Special hob relief grinding device for numerical control lathe

A technology of CNC lathes and special devices, which is applied in the direction of grinding drive devices, grinding machine parts, grinding racks, etc., to achieve the effects of reducing the unbalanced load of the force, synchronizing the pitching movement, and conveniently balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

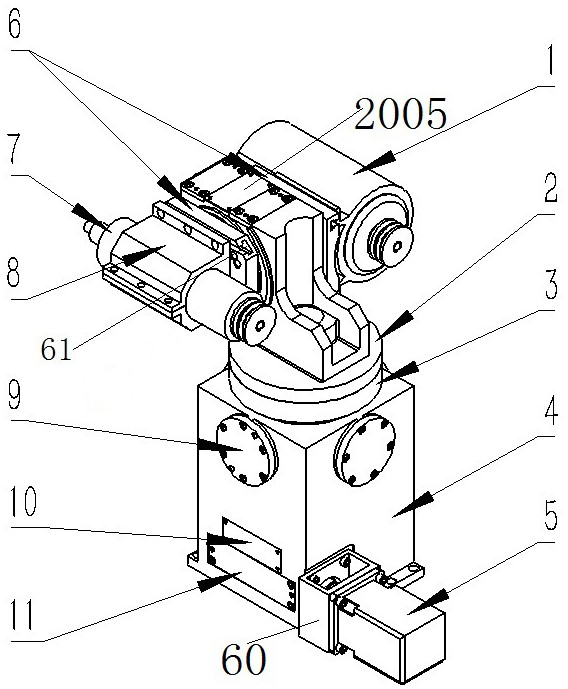

[0058] The special device 300 for hob relief grinding in this embodiment can be installed on the carriage 400 on the numerically controlled lathe. Cooperate with the knife and the workpiece to realize the relief grinding of the hob.

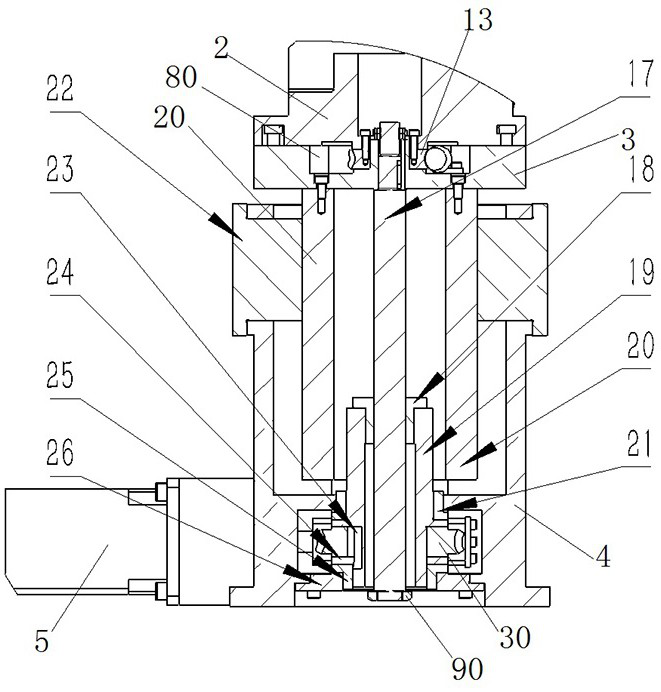

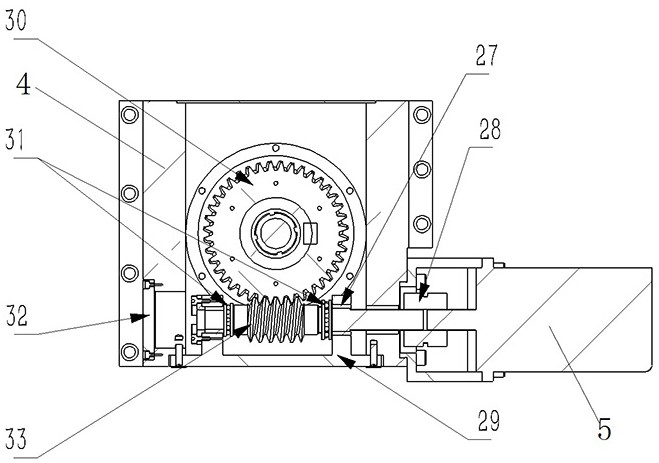

[0059] like Figure 1 to Figure 15 As shown, the hob shovel grinding special device 300 as a whole includes a base 4, a lifting platform 3, a rotary support 2 and a grinding head 7. The grinding head 7 is used to install the grinding wheel, and the lifting platform 3 is driven by a screw nut mechanism and can be assembled up and down. On the base 4, the rotary bracket 2 is rotatably mounted on the lifting platform 3 around the vertical axis, and can be lifted and lowered synchronously with the lifting platform 3. The grinding head 7 can be pitched and swung around the horizontal axis and mounted on the rotary bracket 2 to adjust the grinding. angle, the grinding head 7 rotates to perform corresponding relief grinding on the hob.

[0060] The sp...

specific Embodiment 2

[0090] It differs from Embodiment 1 mainly in that: in Embodiment 1, the lifting servo motor is located beside the base. In this embodiment, the lifting servo motor can be arranged under the base. At this time, the lifting worm gear mechanism can be omitted, and the lifting nut can be driven to rotate through the reduction gear mechanism to drive the lifting screw to move up and down.

specific Embodiment 3

[0092] It differs from Embodiment 1 mainly in that: in Embodiment 1, both the rotation adjustment mechanism and the pitch swing adjustment mechanism are worm and gear mechanisms, and a manual operating lever is configured to realize manual operation. In this embodiment, the manual operation lever is omitted, and all servo motors are configured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com