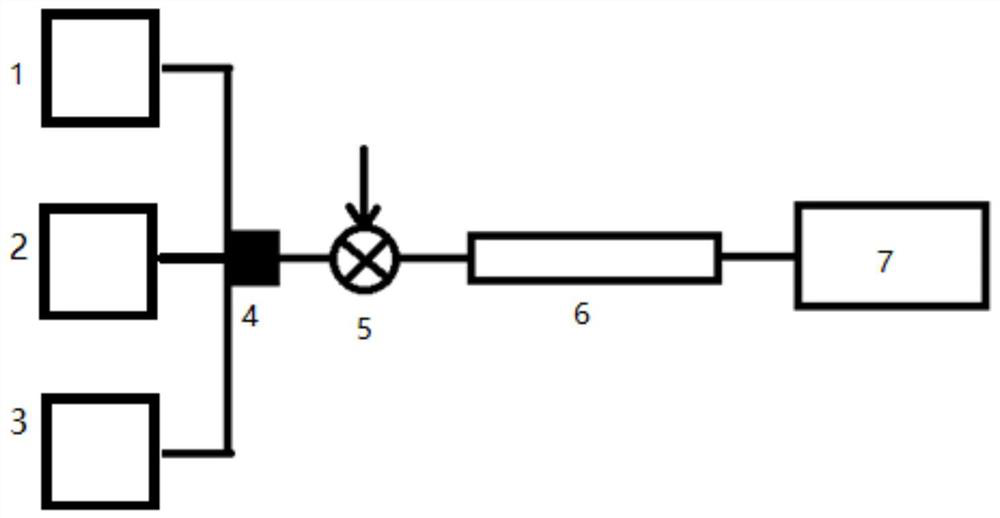

Dual gradient system in liquid chromatography and matched elution program setting method thereof

A liquid chromatography and gradient technology, which is applied in the field of instrument analysis, can solve the problems of being unable to be eluted and replaced, and the effective bonding sites gradually decrease, and achieve the requirements of low hardware requirements, wide range of strength changes, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

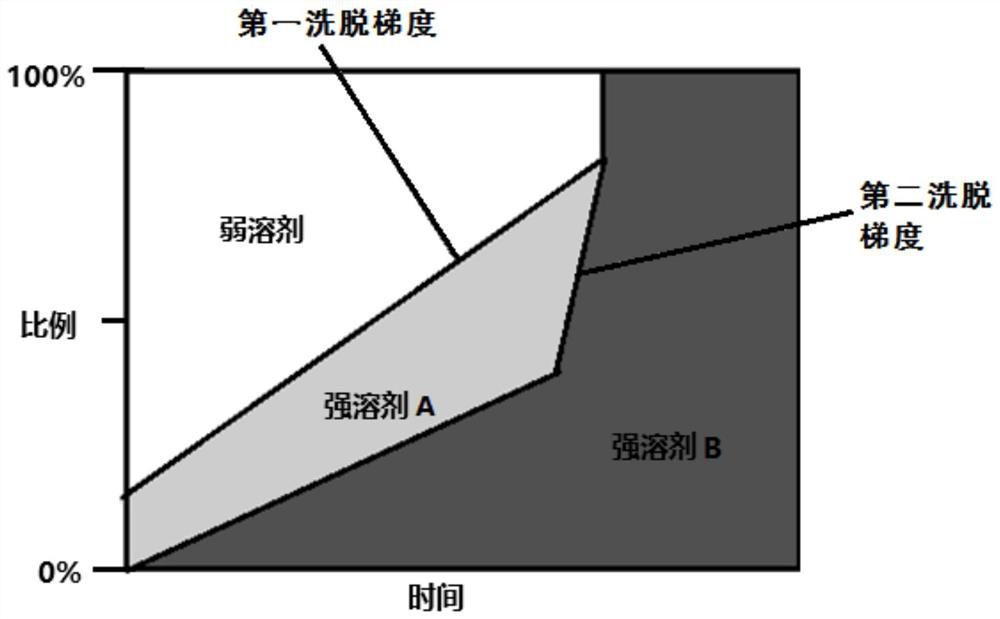

[0055] In the dual gradient system of this embodiment, the liquid phase combination pump uses two pumps, one pump directly pumps the weak solvent water, and the other pump has a built-in gradient proportional valve to pump the strong solvent A acetonitrile and the strong solvent B isopropanol respectively , wherein the elution capacity of isopropanol is much higher than that of acetonitrile; the separation column is a C18 column of Shimadzu.

[0056] As a comparison, in this embodiment, the system is used to separate the same group of targets in normal mode and dual gradient mode. The common mode does not use a double elution gradient, and the weak elution solvent used is water, and the strong solvent is acetonitrile; A super strong elution solvent isopropanol was used.

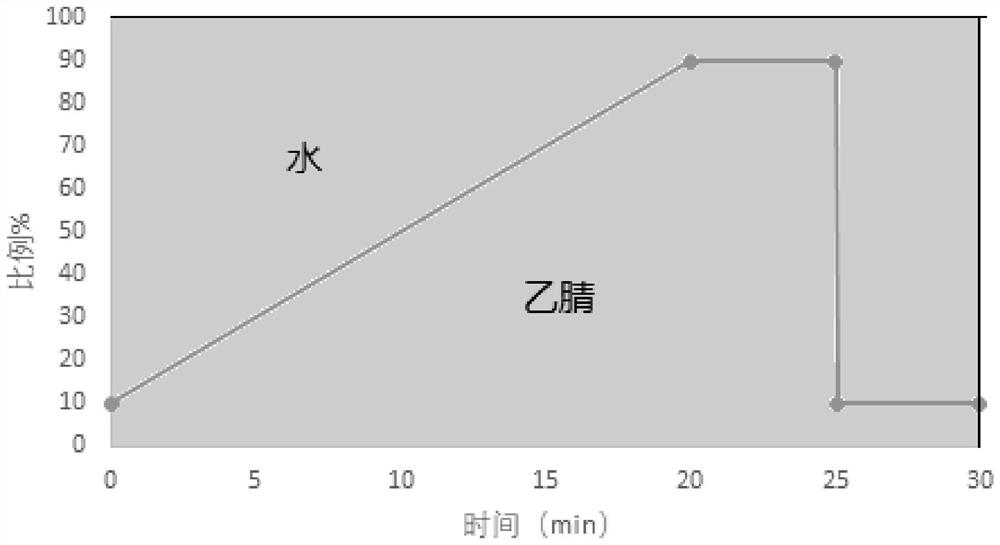

[0057] The gradient elution program of normal mode without double elution gradient is as follows: image 3 Shown, the total flow velocity of described liquid phase combination pump pumping solvent is 0.4mL / ...

Embodiment 2

[0061] In the dual gradient system of this embodiment, the liquid phase combination pump uses two pumps, one pump directly pumps the weak solvent water, and the other pump has a built-in gradient proportional valve to pump the strong solvent A acetonitrile and the strong solvent B isopropanol respectively , wherein the elution capacity of isopropanol is much higher than that of acetonitrile; the separation column is the T3 column of WATERS.

[0062] As a comparison, in this embodiment, the system is used to separate the same group of targets in normal mode and dual gradient mode. The common mode does not use a double elution gradient, and the weak elution solvent used is water, and the strong solvent is acetonitrile; A super strong elution solvent isopropanol was used.

[0063] The gradient elution program and conditions of the common mode in this embodiment are the same as those of Example 1, and the gradient elution program and conditions of the dual gradient mode of this e...

Embodiment 3

[0066] In the dual gradient system of this embodiment, the liquid phase combination pump uses two pumps, one pump directly pumps the weak solvent water, and the other pump has a built-in gradient proportional valve to pump the strong solvent A acetonitrile and the strong solvent B isopropanol respectively , wherein the elution capacity of isopropanol is much higher than that of acetonitrile; the separation column is a C18 column of Shimadzu.

[0067] As a comparison, in this embodiment, the system is used to separate the same group of targets in normal mode and dual gradient mode. The common mode does not use a double elution gradient, and the weak elution solvent used is water, and the strong solvent is acetonitrile; A super strong elution solvent isopropanol was used.

[0068] The gradient elution program and conditions of the common mode in this embodiment are the same as those of Example 1, and the gradient elution program and conditions of the dual gradient mode of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com