Rolling mill loop roller swing rotation angle detection system and control method thereof

A technology for angle detection and looper rolls, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as production efficiency drop, looper encoder damage, production interruption, etc., to ensure plan execution rate and Specification fulfillment rate, guarantee stability and smooth progress, and reduce the effect of failure impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

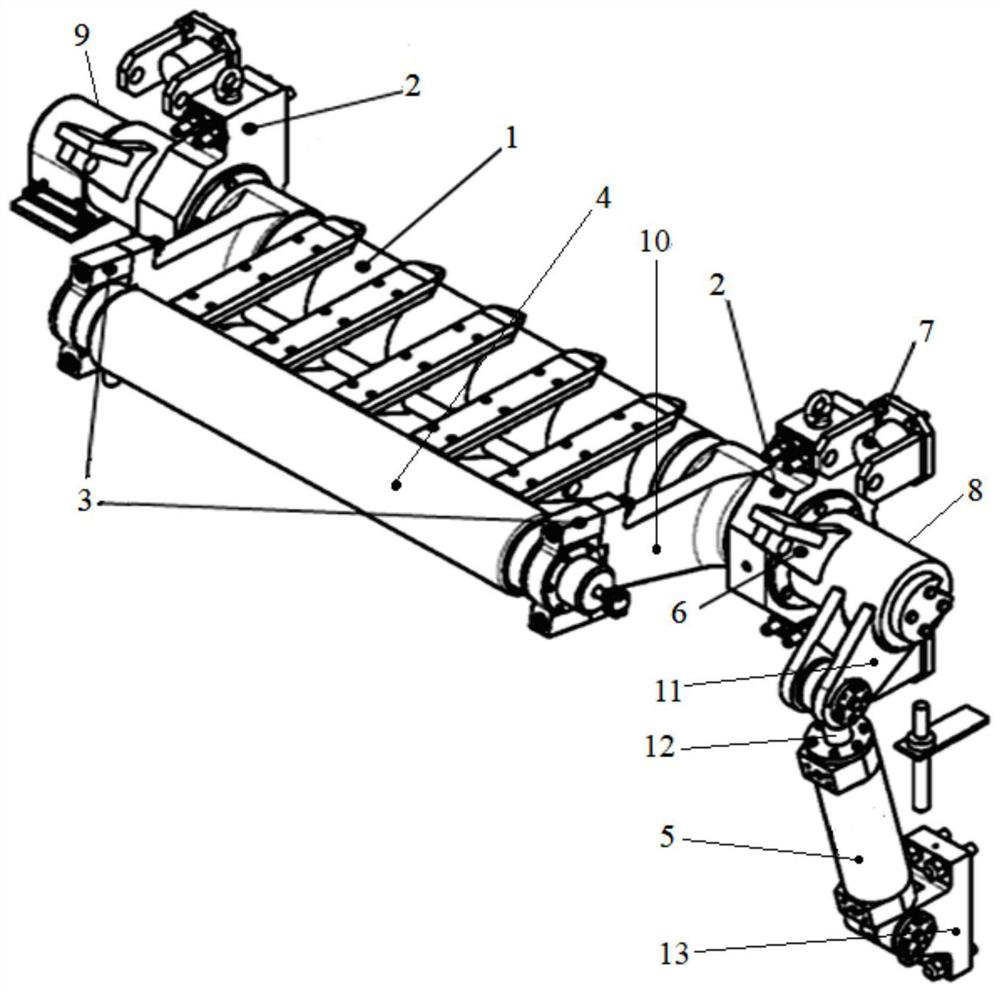

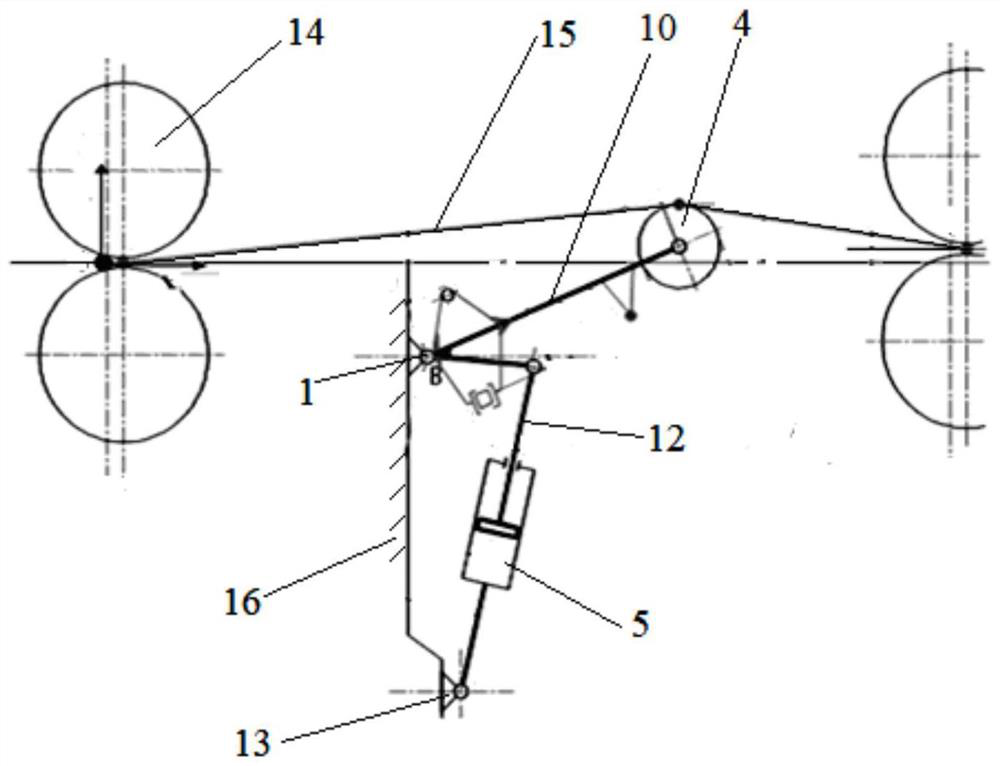

[0018] like figure 1 , figure 2 The structure of the present invention shown is a rolling mill looper roll swing angle detection system, which adopts the control strategy of online standby and fast switching of the rolling mill looper encoder; in order to make the tension and rolling speed between the stands change synchronously (Balancing the logistics between the rolling mills), the lower surface of the strip steel forms a bend by contacting the looper roll 4, and accumulates between the racks in a curved form and changes in time.

[0019] Described looper roller 4 is installed on the swinging arm 10 of looper roller through lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com