Comprehensive production process for tailing micro powder

A technology for tailings fine powder and production process, which is applied in dryers, grain processing, lighting and heating equipment, etc. The effect of long service life and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

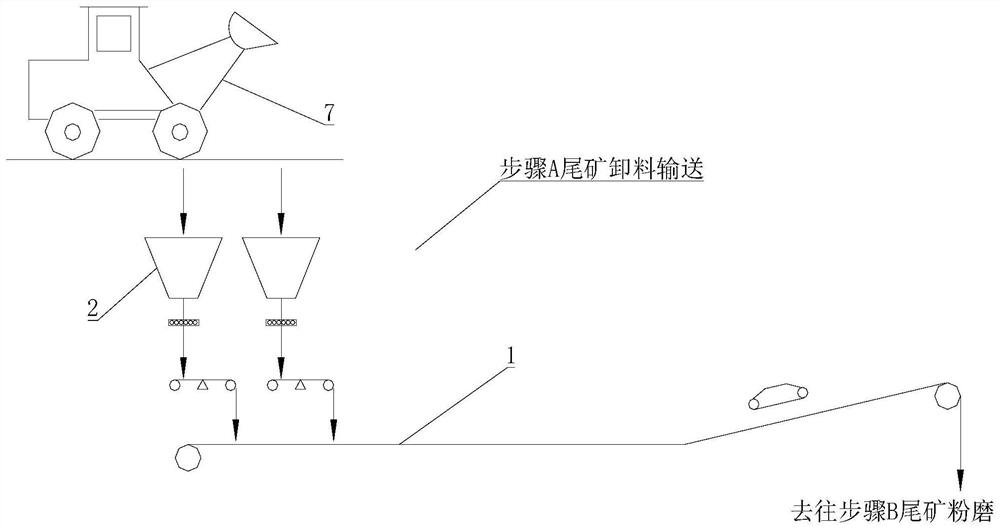

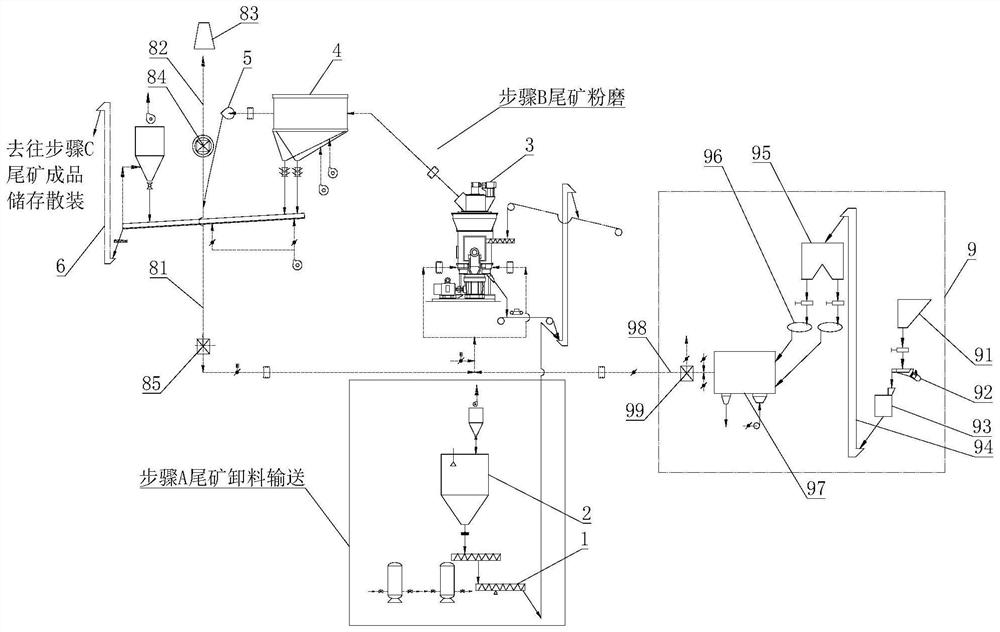

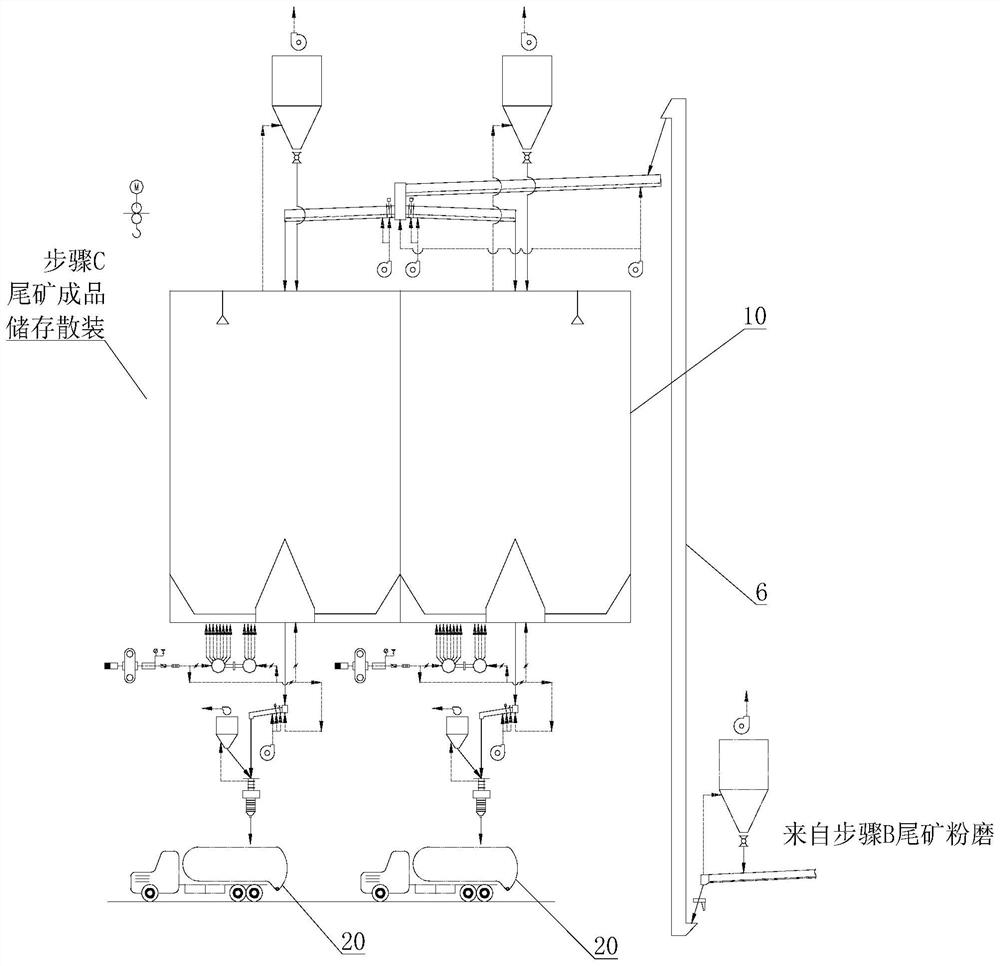

[0027] Such as Figure 1 to Figure 6As shown, in order to enable operators to efficiently utilize tailings to make tailings powder, the production process is efficient, reliable, and clean and environmentally friendly. Further, a comprehensive production process for tailings powder provided in this embodiment includes tailings Step A of unloading and conveying, step B of tailings grinding, and step C of bulk storage of finished tailings; in step A of unloading and conveying of tailings, the slag and slag in the tailings material are efficiently and reliably transported by the first pneumatic conveyor 1 In the tailings grinding step B, the vertical roller mill 3 is used to roll the tailings material into tailings powder, and the centrifugal fan 5 drives the air box pulse dust collector 4. Collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com