Preparation method for porous carbon modified ferric sodium pyrophosphate/carbon positive electrode material of sodium ion battery

A technology for sodium ferric phosphate pyrophosphate and sodium ion batteries, which is applied in the preparation/purification of carbon, battery electrodes, secondary batteries, etc. It can solve the problems of low electronic conductivity, achieve good rate performance, inhibit crystal growth, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

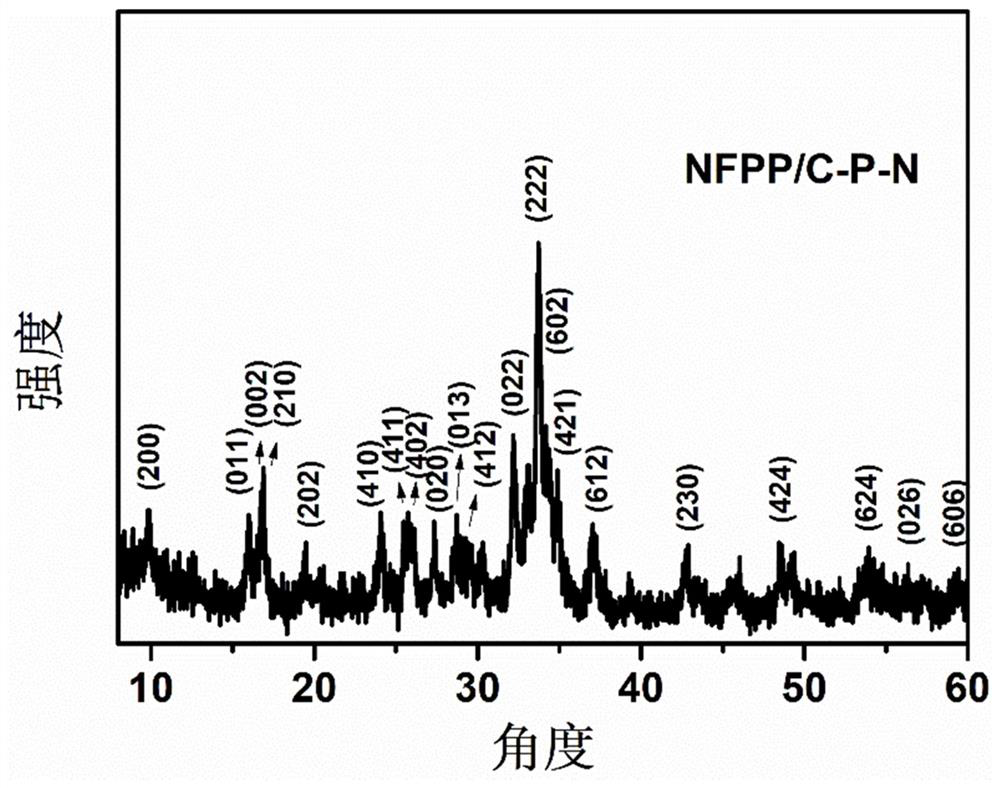

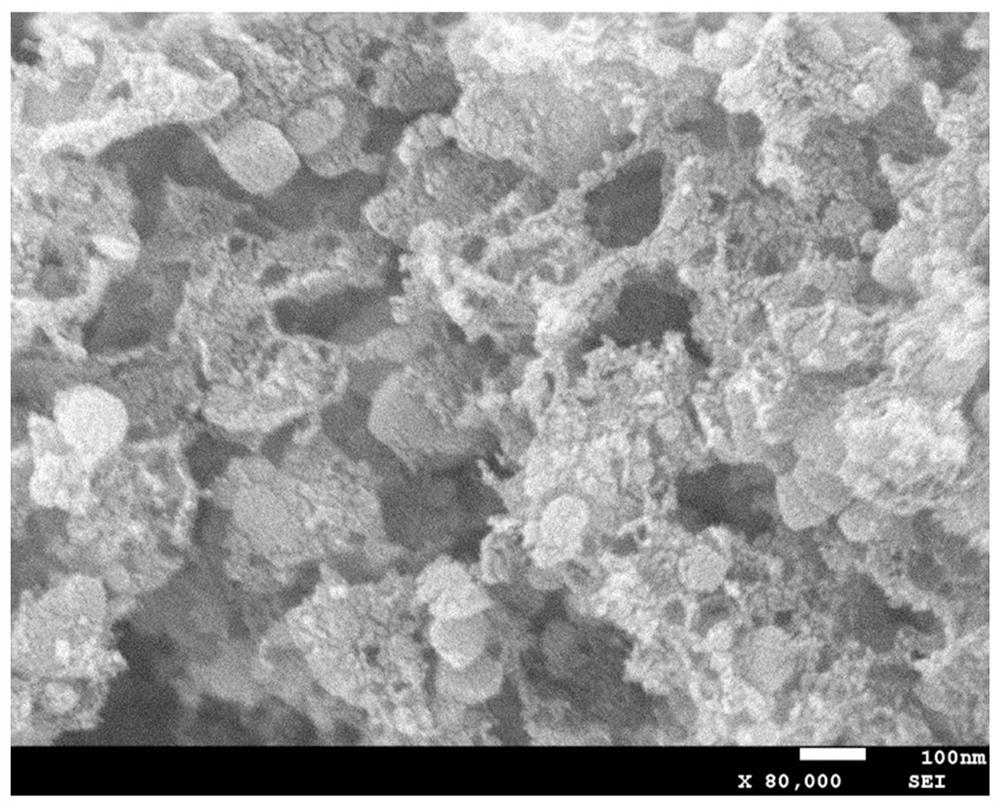

[0031] 6 mmol fe (no 3 ) 3 · 9h 2 O and 1.645 g c 6 Hide 8 O 7 Formation of solution a, 4 mmol NH in deionized water of 20 mL 4 Hide 2 PO 4 And 2 mmol na 4 P 2 O 7 The solution B, 0.15 g of PVP is dissolved in 15 ml deionized water to form a solution C in 15 ml deionized water. The solution A was added to the solution B at a drop of a drop per second, and the boulder was added while drying until it was added, and the solution turned into a yellow-green suspension, i.e., a solution D; then droplets per second. The solution C was added to the solution C, and the stirring was continued for 7 h, and the freezing dryer was subjected to cryogenic dryer, and the pressure was dried under -90 ~ -80 ° C, and the pressure was dried under a pressure of 5 PA. The precursor is obtained; finally, the precursor is placed In the tube furnace, in Ar-H 2 After the mixed atmosphere is predefined at 300 ° C, after 6 h, then 10 h at 500 ° C for 10 h to obtain NA 4 FE 3 (Po 4 ) 2 P 2 O 7 / C composite, ...

Embodiment 1-1

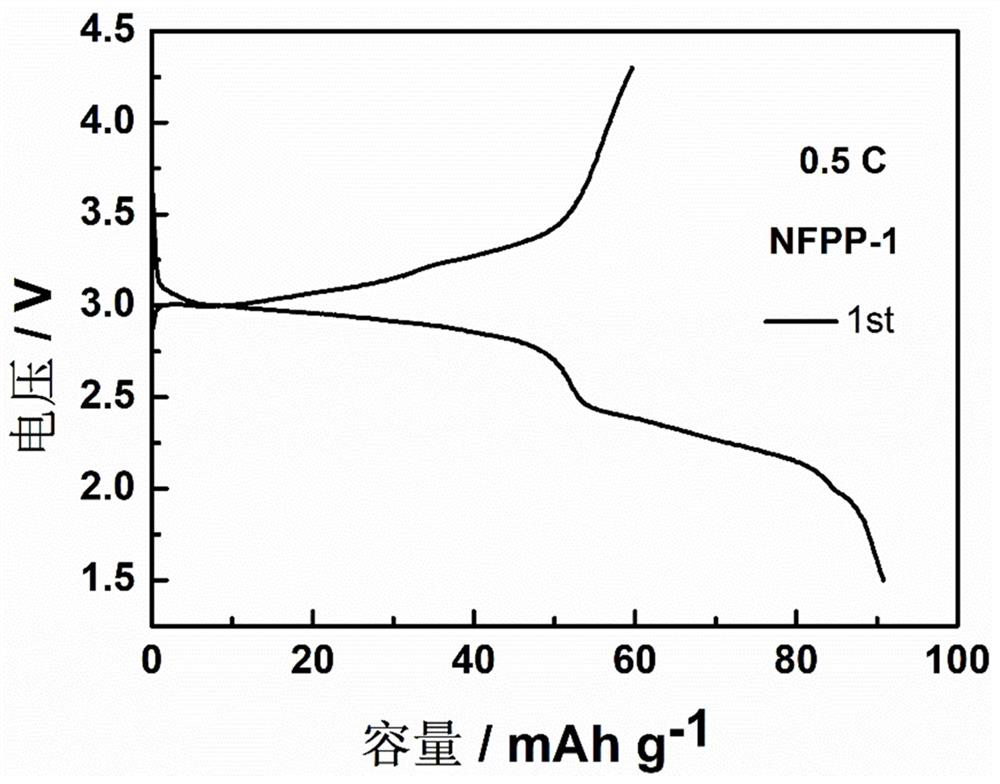

[0033] Implementation steps with Comparative Example 1, only NA + , Fe 3+ And PO 4 3- P 2 O 7 4- The molar ratio of four ions is 4: 3: 1: 1, then NA 4 P 2 O 7 , Fe (NO 3 ) 3 · 9h 2 O, NH 4 Hide 2 PO 4 NA 4 P 2 O 7 8 mmol, 6 mmol, 2 mmol, 2 mmol, get NA 4 FE 3 (Po 4 ) 2 P 2 O 7 / C composite, the first discharge ratio of 90.8 mahg is marked as NFPP / C-1, 0.5 C magnification. -1 After 30 cycles, its discharge ratio is 64.5 MAH g. -1 . From figure 1 In the first charge and discharge curve diagram of NFPP / C-1, we can find that the synthetic NFPP / C-1 relative to NFPP / C has a discharge platform near 2.0 V, indicating that the synthetic NFPP / C-1 is In pure phase, contain other impurities.

Embodiment 1-2

[0035] Implementation steps with Comparative Example 1, only c 6 Hide 8 O 7 With fe (no 3 ) 3 · 9h 2 O The mass ratio is 10: 1, get NA 4 FE 3 (Po 4 ) 2 P 2 O 7 / C composites, labeled NFPP / C-2, 0.1 C magnification of 96.5 MAH g -1 After 30 cycles, its discharge ratio is 87.6 MAH g. -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com