Aluminum alloy supporting frame

A support frame, aluminum alloy technology, applied in display hangers, display shelves, medical science and other directions, can solve the problems of high risk factor, fire, support frame combustion, etc., to improve safety performance, improve the effect of flame retardant fire extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

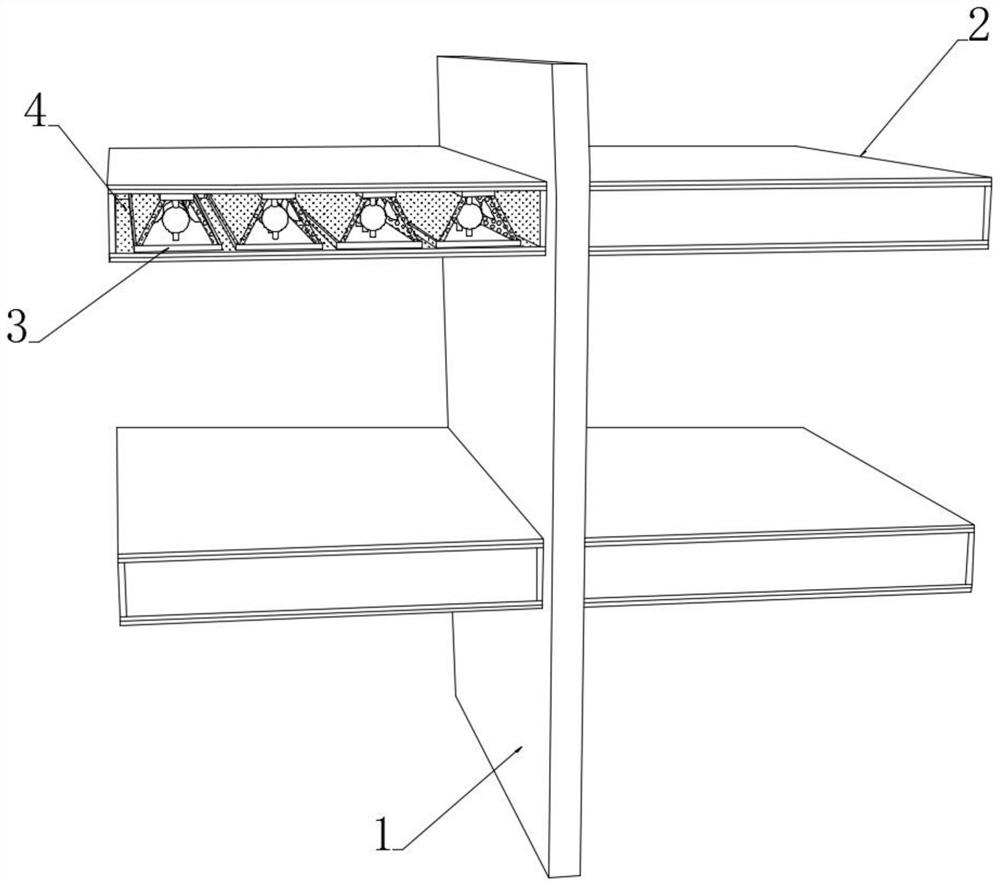

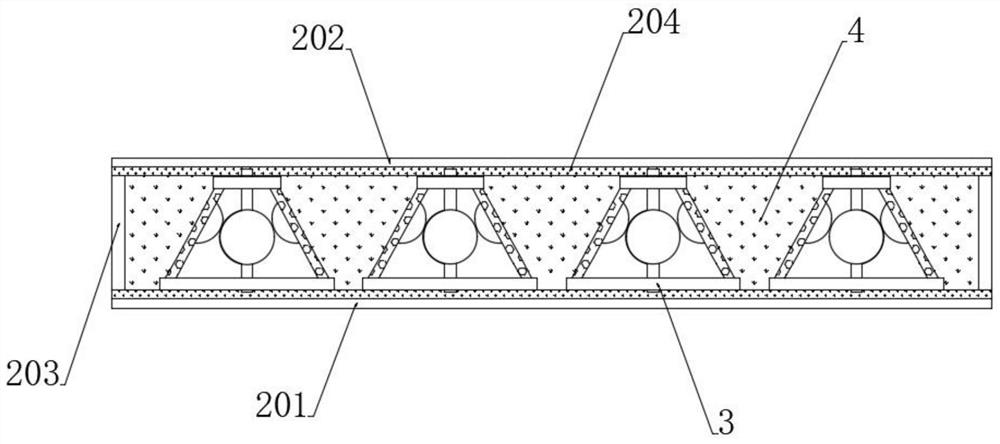

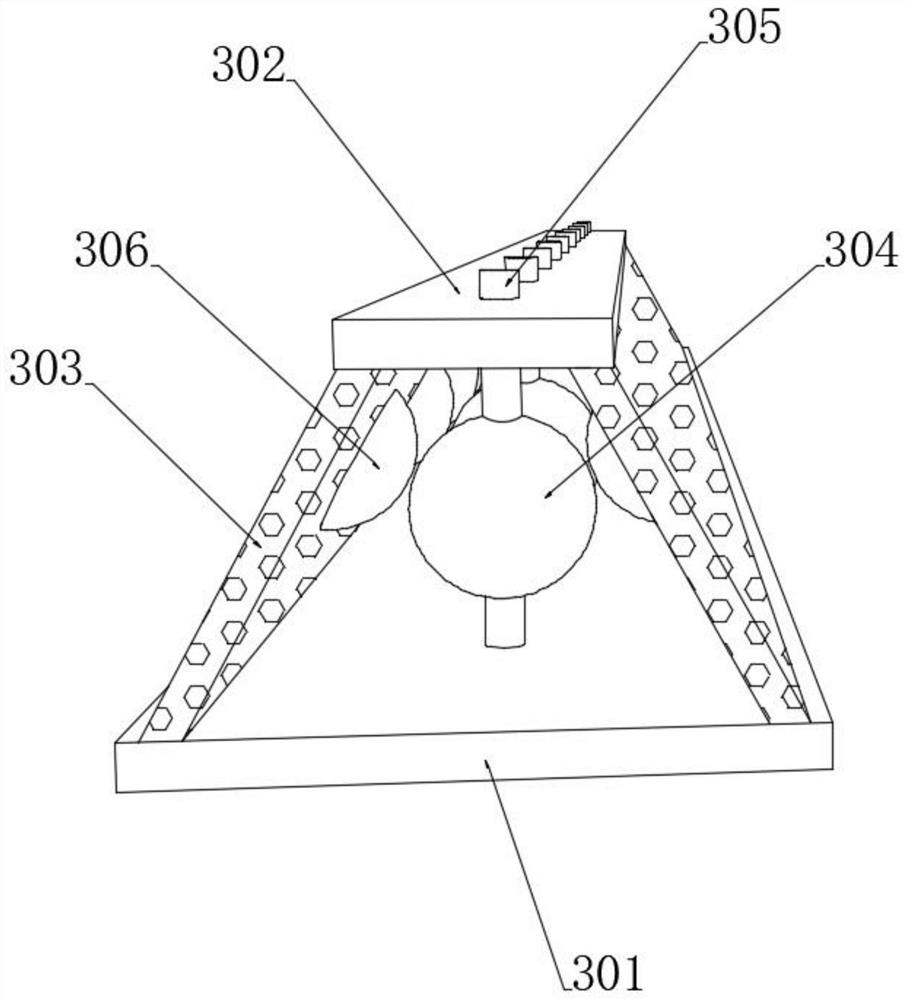

[0041] see Figure 1-3 , an aluminum alloy support frame, including a flame-retardant glass 1, a plurality of supporting plates 2 are distributed on the left and right side walls of the flame-retardant glass 1 along the vertical direction, and the supporting plate 2 includes a lower supporting surface 201 distributed up and down And the upper supporting surface 202, the opposite side walls of the lower supporting surface 201 and the upper supporting surface 202 are all attached with fireproof cotton 204, the lower supporting surface 201 and the upper supporting surface 202 are all provided with source extinguishing holes, and a pair of fireproof cotton 204 The opposite side walls of the edge are connected by the encapsulation panel 203, the lower support surface 201, the upper support surface 202 and the encapsulation panel 203 are all made of fire-resistant and flame-retardant materials, and the fire-resistant cotton 204 is made of flame-retardant and water-absorbing fiber mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com