Surface Coated Cutting Tools

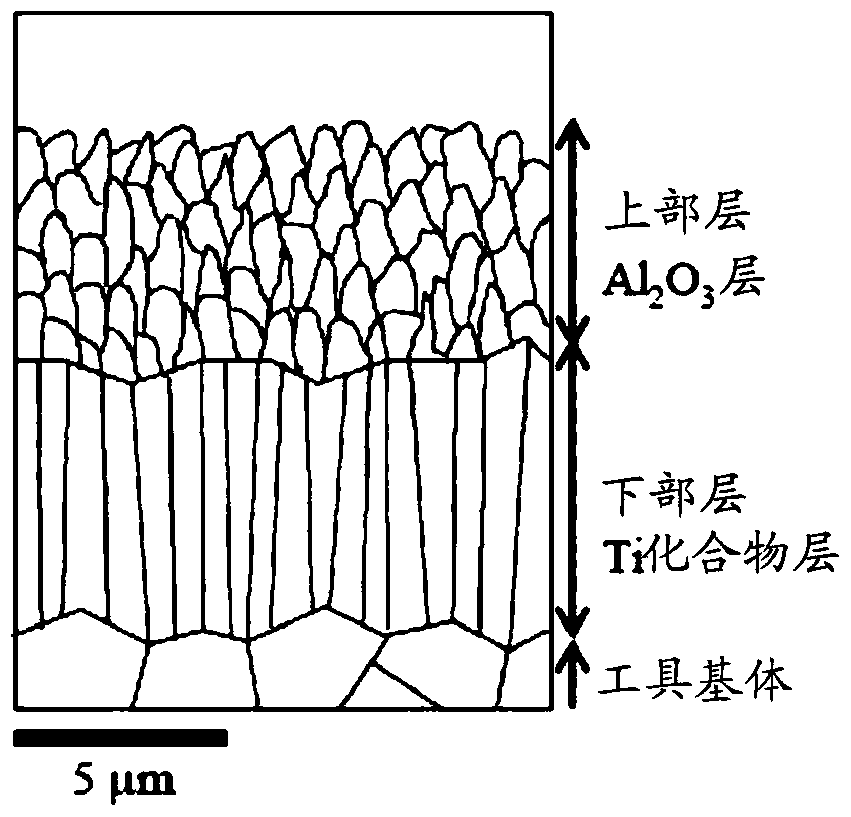

A cutting tool and surface coating technology, which is applied in the field of surface coating cutting tools, can solve problems such as insufficient adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

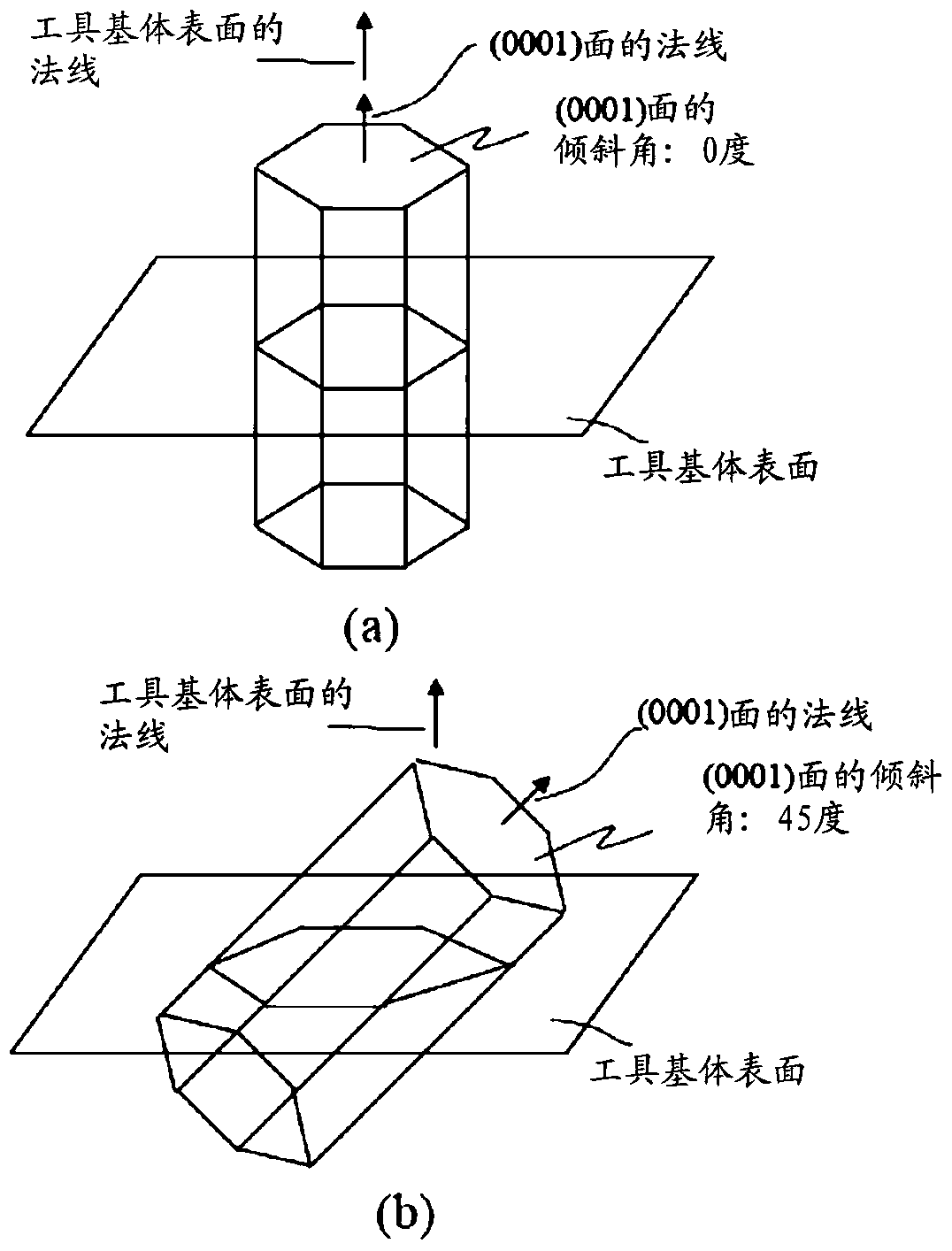

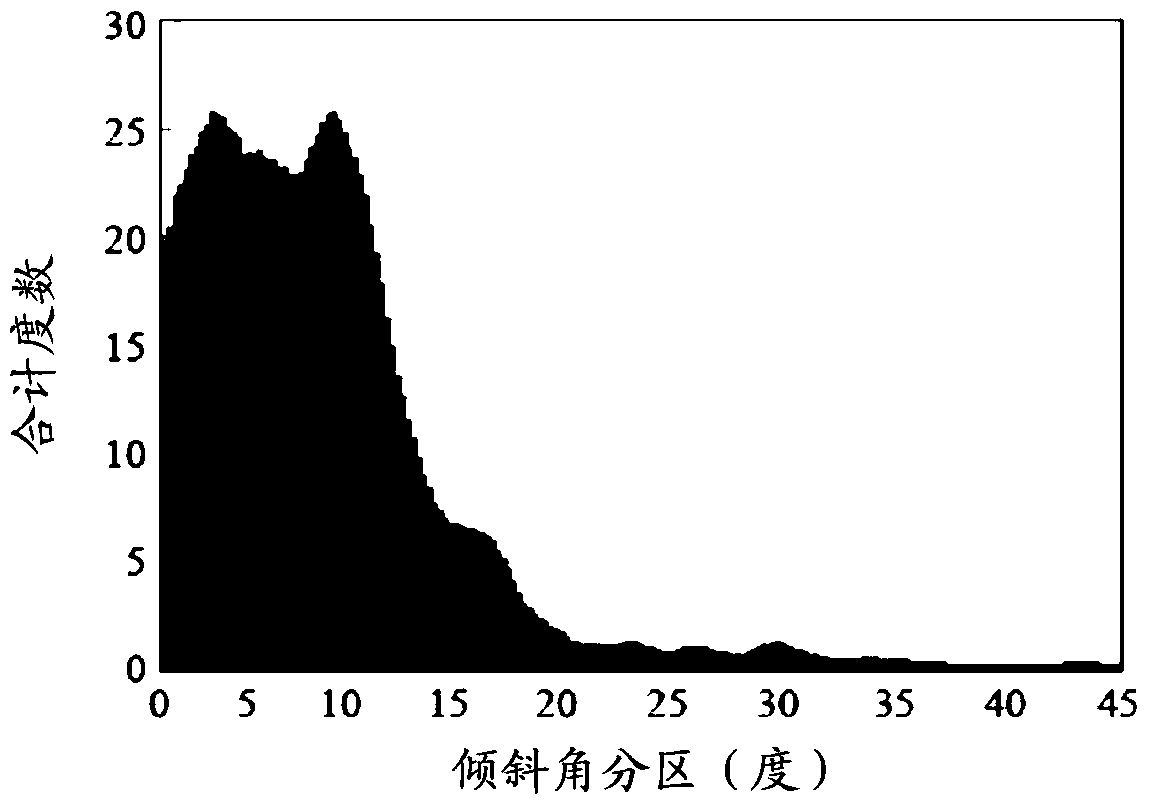

Method used

Image

Examples

Embodiment

[0076] As raw material powders, WC powder, TiC powder, ZrC powder, TaC powder, NbC powder, Cr 3 C 2 powder, TiN powder, and Co powder. These raw material powders are mixed with the compounding composition shown in Table 1, and paraffin wax is further added, and ball milled in acetone for 24 hours. In vacuum of 5 Pa, vacuum sintering is performed on the green compact at a predetermined temperature in the range of 1370-1470°C for 1 hour. After sintering, WC with the blade shape of ISO standard CNMG120408 is manufactured respectively. Carbide-based tool substrates A to E.

[0077] And, as the raw material powder, TiCN (TiC / TiN=50 / 50 in mass ratio) powder, ZrC powder, TaC powder, NbC powder, Mo 2 C powder, WC powder, Co powder and Ni powder, these raw material powders are blended with the composition shown in Table 2, wet mixed with a ball mill for 24 hours, after drying, they are stamped into compacts with a pressure of 98MPa, and pressed at 1.3kPa In a nitrogen atmosphere, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com