A kind of automatic control packaging machine and packaging method

A technology of packaging machine and packaging components, applied in the field of packaging, can solve the problems of single structure, inconvenient use, less design of discharging packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

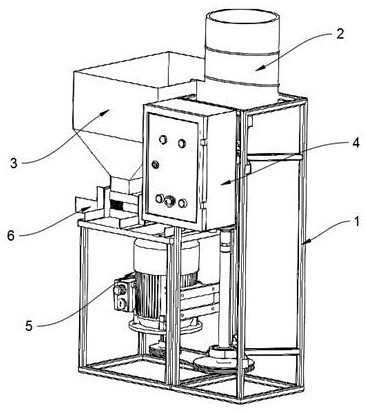

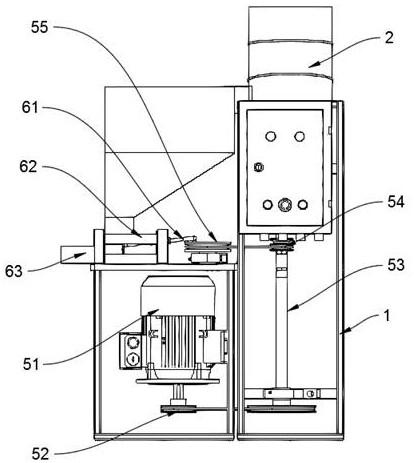

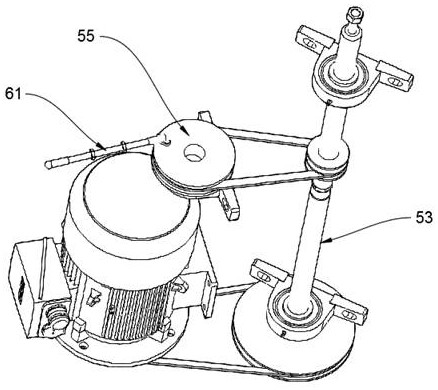

[0028] refer to figure 1 and figure 2 , a self-control packaging machine, including a bracket 1, a connecting pipe 2, a release funnel 3, an electric control box 4, a drive 5 and a packaging assembly 6, the outlet of the connecting pipe 2 and the feed of the release funnel 3 port connection, the packaging component 6 is arranged below the discharge port of the release funnel 3, after the material enters from the feed port of the connecting pipe 2, it is discharged from the discharge port of the connecting pipe 2 into the release funnel 3 , discharged from the discharge port of the release funnel 3, the packaging assembly 6 includes a carrier, a discharge rod and a discharge member 63, the material falls in the carrier, and the driving member 5 drives the discharge of the packaging assembly 6 The material rod pushes the material to be discharged from the discharge part 63, and enters the packaging bag or packaging box connected with the discharge part 63. The electric control...

Embodiment 2

[0032] refer to figure 1 and figure 2 , a self-control packaging machine, including a bracket 1, a connecting pipe 2, a release funnel 3, an electric control box 4, a drive 5 and a packaging assembly 6, the outlet of the connecting pipe 2 and the feed of the release funnel 3 port connection, the packaging component 6 is arranged below the discharge port of the release funnel 3, after the material enters from the feed port of the connecting pipe 2, it is discharged from the discharge port of the connecting pipe 2 into the release funnel 3 , discharged from the discharge port of the release funnel 3, the packaging assembly 6 includes a carrier, a discharge rod and a discharge member 63, the material falls in the carrier, and the driving member 5 drives the discharge of the packaging assembly 6 The material rod pushes the material to be discharged from the discharge part 63, and enters the packaging bag or packaging box connected with the discharge part 63. The electric control...

Embodiment 3

[0036] refer to figure 1 and figure 2 , a self-control packaging machine, including a bracket 1, a connecting pipe 2, a release funnel 3, an electric control box 4, a drive 5 and a packaging assembly 6, the outlet of the connecting pipe 2 and the feed of the release funnel 3 port connection, the packaging component 6 is arranged below the discharge port of the release funnel 3, after the material enters from the feed port of the connecting pipe 2, it is discharged from the discharge port of the connecting pipe 2 into the release funnel 3 , discharged from the discharge port of the release funnel 3, the packaging assembly 6 includes a carrier, a discharge rod and a discharge member 63, the material falls in the carrier, and the driving member 5 drives the discharge of the packaging assembly 6 The material rod pushes the material to be discharged from the discharge part 63, and enters the packaging bag or packaging box connected with the discharge part 63. The electric control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com