Surface Acoustic Wave Device

A surface acoustic wave, high sound velocity technology, applied in the field of surface acoustic wave devices, can solve problems such as filter failure, inability to meet 5G high power requirements, and reduced durability, to improve withstand power, improve anti-electromigration ability, Avoid large drift effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] (1) Embodiment one

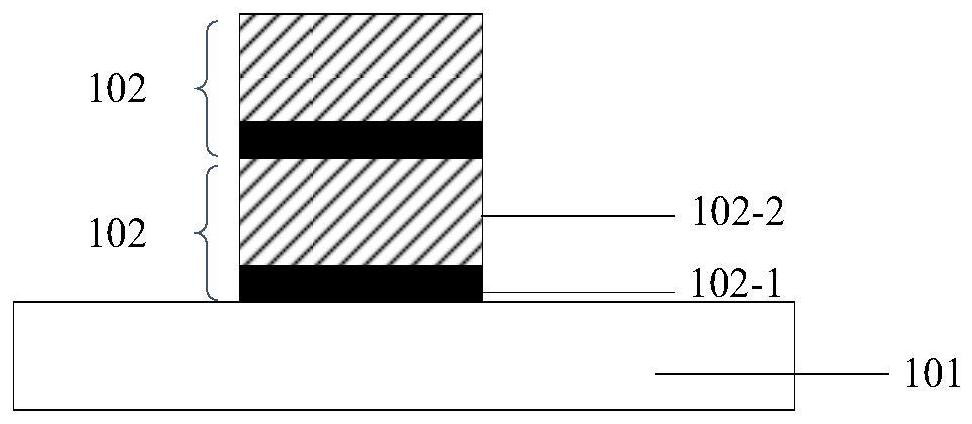

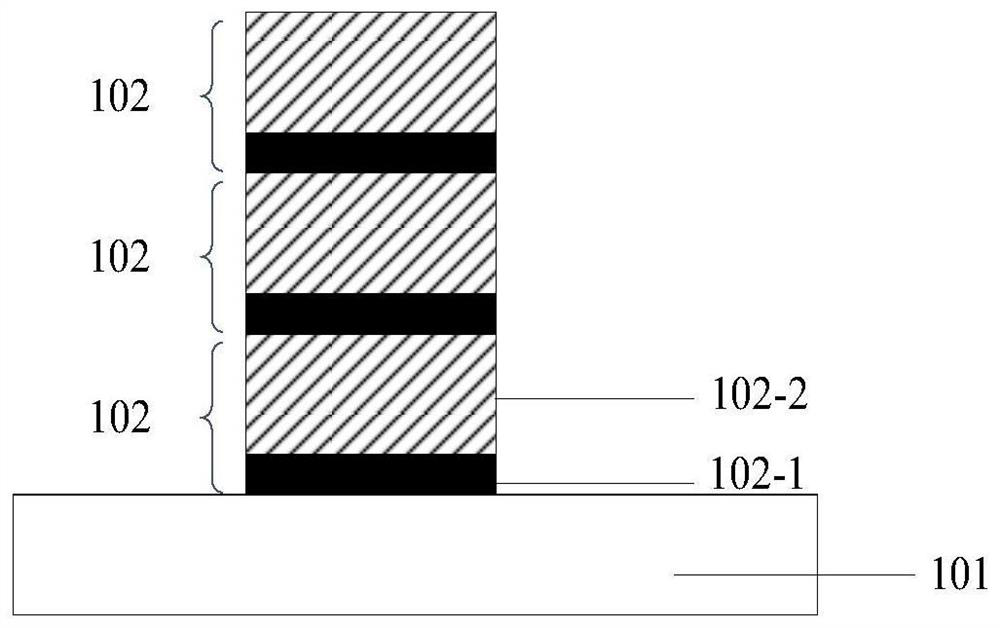

[0034] This embodiment provides a surface acoustic wave device, including a piezoelectric substrate 101 and an IDT electrode disposed on the piezoelectric substrate 101, the piezoelectric substrate can be quartz (SiO2), lithium niobate (LiNbO3) or lithium tantalate (LiTaO3 ) and other piezoelectric crystals. The IDT electrode includes a plurality of IDT electrode units 102 , and the plurality of IDT electrode units are stacked on the piezoelectric substrate 101 . figure 1 It shows that the IDT electrode includes two IDT electrode units 102 stacked, figure 2 A case where the IDT electrode includes three IDT electrode units 102 stacked is shown, but the present invention is not limited thereto.

[0035] Each IDT electrode unit includes a first buffer layer 102-1 disposed on the piezoelectric substrate and a first metal layer 102-2 disposed on the first buffer layer 102-1.

[0036] The first buffer layer 102-1 includes at least one of metal titaniu...

Embodiment 2

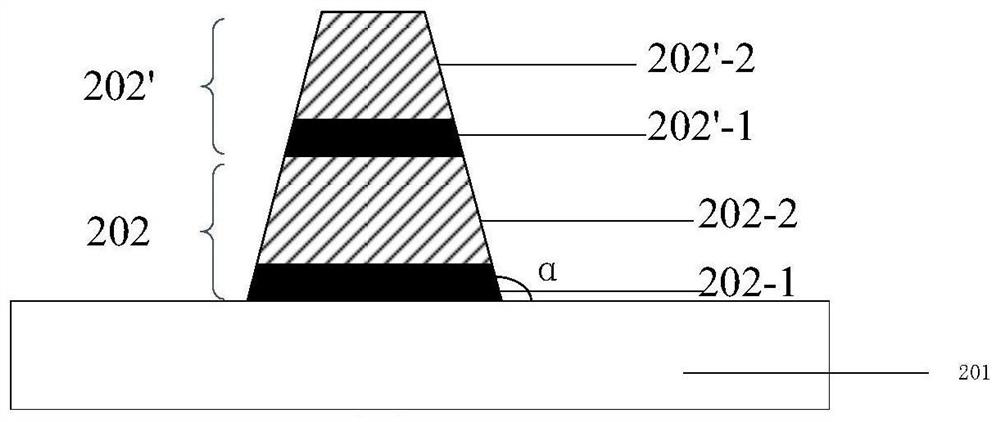

[0050] This embodiment provides a surface acoustic wave device, including a piezoelectric substrate 201 and an IDT electrode disposed on the piezoelectric substrate 201. The piezoelectric substrate can be quartz (SiO2), lithium niobate (LiNbO3) or lithium tantalate (LiTaO3 ) and other piezoelectric crystals. The IDT electrode includes a plurality of IDT electrode units 202 , and the plurality of IDT electrode units are stacked on the piezoelectric substrate 201 . image 3 It shows that the IDT electrode includes two IDT electrode units 202 stacked, Figure 4 A case where the IDT electrode includes three IDT electrode units 202 stacked is shown, but the present invention is not limited thereto. The arrangement of the IDT electrode units in this embodiment is the same as that in Embodiment 1.

[0051] The difference between this embodiment and the first embodiment is that the side of the IDT electrode is an inclined surface, and the angle α formed between the inclined surface ...

Embodiment 3

[0057] This embodiment provides a surface acoustic wave device, including a piezoelectric substrate 301 and an IDT electrode arranged on the piezoelectric substrate 301, the piezoelectric substrate can be quartz (SiO2), lithium niobate (LiNbO3) or lithium tantalate (LiTaO3 ) and other piezoelectric crystals. by Figure 5 As an example, in this embodiment, the IDT electrode includes two IDT electrode units, namely an IDT electrode unit 302 and an IDT electrode unit 302', the IDT electrode unit 302 is arranged on the piezoelectric substrate 301, and the IDT electrode unit 302' is arranged on The IDT electrode unit 302 is on the surface away from the piezoelectric substrate 301 .

[0058] The IDT electrode unit 302 includes a first buffer layer 302-1 disposed on the piezoelectric substrate and a first metal layer 302-2 disposed on the first buffer layer 302-1.

[0059] The first buffer layer 302-1 includes at least one of metal titanium or chromium, and when the wavelength of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com