Spar disc, seamless stone floor and preparation method of spar disc and seamless spar floor

A technology of seamless spar and disc, which is applied in the direction of architecture, building structure, floor, etc., can solve the problems that are not suitable for the small-area home improvement market, high professional requirements, and low standardization, and achieve superior performance, Easy to transport, good water resistance and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

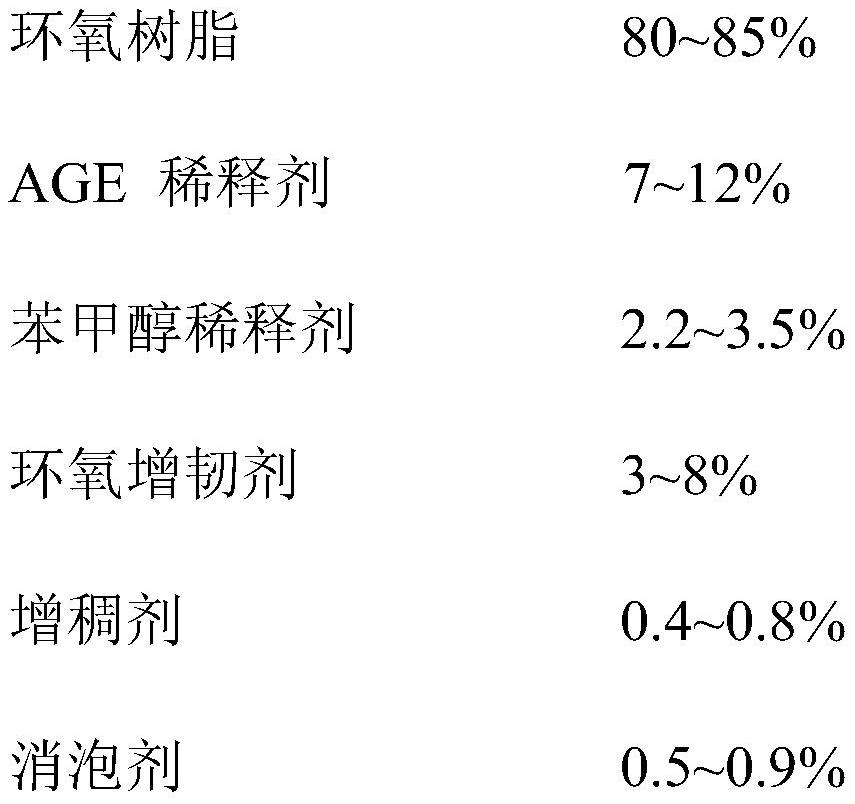

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares spar disc 1

[0035] Take the crystal sand particles and the resin adhesive according to the mass ratio of 10:1 and mix evenly, pour it into the disc mold with a standard thickness of 3mm, spread the cloth first, and then carry out plaster molding; , stand and solidify for 20 hours; then demould, and place for more than 24 hours; the disc is precisely cut according to the standard size, and the spar disc 1 is obtained.

[0036] In this embodiment, the crystal sand particles are colored quartz sand, that is, brightly colored quartz sand manufactured on the basis of natural quartz sand through dyeing. The Mohs hardness of colored quartz sand particles is greater than 5, and the particle size range is: 0.20mm to 2.0mm. The particle size range of its coarse particles is ≥1.2mm and ≤2.0mm, the particle size range of medium particles is <1.2mm and ≥0.4mm, and the particle size range of fine particles is <0.40mm and ≥0.20mm. The mass proportions of the ...

Embodiment 2

[0039] Embodiment 2 prepares spar disc 2

[0040] Take the crystal sand particles and the resin adhesive according to the mass ratio of 12:1 and mix evenly, pour it into the disc mold with a standard thickness of 6mm, spread the cloth flat first, and then carry out plaster molding; In a special oven, let stand to cure for about 3 hours; then remove the mold, place it at room temperature for further curing for more than 24 hours; cut the disc precisely according to the standard size, and obtain the spar disc 2 .

[0041]In this embodiment, the crystal sand particles are composed of four kinds of particles: colored quartz sand, natural quartz sand, ceramic sand and glass sand. The Mohs hardness of the particles is all greater than 5, and the particle size ranges from 0.20 mm to 3.0 mm. Among them, the coarse particle size range is ≥1.2mm and ≤3.0mm, and the coarse particles mainly use ceramic sand and glass sand, as well as a part of colored quartz sand, and the ratio of ceramic...

Embodiment 3

[0044] Embodiment 3 prepares spar disc 3

[0045] Take crystal sand particles and resin adhesive according to the mass ratio of 8:1 and mix evenly, pour it into a disc mold with a standard thickness of 2mm, spread the cloth flat, and then perform plastering and molding; then place it at room temperature 25-30℃ , stand and solidify for 20 hours; then demould, and place for more than 24 hours; the disc is precisely cut according to the standard size to obtain the spar disc 3 .

[0046] In this embodiment, the crystal sand particles are a combination of colored quartz sand and ceramic sand particles, the Mohs hardness of the particles is greater than 5, and the particle size ranges from 0.40mm to 1.2mm. The particles are a combination of colored quartz sand and ceramic sand, the ratio of the two combinations is 3:1, the particle size range of the medium particles is <1.2mm and ≥0.4mm; the fine particles are all colored quartz sand, and the particle size range is ≥0.2 mm and <0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com