Bending-torsion-resistant cable special for mechanical arm and manufacturing method thereof

A technology of a special cable and a manufacturing method, which is applied in the special cable of a bending-resistant torsion mechanical arm and its manufacturing field, and can solve problems such as bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

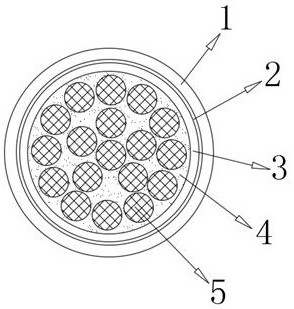

[0026] The special cable for bending and torsion-resistant mechanical arms includes a conductor wire 5 and an outer sheath material, and the outer sheath material includes a silicone rubber outer sheath layer 1, a flexible rubber sheath 2 and a silicone rubber inner sheath layer 3, And the flexible rubber sheath 2 is located between the silicone rubber outer sheath layer 1 and the silicone rubber inner sheath layer 3 , and the graphene filling layer 4 is filled between the conductor wires 5 .

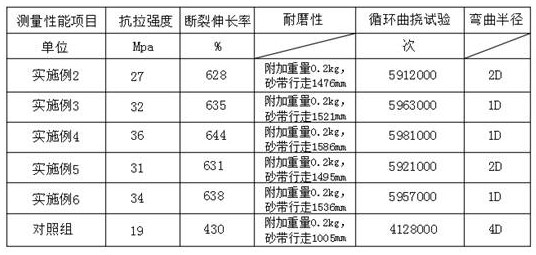

Embodiment 2

[0028] A bending-resistant torsion-resistant mechanical arm special cable as described in Example 1, its preparation method is as follows:

[0029] Mix zeolite and cetyltrimethylammonium bromide in a weight ratio of 1:0.5, stir at 120°C for 1 hour to obtain a modified zeolite with a particle size not greater than 0.1mm;

[0030] Weigh the materials according to the following parts by weight: 8 parts of modified zeolite, 8 parts of mineral oil, 1 part of tetrachlorethylene, 1 part of white carbon black, 0.3 part of glass microspheres, 0.5 part of trimethylsiloxane, 30 parts of natural rubber 6 parts of butadiene rubber, 1 part of microcrystalline wax, 1 part of zinc oxide, 1 part of stearic acid, 2 parts of toughening agent;

[0031] Fully mix mineral oil, tetrachlorethylene, white carbon black, glass microspheres and trimethylsiloxane to obtain a mixture A; put the modified zeolite into a calciner at a temperature of 450°C for calcining to obtain a calcined zeolite; Add mixtu...

Embodiment 3

[0034] A bending-resistant torsion-resistant mechanical arm special cable as described in Example 1, its preparation method is as follows:

[0035] Mix zeolite and cetyltrimethylammonium bromide in a weight ratio of 2:0.7, and stir at 150°C for 1.5 hours to obtain a modified zeolite;

[0036] Weigh the materials according to the following parts by weight: 11 parts of modified zeolite, 10 parts of mineral oil, 2 parts of tetrachlorethylene, 3 parts of white carbon black, 0.6 part of glass microspheres, 1.2 parts of trimethylsiloxane, 37 parts of natural rubber 8 parts of butadiene rubber, 3 parts of microcrystalline wax, 1.5 parts of zinc oxide, 3 parts of stearic acid, 4 parts of toughening agent;

[0037] Fully mix mineral oil, tetrachlorethylene, white carbon black, glass microspheres and trimethylsiloxane to obtain a mixture A; put the modified zeolite into a calciner at a temperature of 500°C for calcining to obtain a calcined zeolite; Add mixture A to calcined zeolite and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com