Method for processing composite product with through holes

A technology for composite materials and products, which is applied in the field of through-hole processing by water cutting of composite materials, can solve problems such as scrapping and product defects, achieve the effects of small damage, high pass rate, and prevent product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

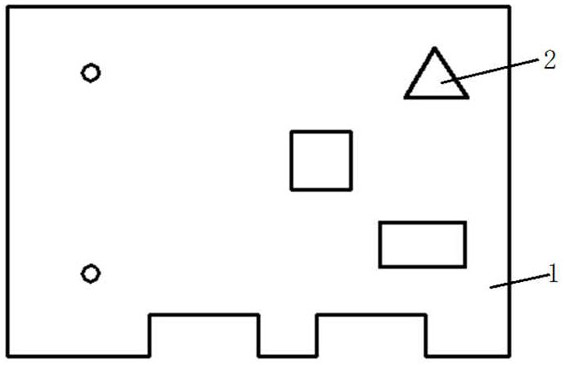

[0021] Composite material product 1 of this embodiment is made of glass fiber reinforced epoxy resin-based composite material, and its structure and shape are as follows: figure 1 As shown, the equal-thickness structure has two notches with a length of 100 mm and a width of 50 mm at the lower end, and five through holes 2 are distributed in the thickness direction, including two circular holes with a diameter of 10 mm, an equilateral triangular hole with a side length of 50 mm, A square hole with a side length of 50mm and a rectangular hole with a length of 80mm and a width of 40mm.

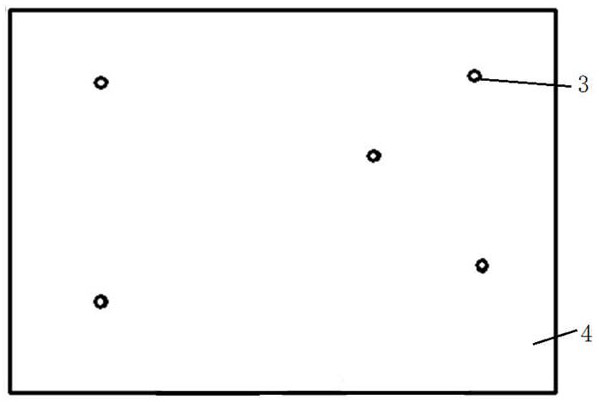

[0022] By measurement, on the glass fiber-reinforced epoxy resin-based composite material rough plate 4 for preparing composite material products, utilize a punching machine to open five through feed holes 3, such as figure 2 As shown, the feed holes 3 are all round holes with a diameter of 2mm, and their relative positions on the composite material blank plate 4 correspond to the relative posit...

Embodiment 2

[0029] The composite material product 1 of this embodiment is made of carbon fiber reinforced epoxy resin-based composite material, and its structural shape is consistent with that of Embodiment 1.

[0030] Prepare a template with the same external dimensions as the composite material product 1, and manually open five round holes with a diameter of 2mm on the template. Corresponds to the inside of the through hole 2.

[0031] Cover the template on the carbon fiber-reinforced epoxy resin-based composite material rough plate 4 for preparing the composite material product 1 with a through hole, and use an electric drill to manually drill a through hole with a diameter of 4 mm on the composite material blank plate 4 corresponding to the round hole of the template. Knife hole 3.

[0032] Fix the composite material rough plate 4 to the operating area of the WJ2040-FB high-pressure water jet cutting machine processing table.

[0033] Design the water-jet walking route map: use Au...

Embodiment 3

[0038] The difference from Example 2 is:

[0039] The opening of the template is completed by using the WJ2040-FB high-pressure water jet cutting machine:

[0040] Design the waterjet walking route map: use AutoCAD software to draw a two-dimensional map including the outer contour of the template and the centers of the five circular holes, and define the waterjet traveling route and the cutting position of the outer contour of the template in the two-dimensional map.

[0041] Read the water jet walking route map into the WJ2040-FB high pressure water jet cutting machine program.

[0042] Fix the PC board with a thickness of 2mm to the operating area of the WJ2040-FB high-pressure water jet cutting machine processing table.

[0043] Start the water jet cutting machine, and set the read-in water jet travel route map as the water jet processing program. Start the waterjet head and run the waterjet processing program. First, locate the origin of the waterjet head according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com