Method for preparing strontium fluoride crystal

A technology of strontium fluoride and crystals, which is applied in the field of biomimetic preparation of strontium fluoride crystals, can solve problems such as high cost, high energy consumption, and complicated process, and achieve the effects of simple operation, low energy consumption, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

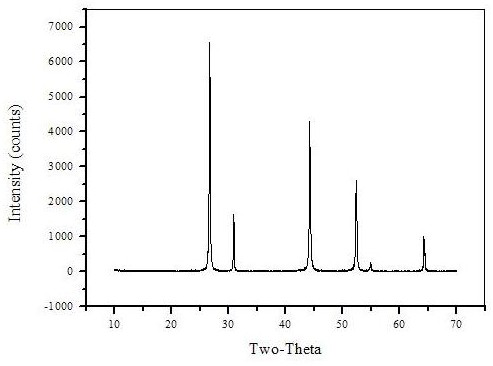

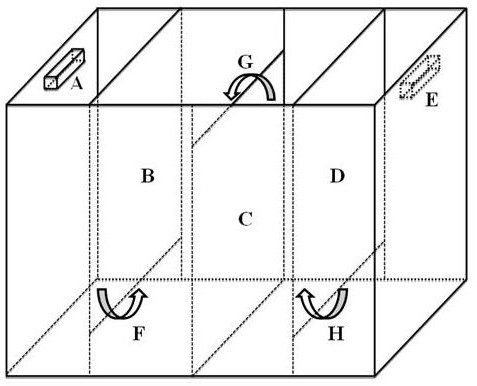

Embodiment 1

[0013] In the connected reaction device with 2 left and right ear grooves and 3 left, middle and right barrier plates, according to the molar ratio, strontium: fluorine = 1: 2.15, strontium chloride was added to the left ear groove, and ammonium fluoride was added to the left ear groove. in the right ear slot. Then, it is 0.15% glycine solution that contains mass ratio ratio concentration to add in the connected reactor, makes the liquid level of glycine solution higher than left ear groove and right ear groove upper edge 1cm, to guarantee the reaction in left ear groove, right ear groove The substances are connected through the mixture solution. Put the lid on the connected reactor, and let it stand for 7 days to react. The product was filtered, washed, and dried at 105°C for 1 h to obtain strontium fluoride crystals. The yield of strontium fluoride crystals was 99.5%, and the purity was 99.6%.

Embodiment 2

[0015] In the connected reaction device with 2 left and right ear grooves and 3 left, middle and right barrier plates, according to the molar ratio, strontium: fluorine = 1: 2.10, strontium chloride was added to the left ear groove, and ammonium fluoride was added to the left ear groove. in the right ear slot. Then, it is 0.10% glycine solution that contains mass ratio specific concentration to add in the connected reactor, makes the liquid level of glycine solution higher than left ear groove and right ear groove upper edge 1cm, to guarantee the reaction in left ear groove, right ear groove The substances are connected through the mixture solution. Put the lid on the connected reactor, and let it stand for 7 days to react. The product was filtered, washed, and dried at 105°C for 1 h to obtain strontium fluoride crystals. The yield of strontium fluoride crystals was 99.0%, and the purity was 99.9%.

Embodiment 3

[0017] In the connected reaction device with 2 left and right ear grooves and 3 left, middle and right barrier plates, according to the molar ratio, strontium: fluorine = 1: 2.20, strontium chloride was added to the left ear groove, ammonium fluoride was added to in the right ear slot. Then, it is 0.20% glycine solution that contains mass ratio specific concentration to add in the connected reactor, make the liquid level of glycine solution be higher than left ear groove and right ear groove upper edge 1cm, to guarantee the reaction in left ear groove, right ear groove The substances are connected through the mixture solution. Put the lid on the connected reactor, and let it stand for 7 days to react. The product was filtered, washed, and dried at 105°C for 1 h to obtain strontium fluoride crystals. The yield of strontium fluoride crystals was 99.9%, and the purity was 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com