Temperature-control rigid expansion plugging working fluid for drilling fluid

A technology of drilling fluid and working fluid, which is applied in the direction of drilling composition, chemical instruments and methods, etc., and can solve the problems of narrow application range, complicated ball forming process, lack of fracture sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

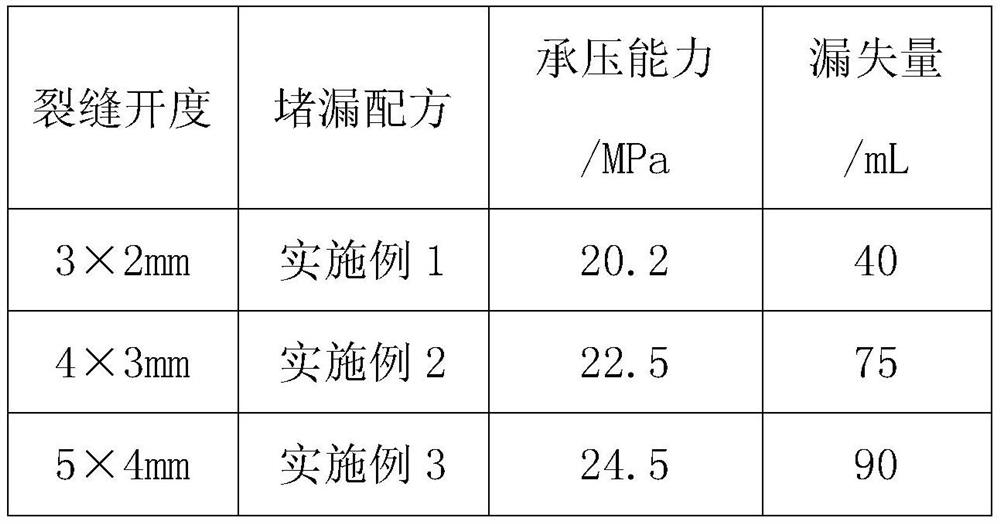

Embodiment 1

[0035] This embodiment provides a temperature-controlled rigid expansion plugging fluid system, which includes 100 parts of plugging base slurry (4% bentonite slurry + 0.4% CMC-HV + 0.3% DSP-II), 2 parts of shape memory Alloy-type temperature-controlled rigid expansion plugging agent (particle size 1.2-2.0mm, activation temperature 90°C), 3 parts shape-memory polymer-type temperature-controlled rigid expansion plugging agent (8-40 mesh, activation temperature 100°C), 10 parts Parts of rigid calcium carbonate plugging particles (10-160 mesh), 4 parts of elastic graphite plugging particles (20-80 mesh), 2 parts of mica flake material (20-80 mesh), 0.3% of polypropylene fiber material. The plugging base slurry was prepared in advance, and each plugging agent was added in sequence at a stirring rate of 6000r / min, and stirred evenly for 20 minutes.

Embodiment 2

[0037]This embodiment provides a temperature-controlled rigid expansion plugging fluid system, which includes 100 parts of plugging base slurry (4% bentonite slurry + 0.4% CMC-HV + 0.3% DSP-II), 3 parts of shape memory Alloy type temperature-controlled rigid expansion plugging agent (particle size 2.2-3.0mm, activation temperature 90°C), 5 parts of temperature-controlled rigid expansion plugging agent (8-40 mesh, activation temperature 100°C), 15 parts of rigid carbonic acid Calcium plugging particles (8-160 mesh), 6 parts of elastic graphite plugging particles (20-160 mesh), 3 parts of mica flake material (20-80 mesh), 0.3% of polypropylene fiber material. The plugging base slurry was prepared in advance, and each plugging agent was added in sequence at a stirring rate of 6000r / min, and stirred evenly for 20 minutes.

Embodiment 3

[0039] This embodiment provides a temperature-controlled rigid expansion plugging fluid system, which includes 100 parts of plugging base slurry (4% bentonite slurry + 0.4% CMC-HV + 0.3% DSP-II), 3 parts of shape memory Alloy type temperature-controlled rigid expansion plugging agent (particle size 2.2-3.0mm, activation temperature 90°C), 7 parts of temperature-controlled rigid expansion plugging agent (8-40 mesh, activation temperature 100°C), 18 parts of rigid carbonic acid Calcium plugging particles (8-160 mesh), 8 parts of elastic graphite plugging particles (20-160 mesh), 4 parts of mica flake material (20-80 mesh), 0.4 part of polypropylene fiber material. The plugging base slurry was prepared in advance, and each plugging agent was added in sequence at a stirring rate of 6000r / min, and stirred evenly for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com