Network structure ionic conductive adhesive as well as preparation method and application of ionic conductive adhesive

A technology of ion conduction and network structure, applied in the direction of structural parts, circuits, electrical components, etc., can solve problems such as difficulty in adapting to the challenges of negative electrode materials, and achieve the effects of low cost, good safety and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a network structure ion conductive adhesive, comprising the following steps:

[0032] Step 1, preparing a Pluronic aqueous solution, adding Pluronic to deionized water, stirring to dissolve it completely, and preparing a Pluronic aqueous solution with a mass concentration of 5%-30%;

[0033] Step 2, add acrylic acid monomer into deionized water, stir to dissolve it completely, and prepare an acrylic acid aqueous solution with a mass concentration of 25%-50%, and add lithium hydroxide powder to adjust the pH of the acrylic acid aqueous solution to 5-7; The mass ratio of body (AA) to Pluronic is (7-9): (1-3);

[0034] Step 3, adding an initiator into the acrylic acid solution, the initiator is a compound that is easily decomposed into free radicals, and is any one of ammonium persulfate or sodium metabisulfite, and the amount of the initiator is 0.05%- 2%;

[0035] Step 4, the temperature of the solution in which the acrylic acid and the initiator ...

Embodiment 1

[0050] Dissolve F127 and acrylic acid monomers in deionized water, prepare aqueous solutions with mass fractions of 5% and 30%, respectively, add lithium hydroxide powder to adjust the pH of the acrylic acid aqueous solution to 5, and add 0.1 wt% of acrylic acid monomers to the acrylic acid aqueous solution ammonium persulfate initiator; heat the acrylic acid solution containing the initiator to 80°C, add F127 aqueous solution dropwise, and react under nitrogen protection and magnetic stirring. The reaction temperature is kept at 80°C. After the reaction is carried out for 1 hour, the reaction ends. Wherein, the mass ratio of acrylic acid monomer and F127 is 9:1. Adhesive A1 was thus prepared.

[0051] The synthesized binder A1 was used to prepare the nano-silicon negative electrode of the lithium ion battery, and all the steps were the same as in Comparative Example 1, except that the binder used in the preparation of the slurry was the synthesized binder A1.

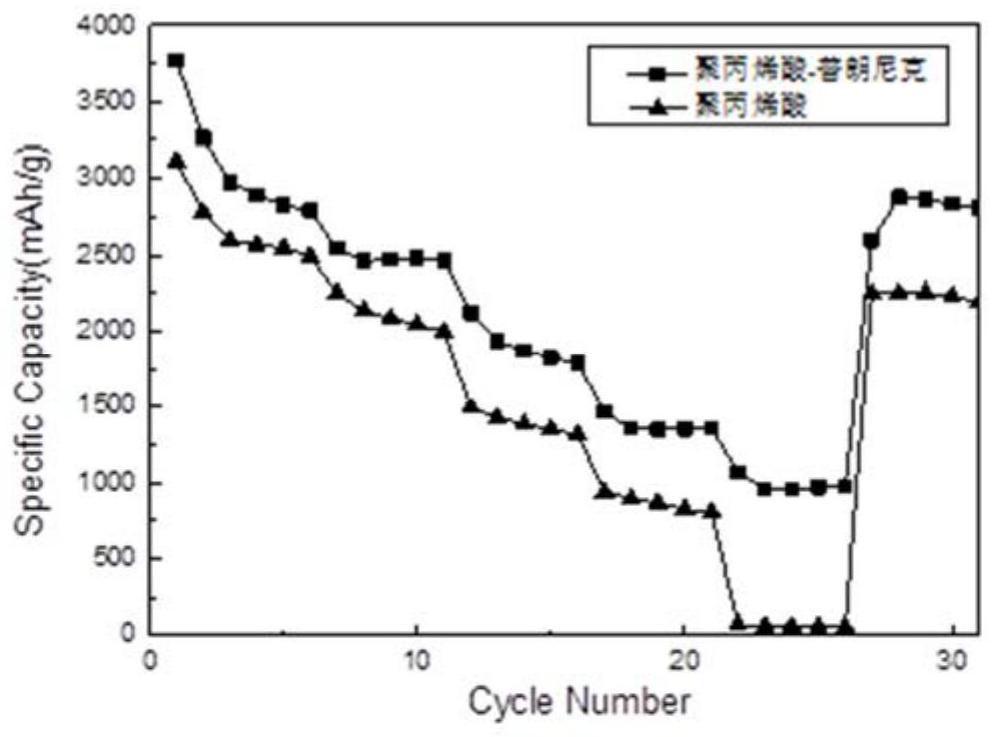

[0052] The li...

Embodiment 2

[0054] Synthesize the ion-conductive polyacrylic acid-Pluronic adhesive A1 with network structure, and all steps are the same as in Example 1.

[0055] The synthetic network structure ion-conductive binder A1 was used to prepare the nano-silicon-carbon negative electrode of the lithium-ion battery. All the steps were the same as in Comparative Example 2, except that the binder used in the preparation of the slurry was the synthesized binder A1.

[0056] A lithium-ion battery assembled with a silicon-carbon negative electrode prepared by using the network structure ion-conductive binder A1 was tested, and all steps were the same as in Comparative Example 2.

[0057] Depend on figure 2 It can be seen that the adhesive is used in lithium-ion batteries, and the electrode sheets before and after the cycle can show that the electrode sheets still maintain good integrity after 100 cycles of recycling, which can more intuitively explain that the adhesive has good performance in lithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com