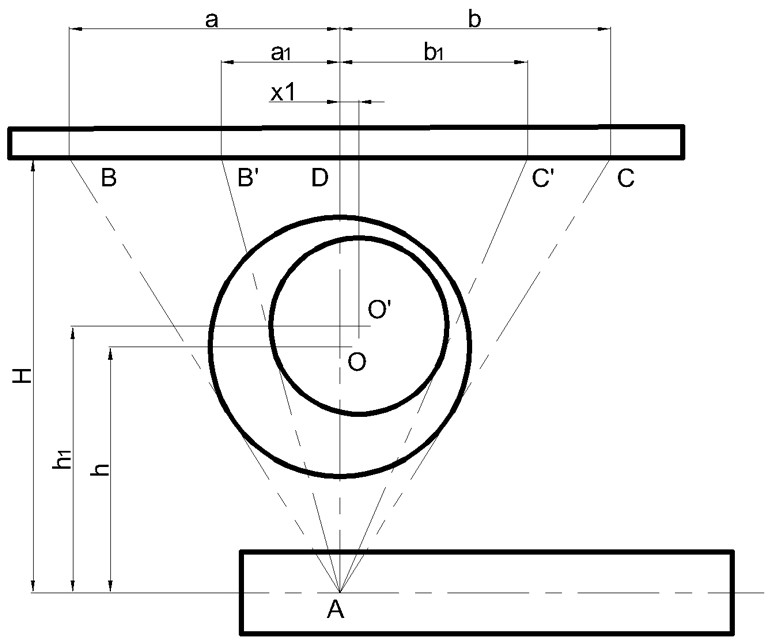

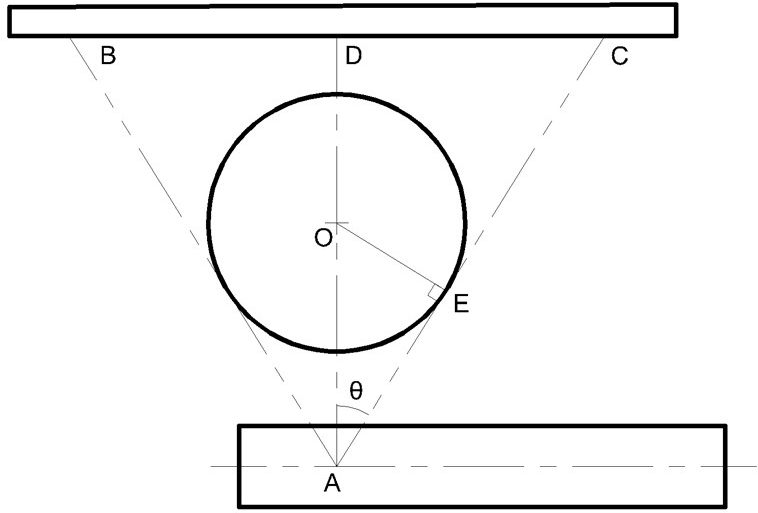

[0052] With reference to accompanying drawing, the equipment that uses X-ray imaging technology to detect the size of round tubes includes a machine base and a casing 7. Two groups of rollers 12-13 arranged up and down are installed on the supports on both sides of the machine base. The opening 4 where the tube enters and exits, the X-ray emitter 9 is installed on the support and in the middle of the brackets on both sides, and the imaging plate 15 corresponding to the X-ray emitter is installed on the opposite side above the emitter through a movable bracket; The opening where the round tube enters is fixed with a radiation-proof curtain; the imaging plate is connected to the movable support through a worm gear 11 with a self-locking structure, and the worm is movably connected to the machine base through a bearing, and a handle 8 is fixed above the worm, and the handle wears Above the casing, a worm gear that matches the worm is provided on the movable support, and at the sam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap