SCR (Selective Catalytic Reduction) flue gas denitration and dust removal device

A technology for denitrification, dust removal, and flue gas, applied in the field of flue gas denitrification, which can solve the problems of rising flue gas resistance and operating pressure difference, reducing denitration efficiency, and inability to fully react the flue gas, so as to improve the mixing speed and increase the contact area. , the effect of increasing the spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

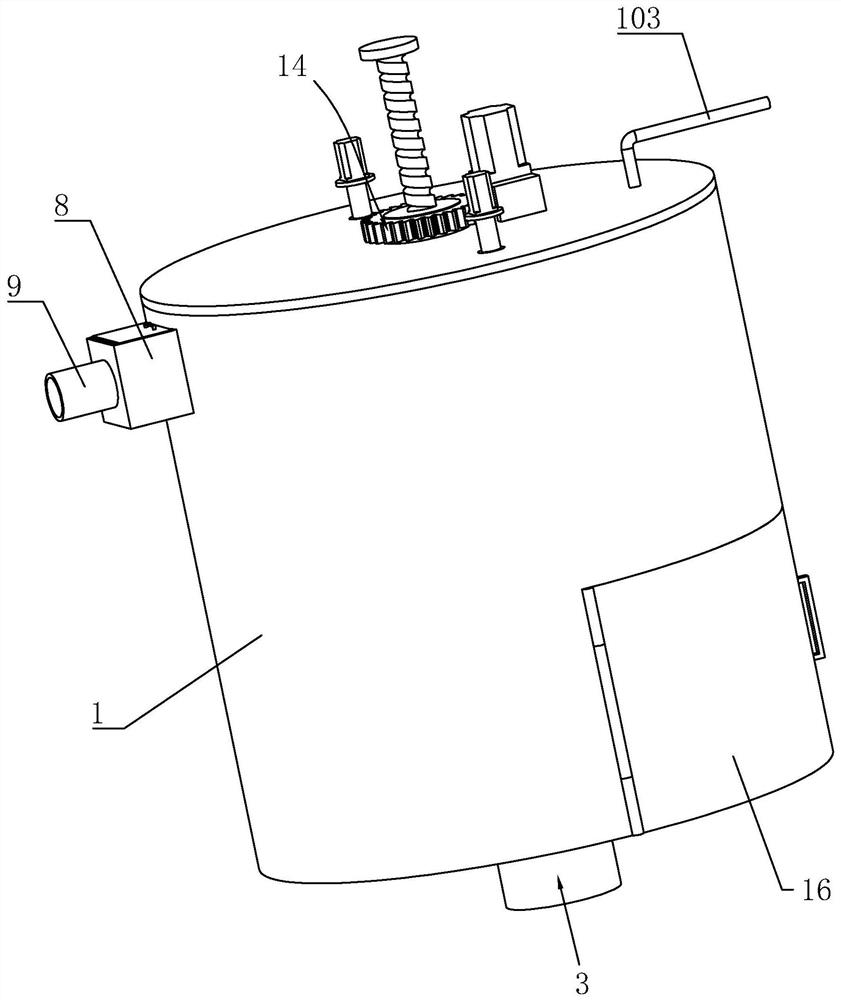

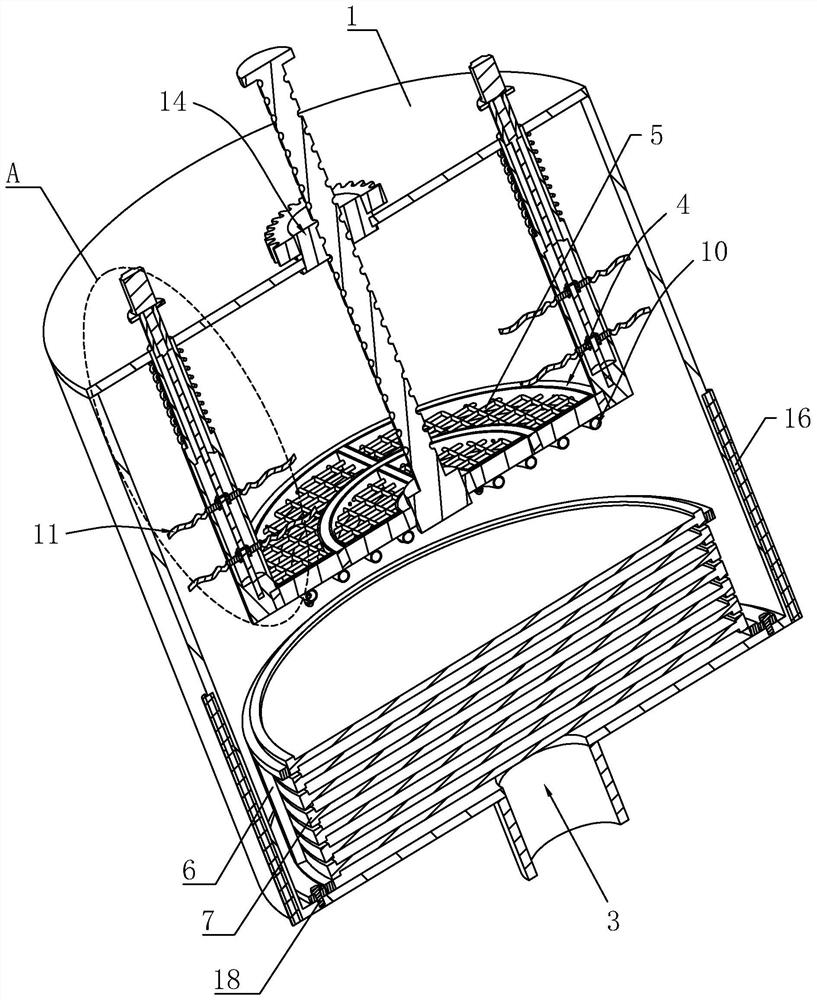

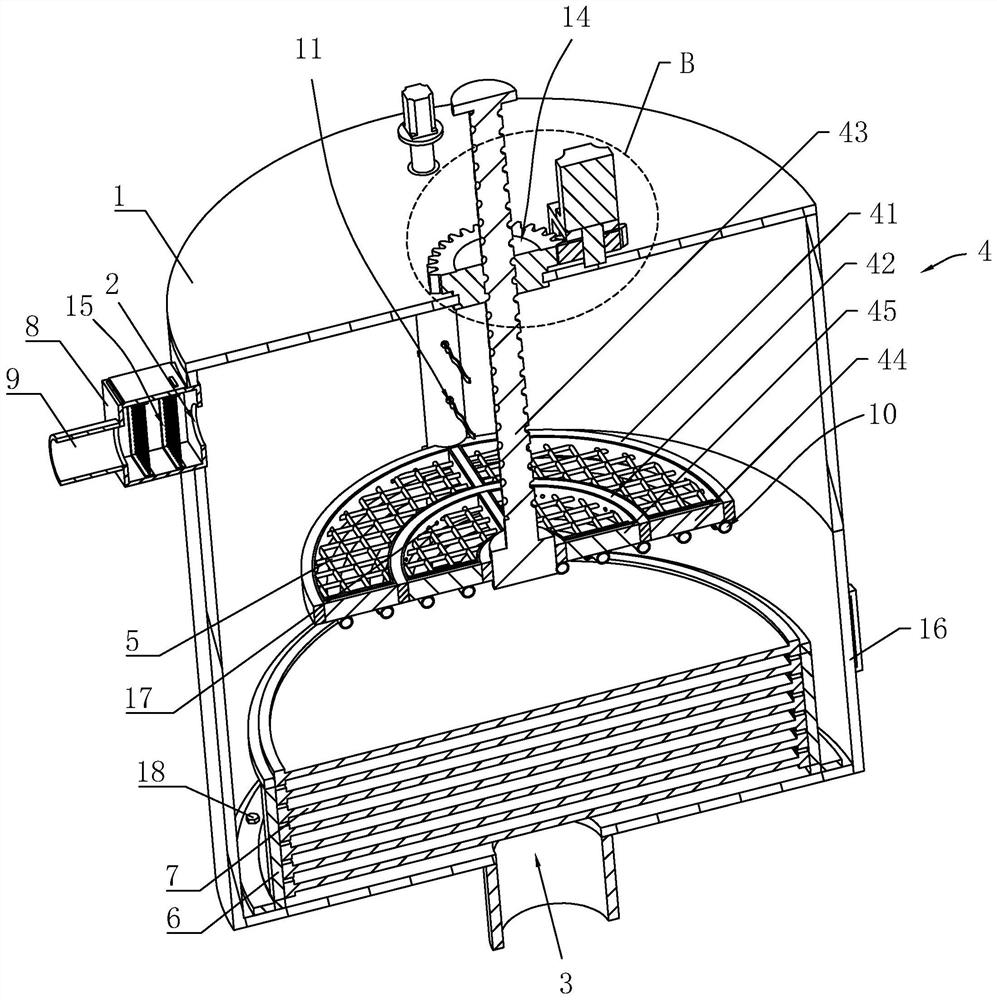

[0038] A kind of SCR flue gas denitrification and dust removal device, refer to figure 1 , including a tower body 1, the upper end of the side wall of the tower body 1 is provided with a smoke inlet 2, the bottom wall of the tower body 1 is provided with a smoke exhaust port 3, and the side wall of the tower body 1 is hingedly provided with a sealed door 16.

[0039] refer to figure 2 , the tower body 1 is provided with a ring frame 4, and some first plate catalysts 5 are installed on the ring frame 4, and a frame 6 is installed on the inner bottom wall of the tower body 1, and some second plate catalysts 7 are filled in the frame 6, and the ring frame The bottom of the tower 4 is provided with an ammonia injector 10, the top of the ring frame 4 is provided with a spoiler 11 for mixing ammonia and flue gas, and the top wall of the tower body 1 is provided with an adjustment assembly 14 for driving the ring frame 4 up and down.

[0040] During the flue gas treatment, firstly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com