Oil and gas pipeline plugging method

A technology for oil and gas pipelines and oil walls, applied in pipeline protection, pipeline heating/cooling, and pipeline protection through heat insulation, etc., can solve the problems of pipeline coldness and brittleness, lower the freezing point, and increase the energy consumption of freezing, so as to improve the pressure bearing capacity, energy saving, and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Mix the water-absorbing resin and water at a mass ratio of 1:100 to make a freezing medium, and fill it into an acrylic tube with a diameter of 4cm. Since the tube is thin, no butter wall is used to shape it, but the collapse at both ends is obvious. Therefore, the filling is longer and consumes more freezing medium. Put the acrylic tube filled with the freezing medium into the refrigerator to freeze, and it has good sealing properties. It is measured that the pressure of the freezing medium is greater than 0.5MPa, and a good sealing effect is achieved.

Embodiment 2

[0059] Mix water-absorbent resin and water at a mass ratio of 1:100 to make a freezing medium, and fill it into a metal pipe with a diameter of 8 cm. In the initial operation, the butter wall was not used to set the shape. It was found that the freezing medium fell down due to its own gravity and could not fill the entire pipe diameter. Therefore, the first butter wall and the second butter wall were used to set the shape of the freezing medium, and the butter wall filled the entire pipe diameter with the freezing medium , Two sections of butter wall with a thickness of 4cm and a section of freezing medium with a thickness of 4cm are shaped in the middle of the two sections. After freezing in the refrigerator, the measured pressure is greater than 1.0MPa, achieving a good sealing effect.

Embodiment 3

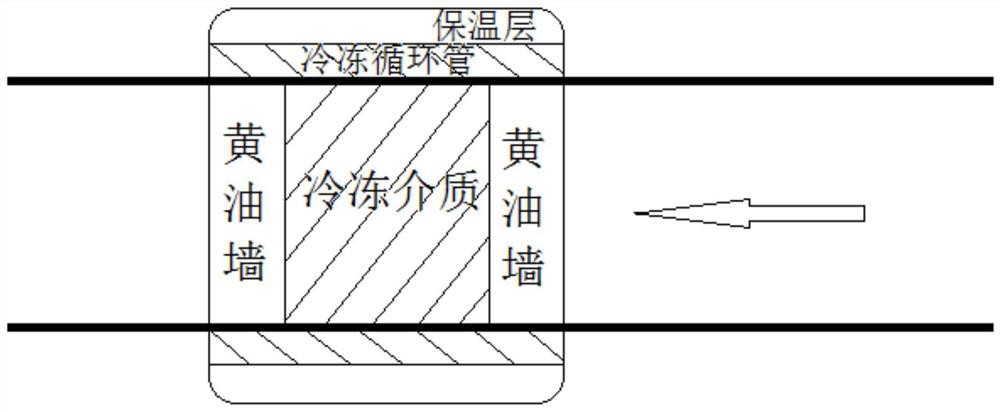

[0061] In the target oil and gas pipeline with a diameter of 20cm, first put a 10cm thick first butter wall at a distance of 40cm from the nozzle, and then put the freezing medium formed by immersing 40g of water-absorbing resin (50 mesh) into 4000g of water into the target oil and gas pipeline, and use 5cm The thick second wall of butter squeezes the freezing medium against the top of the target oil and gas pipeline. Among them, the outer wall of the target oil and gas pipeline is provided with a refrigerated circulation pipeline and a 5 cm thick insulation layer. The refrigeration equipment is turned on, and the circulating refrigerated liquid (water and ethylene glycol with a mass ratio of 1:1) freezes the refrigerated medium to expand and seal The target oil and gas pipeline has been measured to have a pressure greater than 1.0MPa, achieving a good plugging effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com