Activated carbon as well as preparation method and application thereof

A technology of activated carbon and decay, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve problems such as low activity, poor performance, and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of gac, comprises the following steps:

[0030] After mixing spoiled biomass, waste textiles and water, ferment to obtain a blended fermentation product;

[0031] performing pyrolysis and carbonization on the blended fermentation product to obtain the activated carbon;

[0032] The temperature of the fermentation is 0-60° C., and the time is 0.1-50 h.

[0033] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0034] In the invention, after mixing spoiled biomass, waste textiles and water, fermentation is carried out to obtain a blended fermentation product; the temperature of the fermentation is 0-60° C., and the time is 0.1-50 hours.

[0035] In the present invention, the rotting biomass preferably includes one or more of rotting vegetables, rotting fruits and rotting hyperaccumulator plants; there is no speci...

Embodiment 1

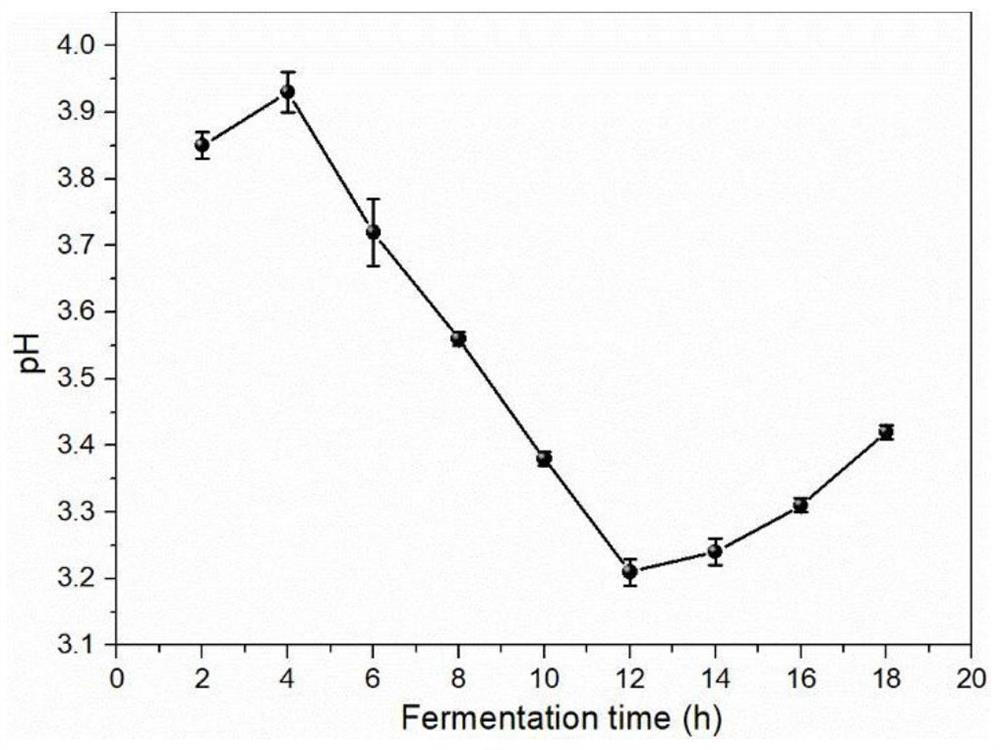

[0056] Crumble 100g of rotten apples into pulp and 10g of waste cotton cloth into an area of 0.1cm 2 After the lumps are stirred and mixed in a crushing mixer, the obtained blend is mixed with 15mL of water, and fermented in a clean fermenter, wherein the fermentation temperature is 25°C, and the fermentation time is 12h to obtain a blended fermentation product;

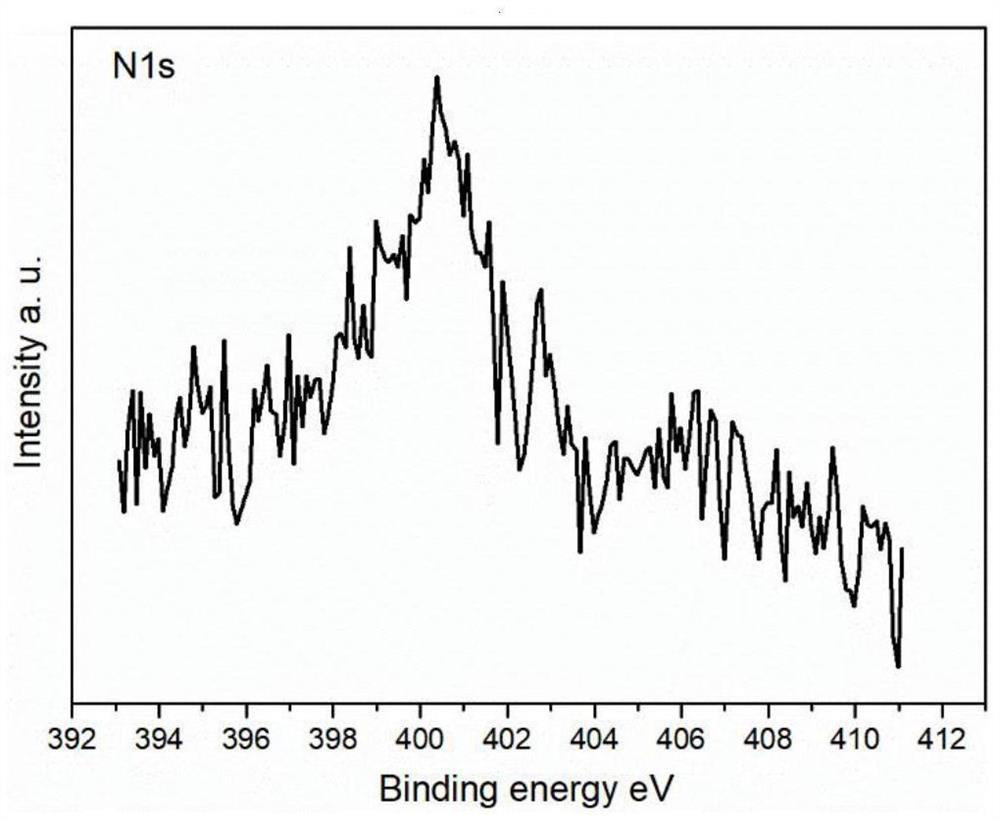

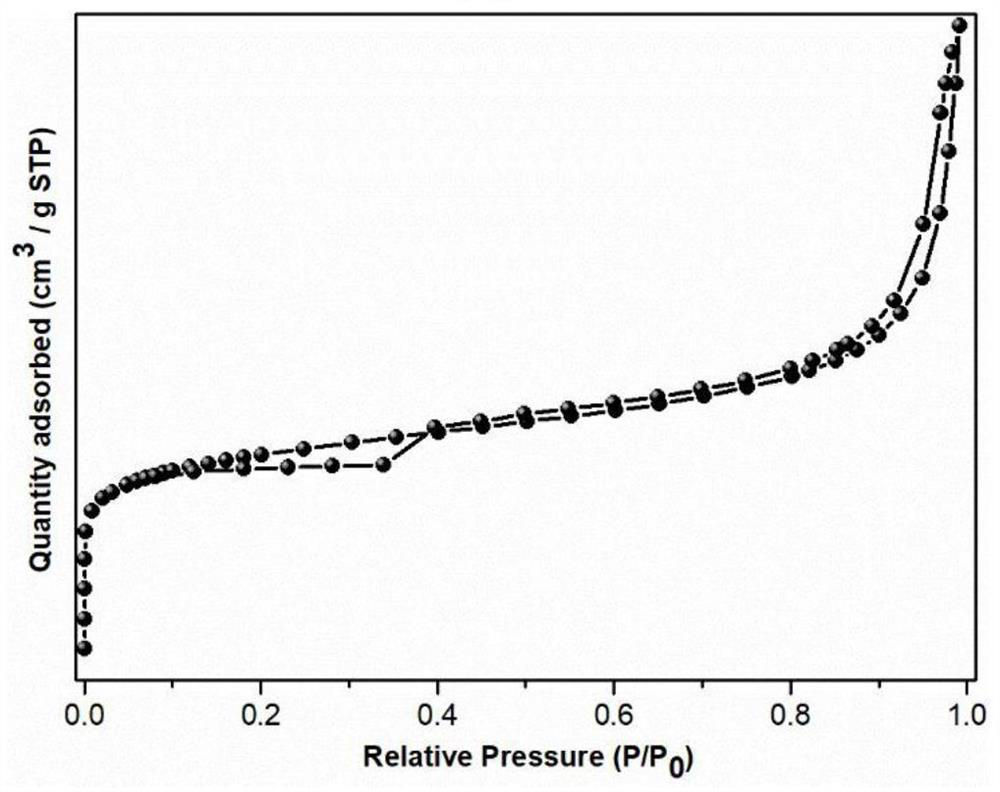

[0057] After the blended fermentation product was dried in a tube furnace (at a temperature of 105° C. for 24 h); in a nitrogen atmosphere, pyrolytic carbonization and ball milling were performed sequentially, wherein the temperature of pyrolytic carbonization was 600° C. The heating rate is 5°C / min, and the time is 2h; the ball milling time is 10h, the mass ratio of agate balls to materials is 80:1, and the rotating speed is 400r / min to obtain the activated carbon (referred to as DCP);

[0058] The gac described in 5mg is placed in 50mL cadmium ion concentration and is 50mg / L, in the solution that Congo red dyestu...

Embodiment 2

[0069] Crumble 100g of rotten lemon into pulp and 10g of waste cotton cloth into an area of 0.1cm 2 After the lumps are mixed by ball milling, the obtained blend is then mixed with 13mL of water, and fermented in a clean fermenter at a temperature of 30°C for 10 hours to obtain a blended fermented product;

[0070] After the blended fermentation product was dried in a tube furnace (at a temperature of 105° C. for 24 h); in a nitrogen atmosphere, pyrolytic carbonization and ball milling were carried out sequentially, wherein the temperature of pyrolytic carbonization was 700° C. The heating rate is 10°C / min, and the time is 2h; the ball milling time is 12h, the mass ratio of agate balls to materials is 100:1, and the rotating speed is 500r / min, to obtain the activated carbon;

[0071] The gac described in 5mg is placed in 50mL cadmium ion concentration and is 60mg / L, in the solution that Congo red dyestuff is 50mg / mL, after absorbing 48h under the condition of 25 ℃, cadmium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com