CNC multi-station machining auxiliary clamping jig

A multi-station and fixture technology, applied in the field of fixtures, can solve problems such as time-consuming, inconvenient clamping, and instability, and achieve the effects of ensuring product quality, reducing machine adjustment time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

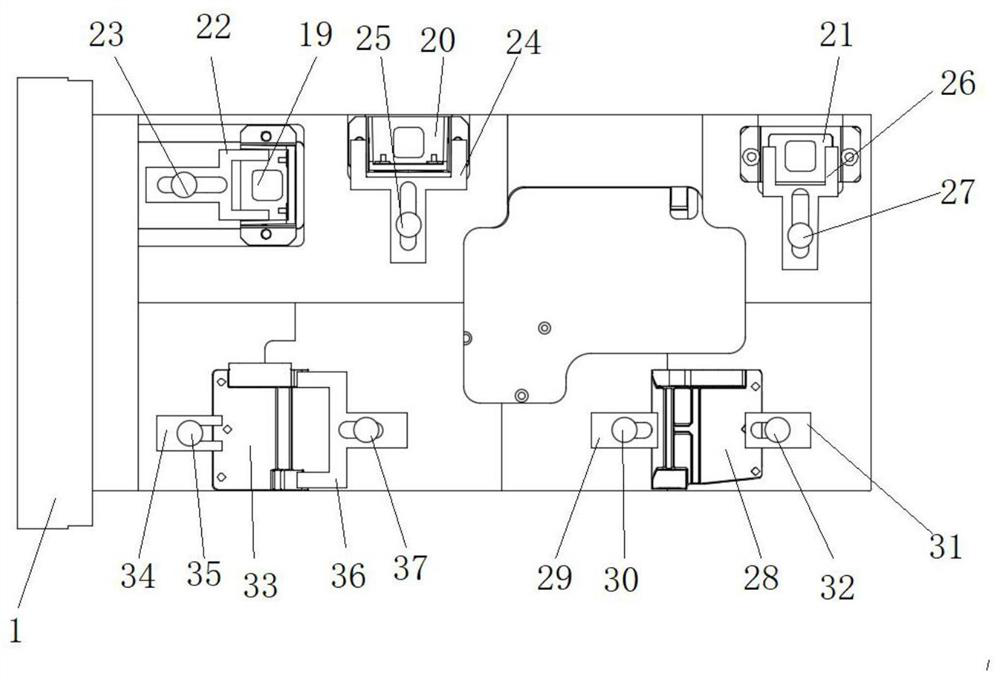

[0038] like figure 1 As shown, this embodiment provides a CNC multi-station machining auxiliary clamping fixture, which is used to install on the CNC constant speed axis to process the emission plate, the beam splitting prism seat, the horizontal axis motor seat and the vertical axis motor seat at the same time.

[0039] The auxiliary clamping fixture for CNC multi-station machining in this embodiment includes a vertical flange 1 and a multi-station horizontal fixing plate 2 .

[0040] One side of the vertical flange 1 is provided with a rectangular positioning chute 101, the central axis of the rectangular positioning chute 101 in the length direction coincides with the central axis of the vertical flange 1, and the side of the multi-station horizontal fixing plate 2 passes through the connecting piece 3 is fixed in the rectangular positioning chute 101, and the multi-station horizontal fixing plate 2 is provided with a fixture mechanism for fixing the launch plate, the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com