A flexible printed circuit board

A flexible printed circuit, circuit board technology, applied in printed circuit components, printed circuit stress/deformation reduction, circuit safety components, etc., can solve the problem of poor durability and safety, the structure cannot be used normally, insulation and Insufficient flame retardant performance and other problems, to achieve the effect of improving safety and durability, convenient and stable line docking and installation work, and enhancing tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

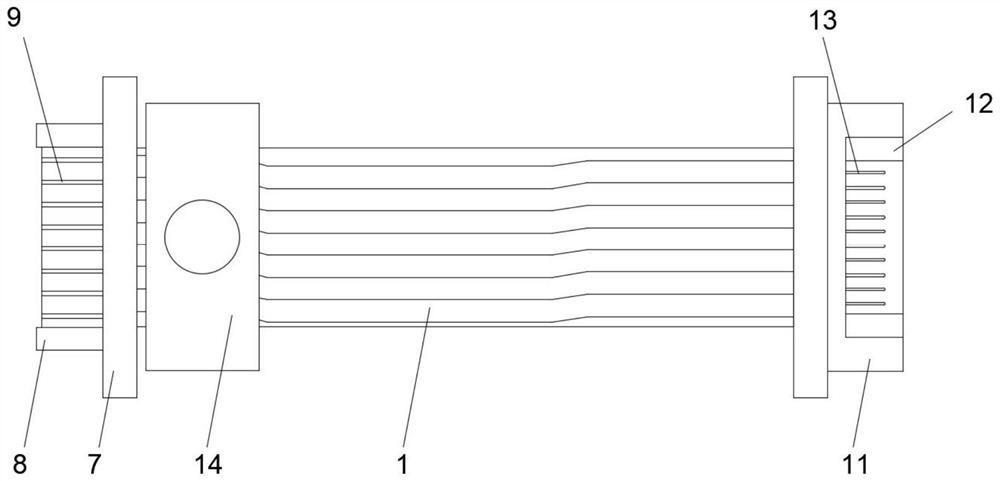

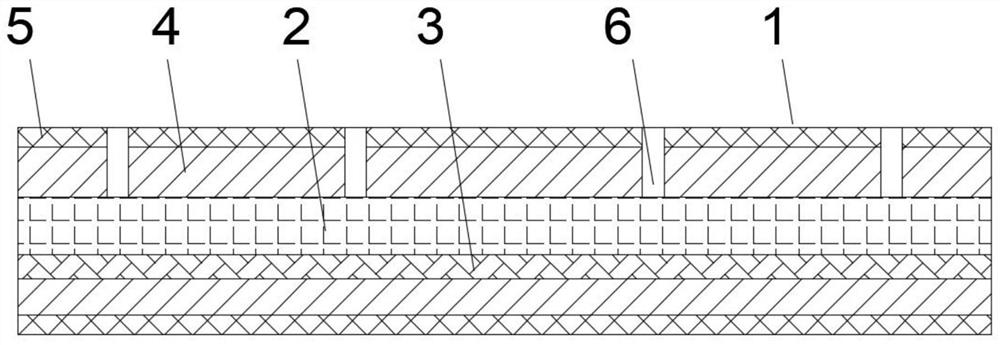

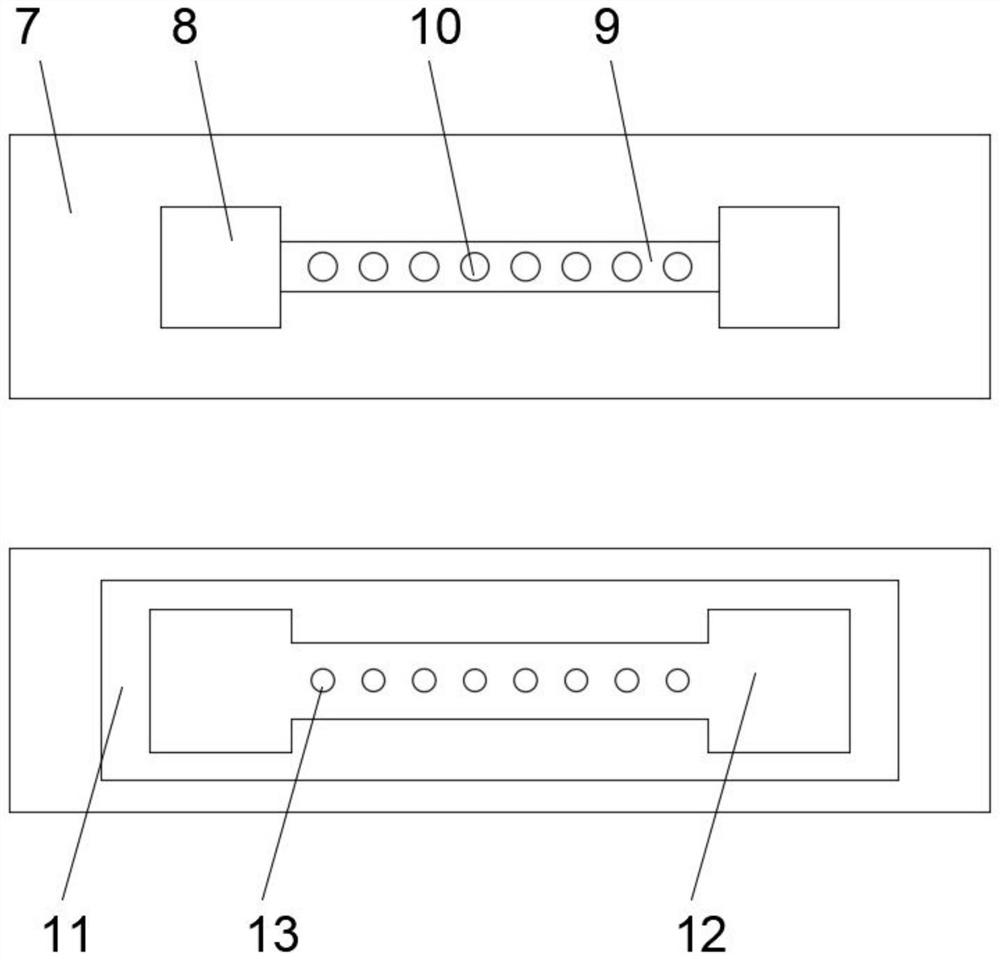

[0027] like Figure 1-5 As shown, an embodiment of the present invention provides a flexible printed circuit board, comprising a circuit board body 1, a base layer 2 is arranged in the circuit board body 1, a reinforcement layer 3 is arranged at the bottom of the base layer 2, and the top of the base layer 2 is connected to the reinforcement layer 3 The bottom of the circuit board is provided with an insulating layer 4, the outer surfaces of the two insulating layers 4 are provided with a flame retardant layer 5, and both ends of the circuit board body 1 are provided with a connecting frame 7, and one side of the outer surface of one connecting frame 7 is fixed. A rear clamping block 8 is connected, the clamping block 8 is provided with a connecting piece 9, and a plurality of connecting holes 10 are evenly distributed on the connecting piece 9, and the outer surface of the other connecting frame 7 is fixedly connected with a connecting head 11, connecting the The outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com